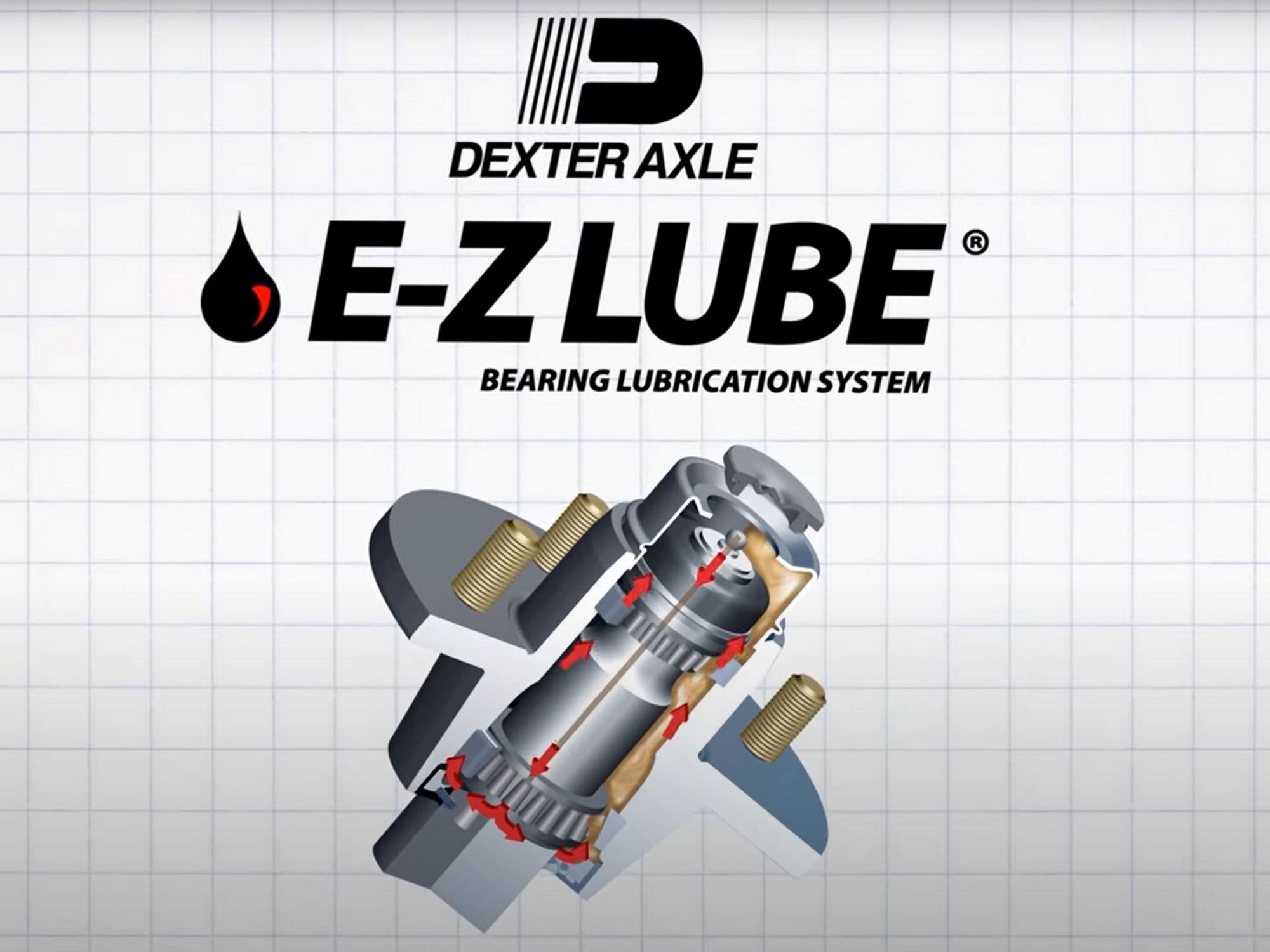

E-Z Lube hubs from Dexter are standard equipment on all trailers we manufacture that utilize grease-type hubs. Axles with capacities of 8000 LBS and above will continue to be equipped with oil bath hubs. These hubs improve maintenance productivity and increase “up time” in field operations.

Benefits of EZ-Lube Hubs include:

- Grease flows to both outer and inner bearings for a complete repack with no mess.

- Rubber Plug eliminates potential to deform metal grease cap while removing.

- No disassembly keeps in-service times up and maintenance costs down.

- Complete lubrication provides submersible bearing protection.

- Will not require specification changes because your Sauber trailers will have it included automatically.

Note: Always inspect and grease hubs per recommendations outlined in Dexter’s Service Manual