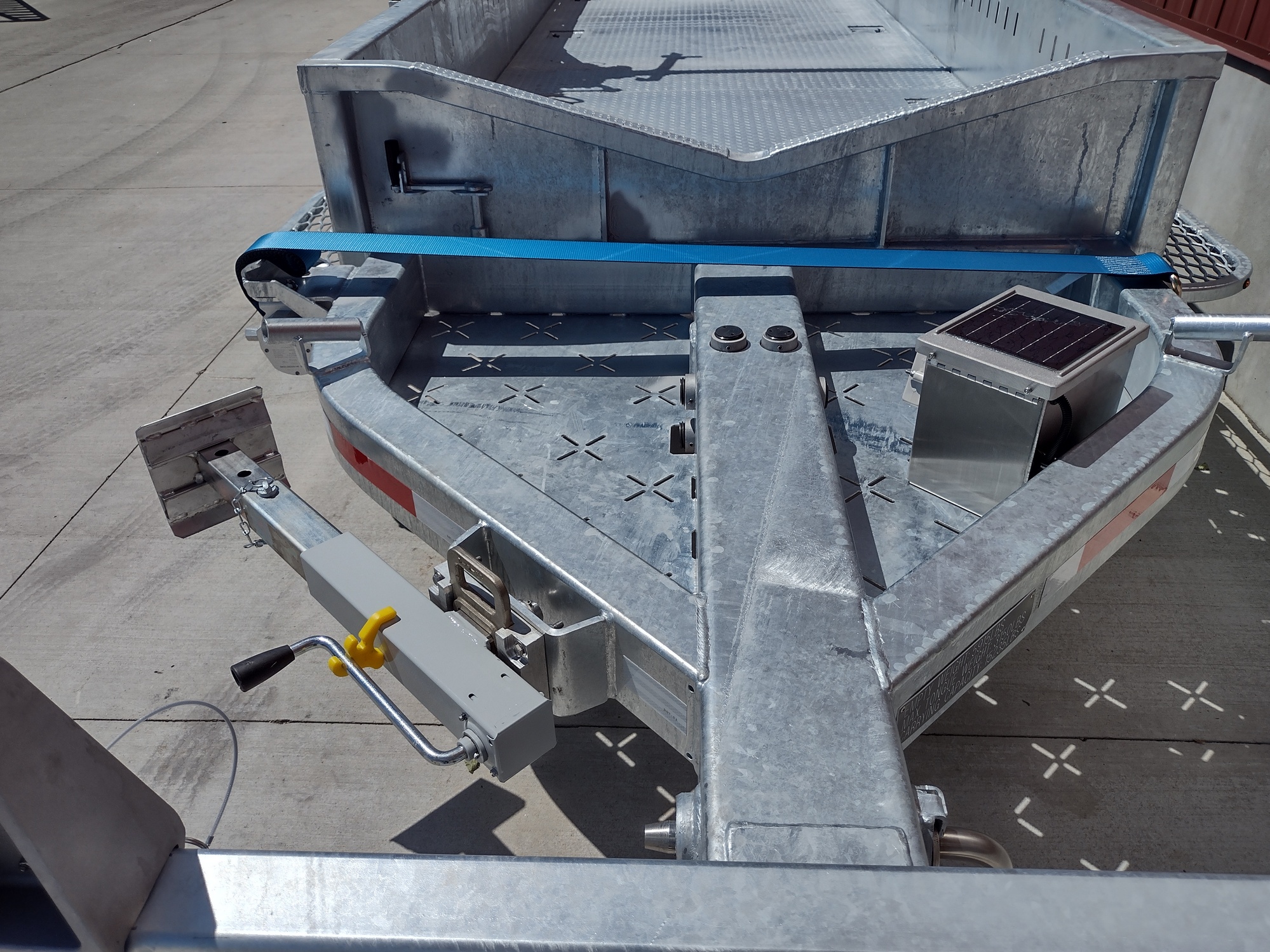

