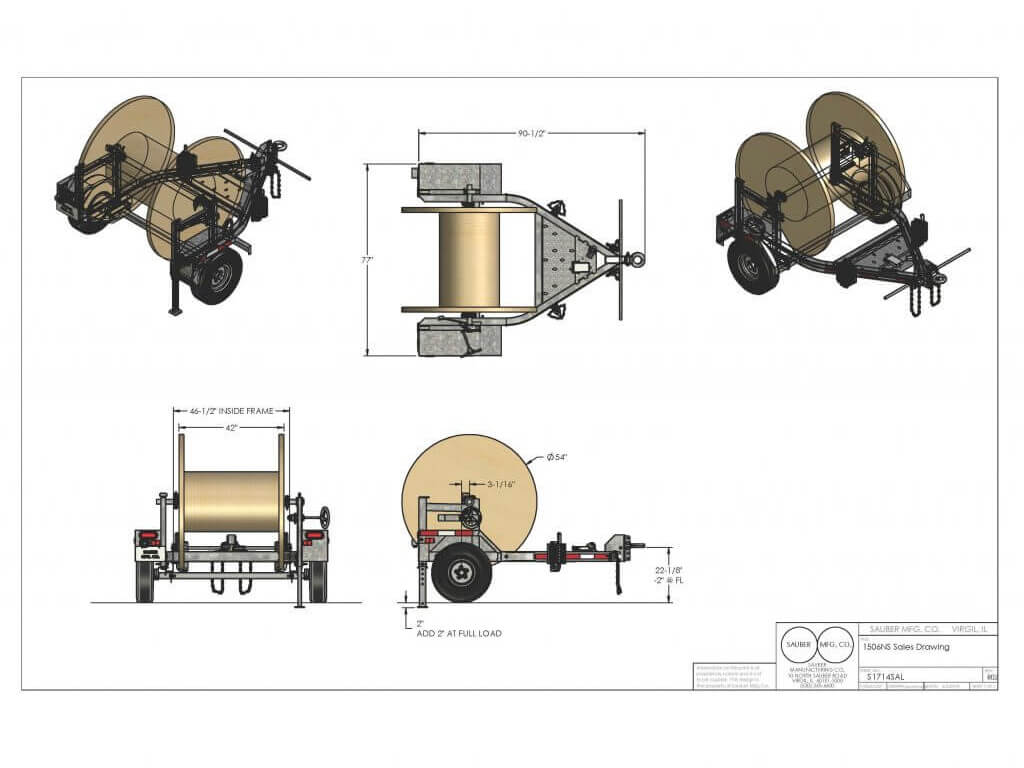

Manual Self-Loading Reel Trailer

Model 1506-NS

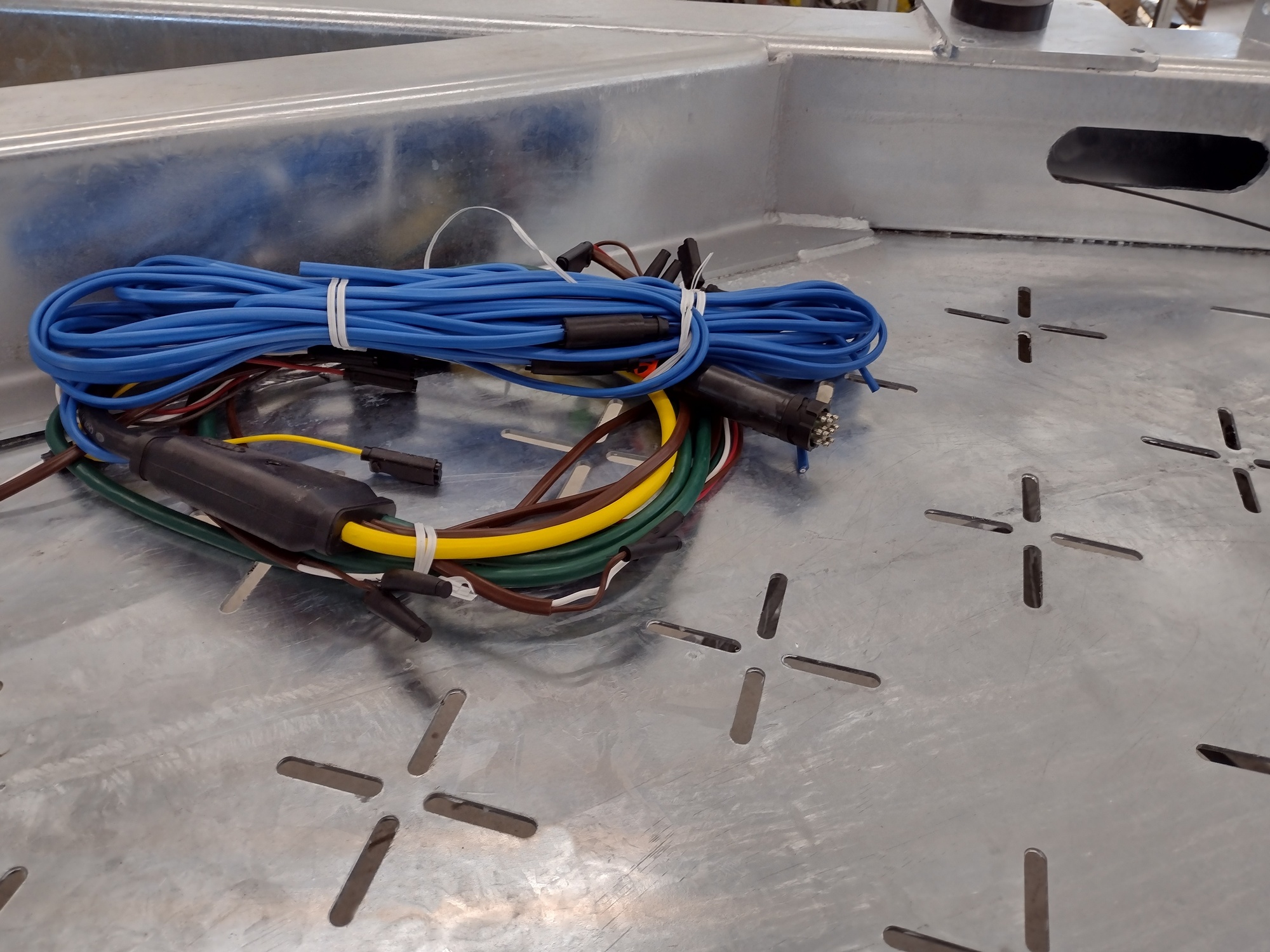

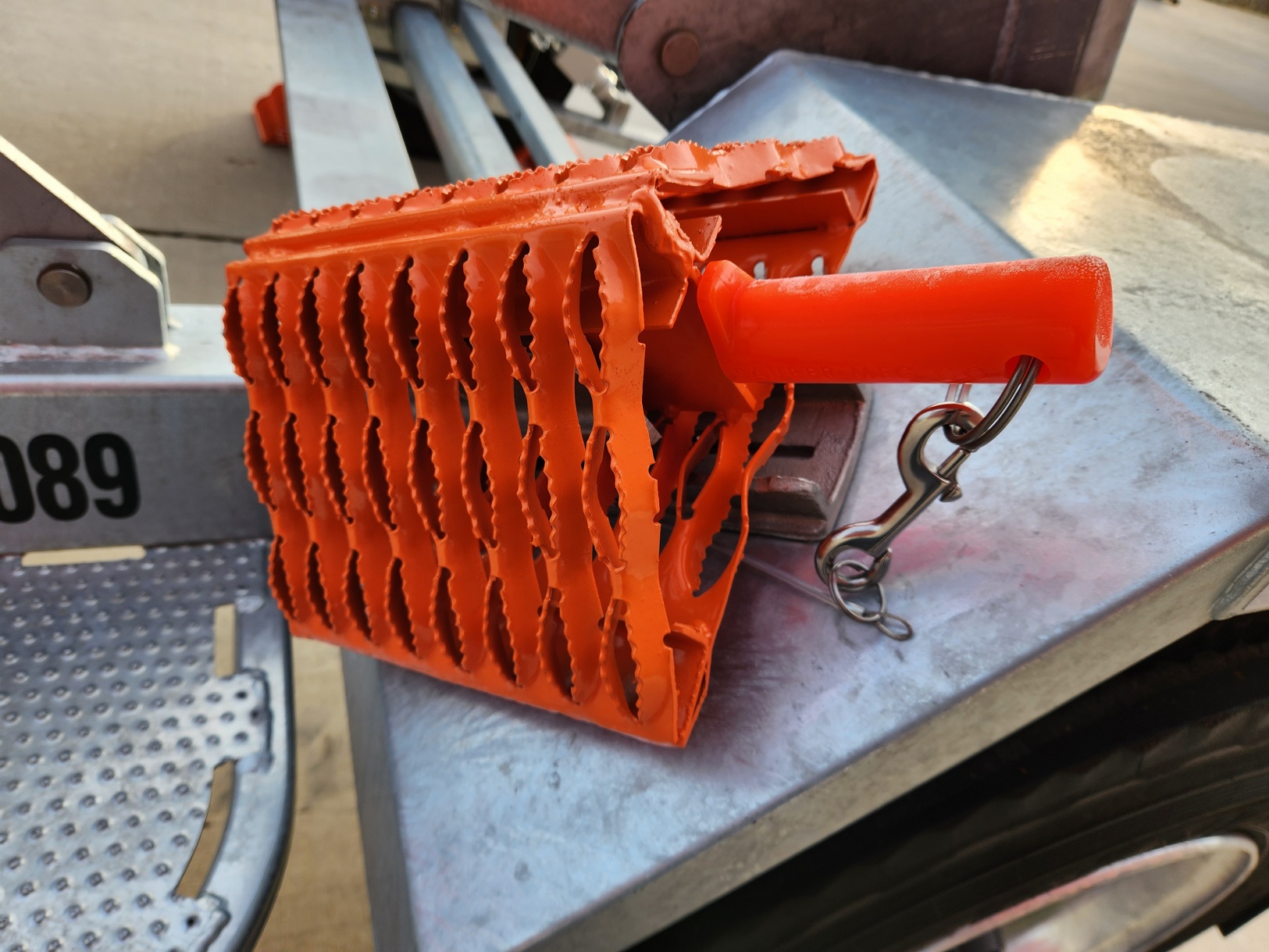

With straightforward, durable construction, this trailer provides manual self-loading and transport of your smaller reel sizes. With geometry designed to provide correct leverage, your crews can easily load up and get right to the job site. And with Sauber standard features like hot dipped galvanized finish, premium wiring and serviceable components, the Model 1506-NS Self Loading Reel Trailer will serve for years to come.

Click here to view similar equipment.

Capacity: 1860#

GVWR: 2400 lbs

Reel Size: 54"Dia x 42"W

Dimensions: 9'L x 77"W