Background

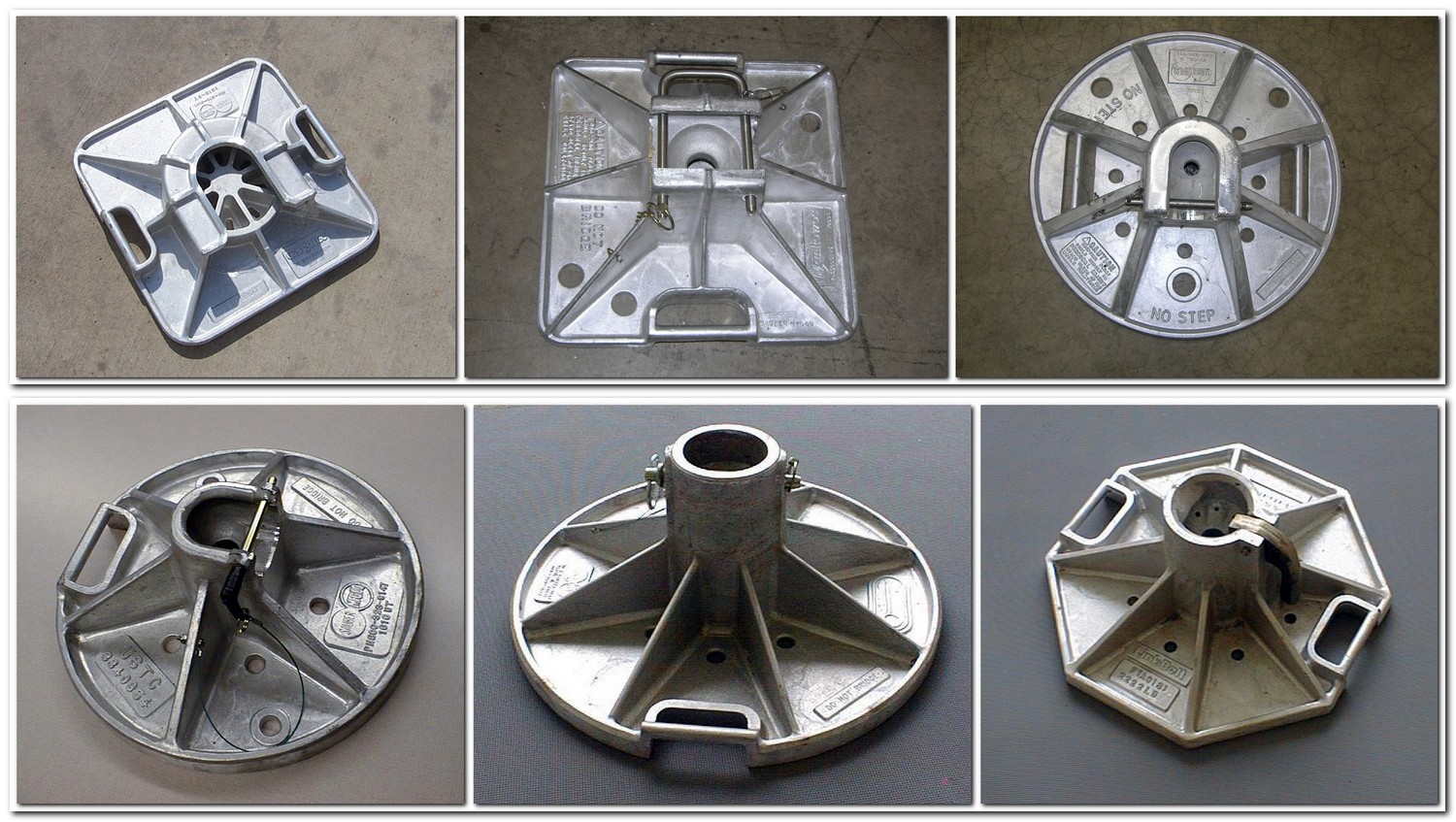

Sauber Mfg. Co. develops specific crane pads and other hardware based on each OEM application. Our approach is to provide a turnkey solution to your pontoon needs by incorporating the pad and attachment head into a single casting, delivered complete, and on time. This method eliminates the necessity for the OEM to utilize costly production time fabricating steel pads or adapters to fit forged aluminum bases. By allowing us to design the pontoon from the ground up, you get a pad that is exactly right for your application.

For each application, a pad is selected to meet your load and floatation requirements. If we don’t have an implementation that fits your needs, we’ll use solid modeling to design an Almag pad for your specific OEM application.

Why Almag? It has the highest strength to weight ratio of any as-cast aluminum. This reduces operator fatigue and stress when handling pads and machine capacity is maximized because total weight is lowered. Learn more: Almag 35 Properties

Benefits

- 3-Year guarantee with a date stamp provides additional customer value in your marketplace.

- The entire pad is non-rusting, including stainless steel fasteners.

- Cast pads are the same every time, free of manufacturing variances.

- Your part number, logo, or other identification can be cast directly into the pad for high recognition and life-time identification.

- Eliminates plant utilization required to produce or up fit outrigger pads.

- Reduces logistic headaches from coordinating manufactured and purchased components time lines.

- Solids drawings allow your engineering staff to concentrate on core competencies.

- Gains the security of doing business with a 3A1 company with a track record of reliable, on-time delivery allowing you and your staff to concentrate on running your business unit and not following up on vendors.

- A single vendor providing all products, support, and technical data reduces communication and acquisition costs.

- With the ability to handle aluminum extrusions and all types of castings, Sauber is capable of being your OEM supply powerhouse.