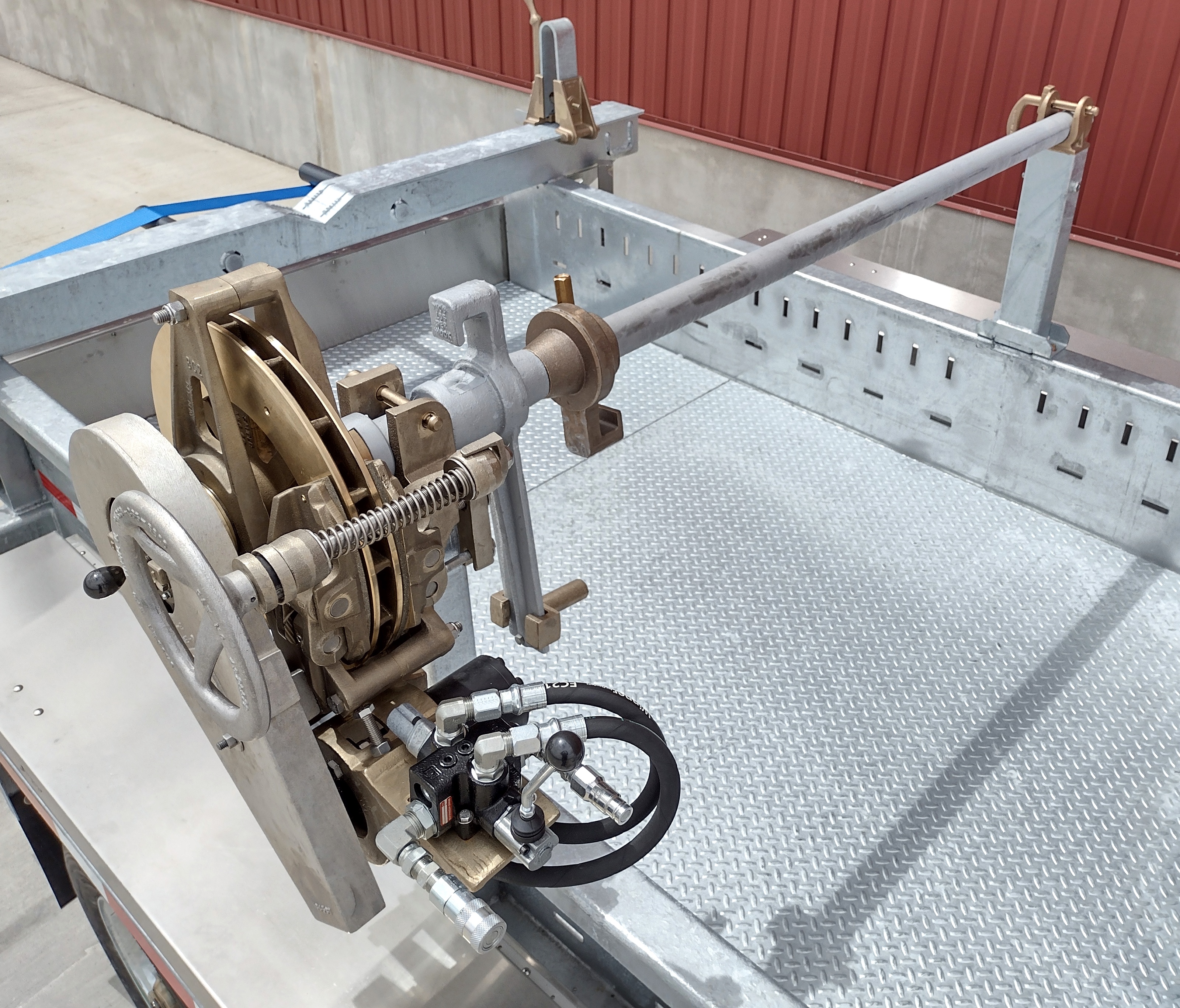

