Self-Loading Reel Trailer

Model 1506-B

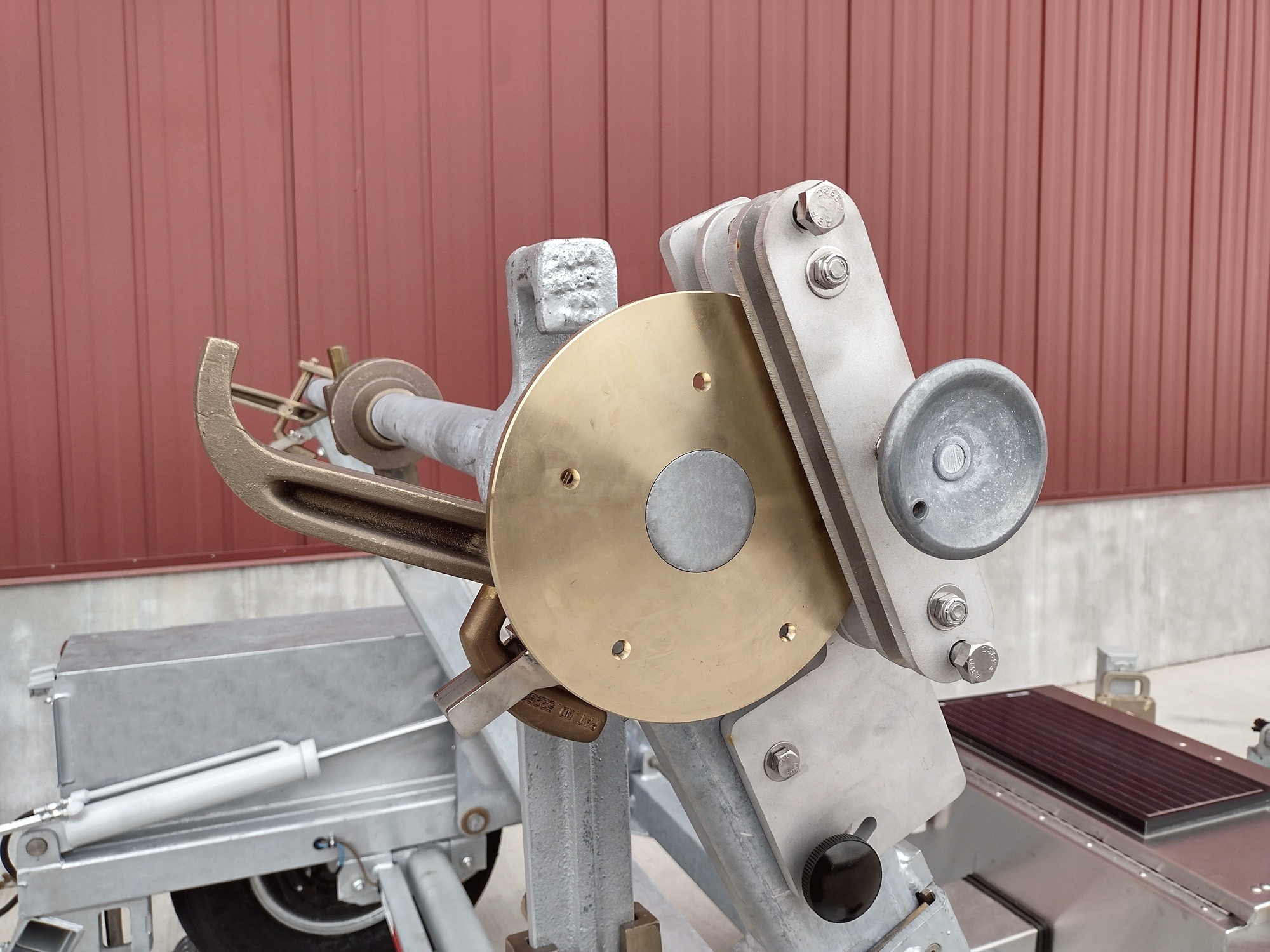

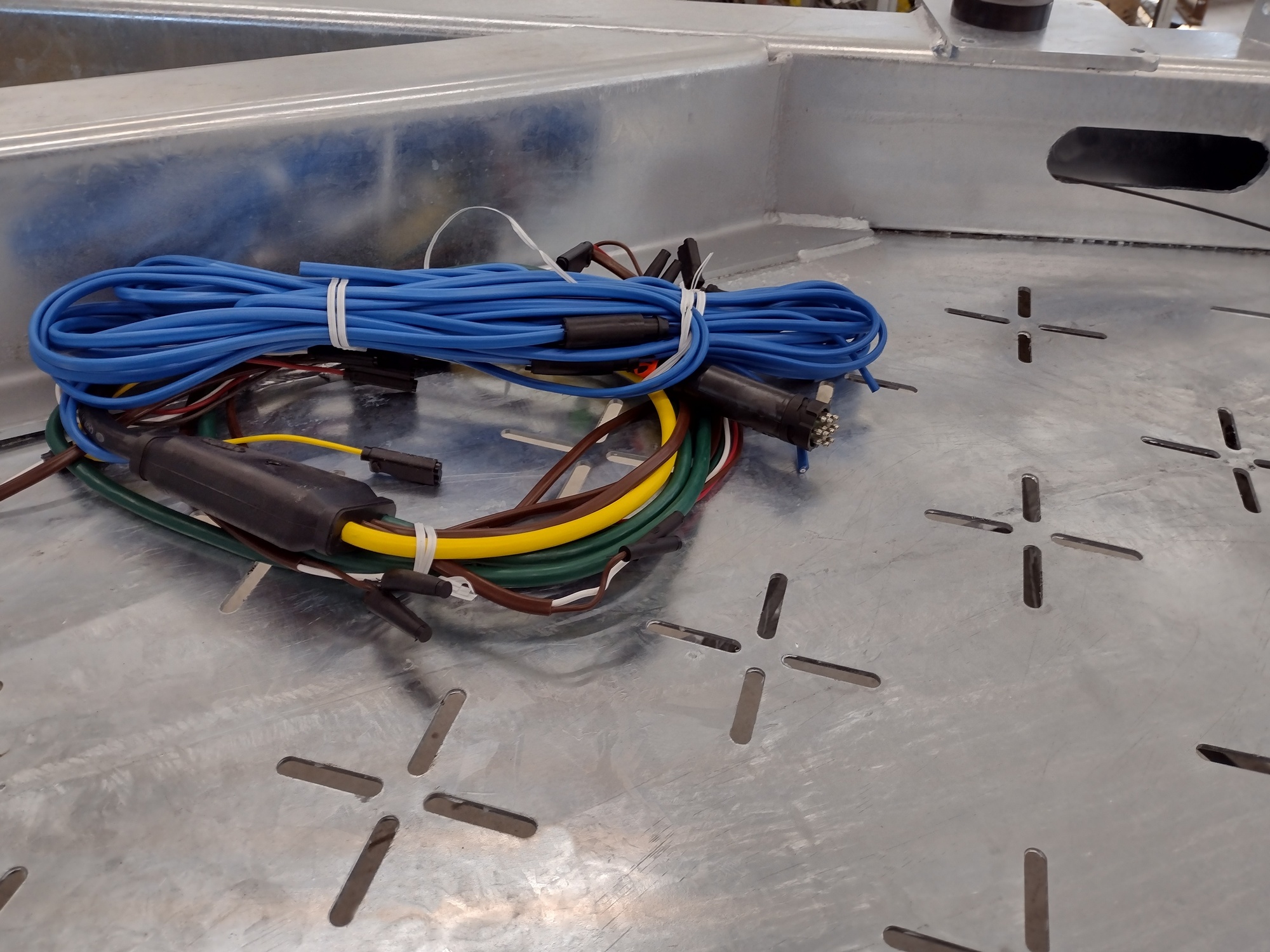

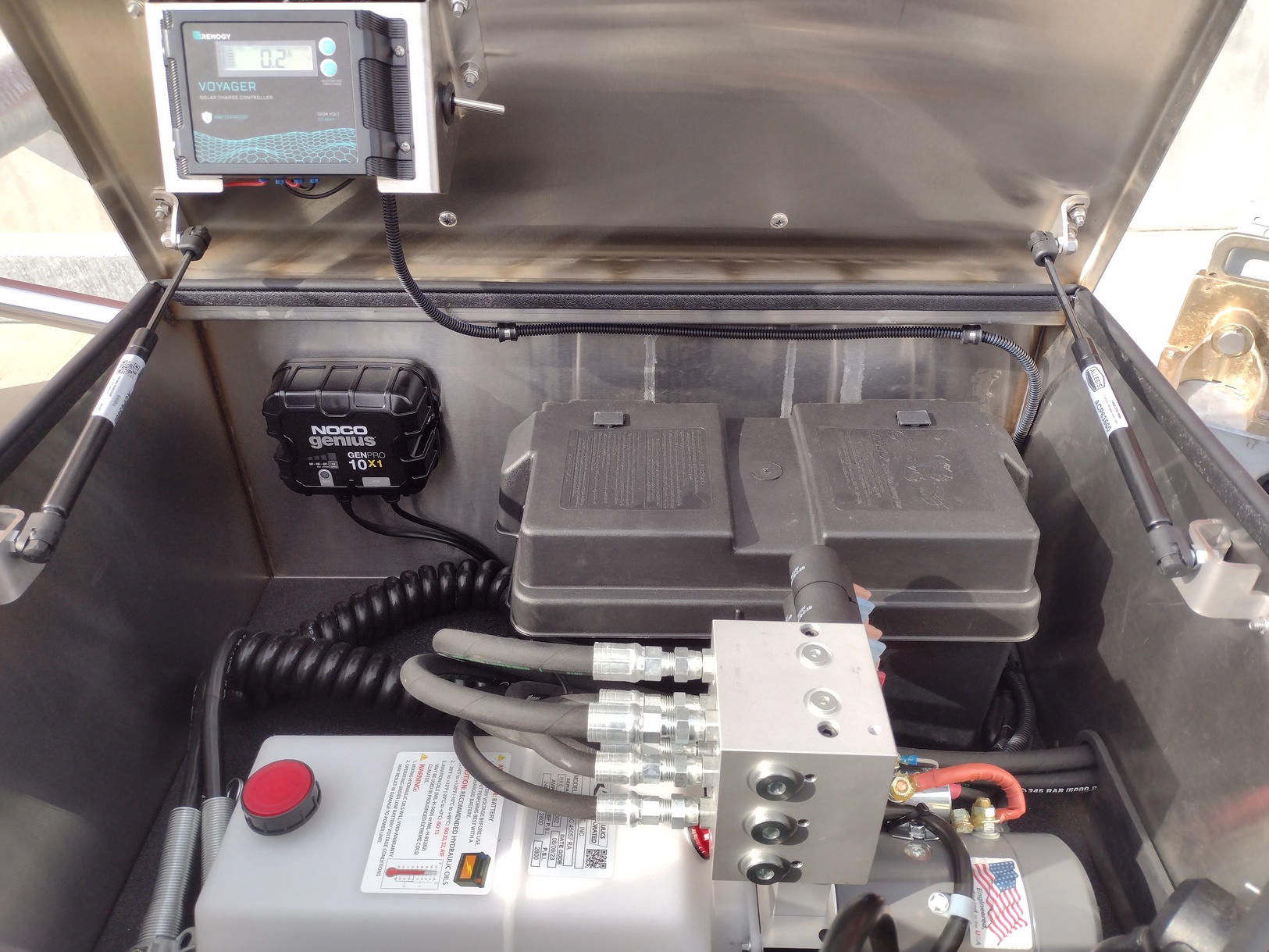