Bridging and Design Capacities

Although we recognize that bridging can happen inadvertently in the field, the practice is never recommended. An article in Lift Equipment Magazine states “Pontoons need to be level and supported across the entire bottom surface. The entire bottom surface of the pontoon must be covered or uneven stress will cause premature pontoon failure.” Bridging will certainly shorten outrigger pad life, but more importantly, it is unsafe and could result in a condition of instability.

Since surfaces under the pad may vary from one area of the pad to another, it is understood that stress concentrations will exist under portions of the pontoon. To accommodate this, our standard pad design model provides for 100% of the maximum pad load applied in a bridge condition where the unsupported surface area of the pad equals 56% of the total pad area. We can design pads for requirements exceeding 100,000 lbs per pad. We can also model the pad design based on a percentage factor over the maximum pad load, assuming an even distribution, such as 150%. Without additional direction from you, we will utilize our standard model.

Aluminum Magnesium Castings (Almag)

Sauber Outrigger Pads are sand cast from Almag 35. We run over 200 tons of Almag each year, making us the most trusted choice in crane pads. Our Almag castings are high purity, virgin aluminum alloy with exceptional dimensional stability. Almag possesses the highest and most stable combination of strength and shock resistance of any as-cast, non-heat treated aluminum alloy. These properties are developed immediately upon casting – no heat treatment or natural aging is required. There is no degradation of properties through time. Almag is also 10% lighter than average aluminum casting alloys.

Pad Replacement Recommendations

Pads should generally be replaced when any of the following are evident:

- Any visual cracks in or near the rib area.

- Pad bottom deformation covering more than 20 sq-in.

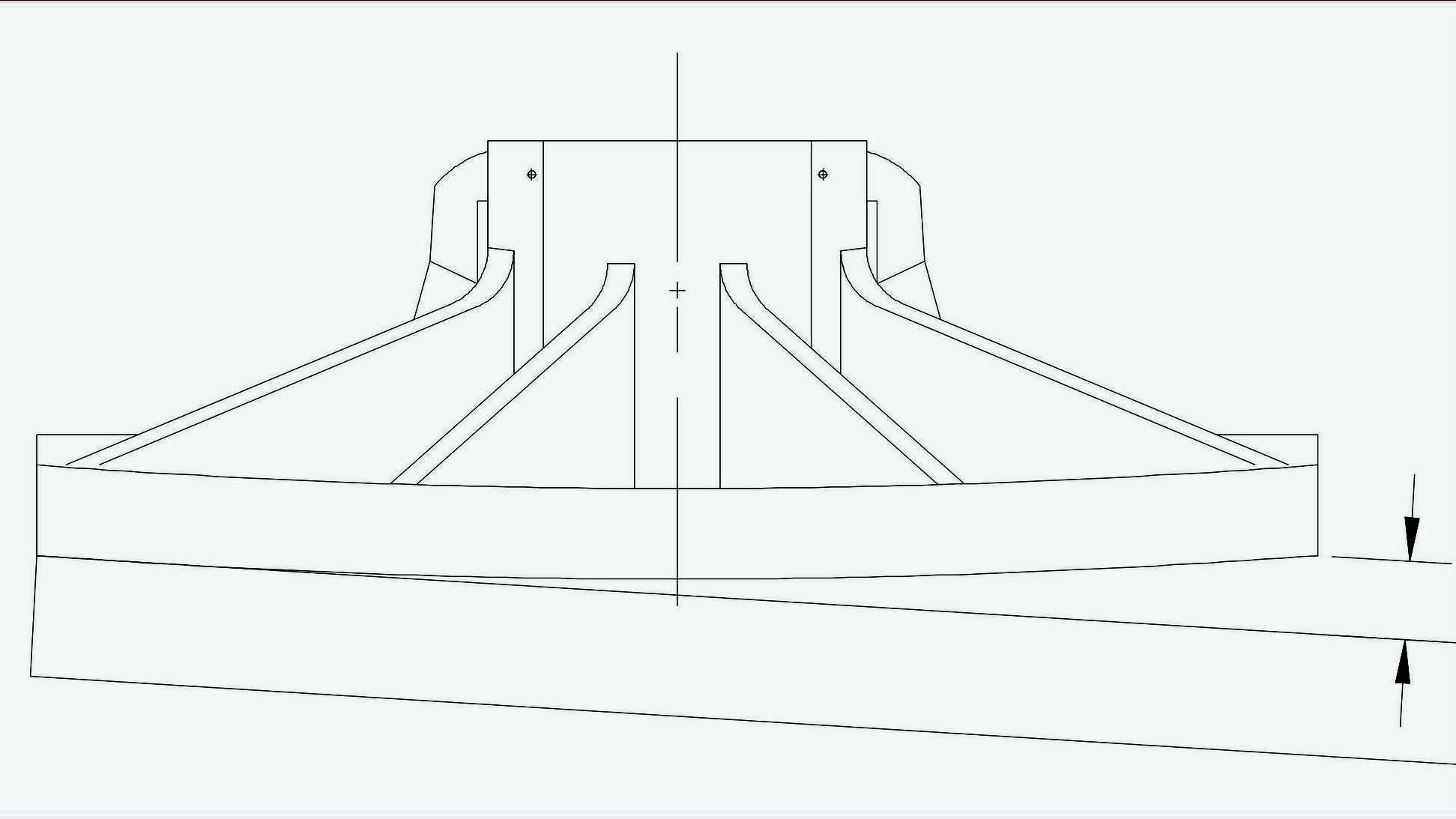

- Deflection that exceeds 3/4″ as measured in the drawing in the gallery below.