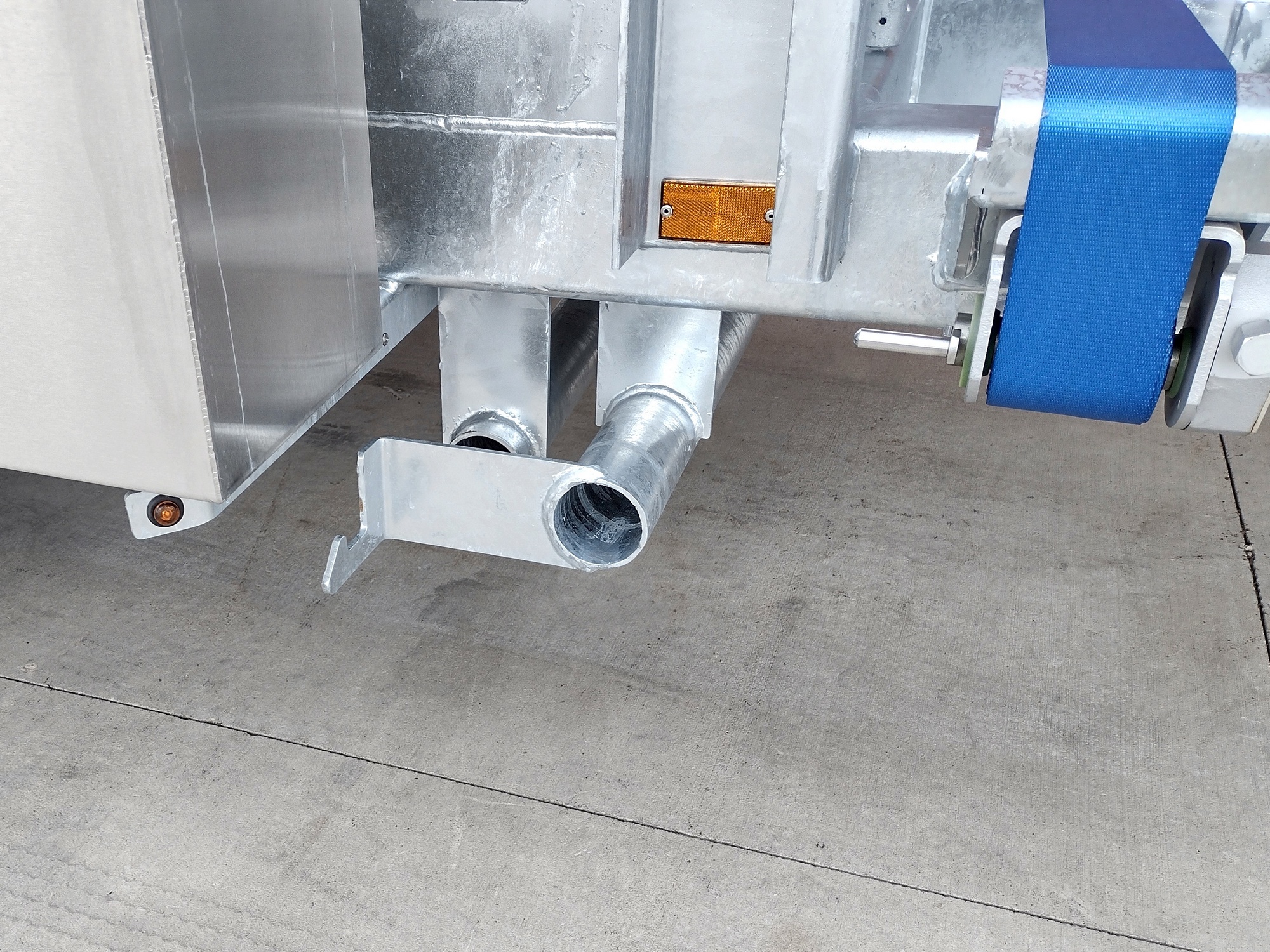

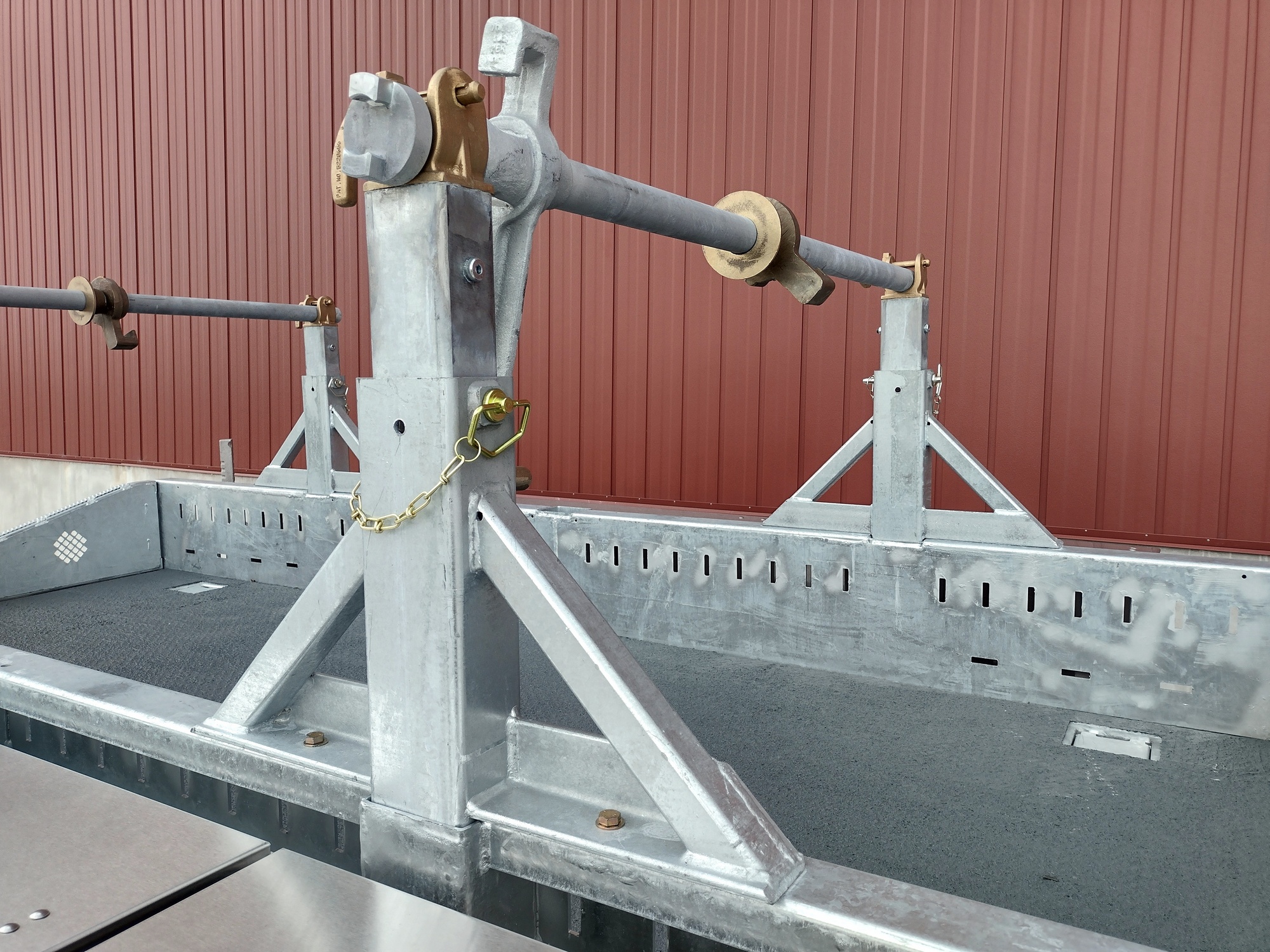