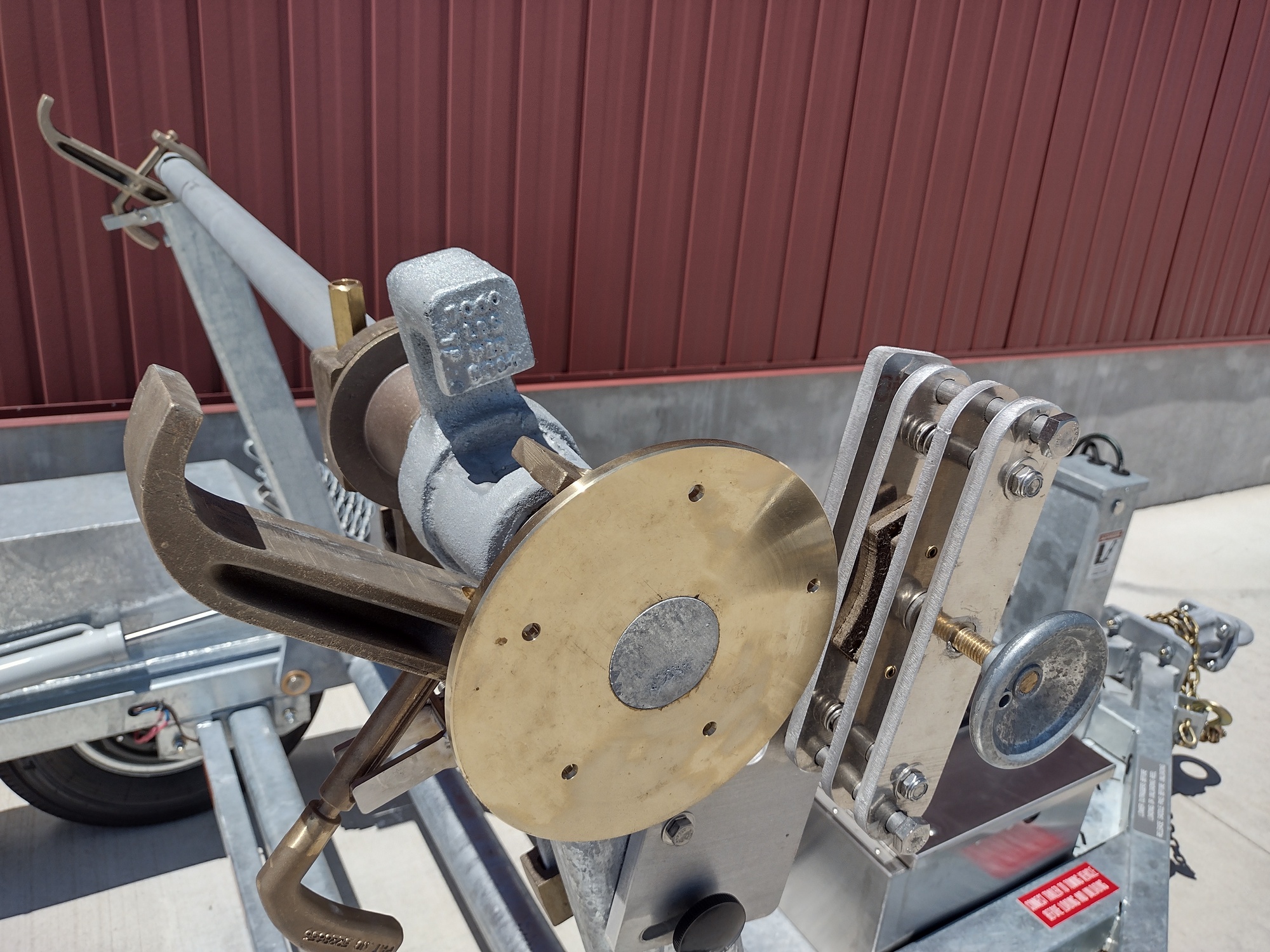

Get work done with a self-loading reel trailer in a size that's suitable for towing with a supervisor’s truck. No need for a forklift or hoist. Reels are conveniently loaded via on demand pendant controlled 12VDC electric/hydraulic power. Like all equipment we build, this Sauber Mfg. Co. trailer is ready for a long productive life with galvanized finish right down to the axle beam and wheels.

Click Here to see other trailers in this category.

Capacity: 6150#

GVWR: 7950#

Reel Size: 82"Dia x 50"W

Dimensions: 12'L x 96"W