Pole Reel & Cargo Trailer

Model 1521-PRC

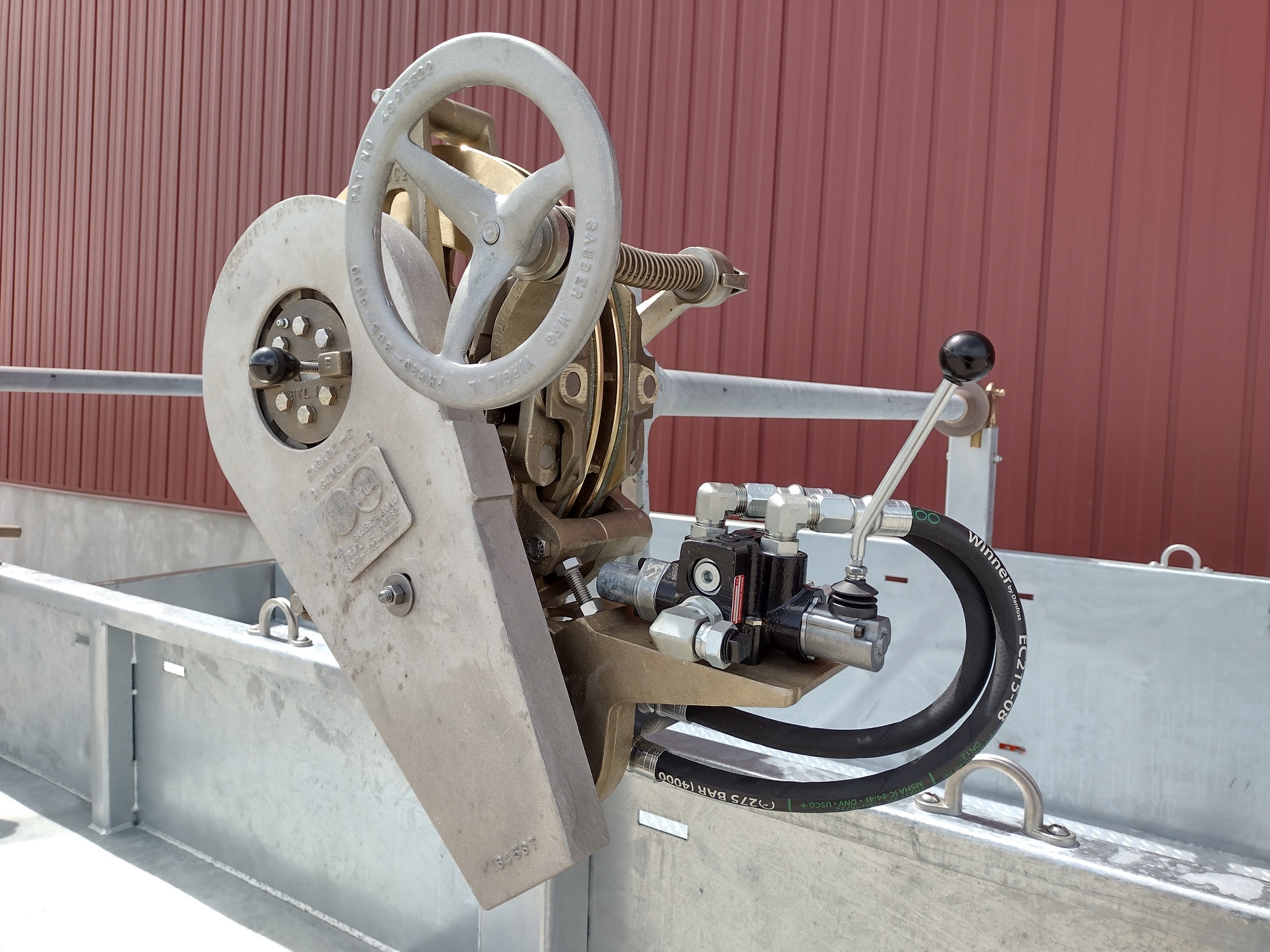

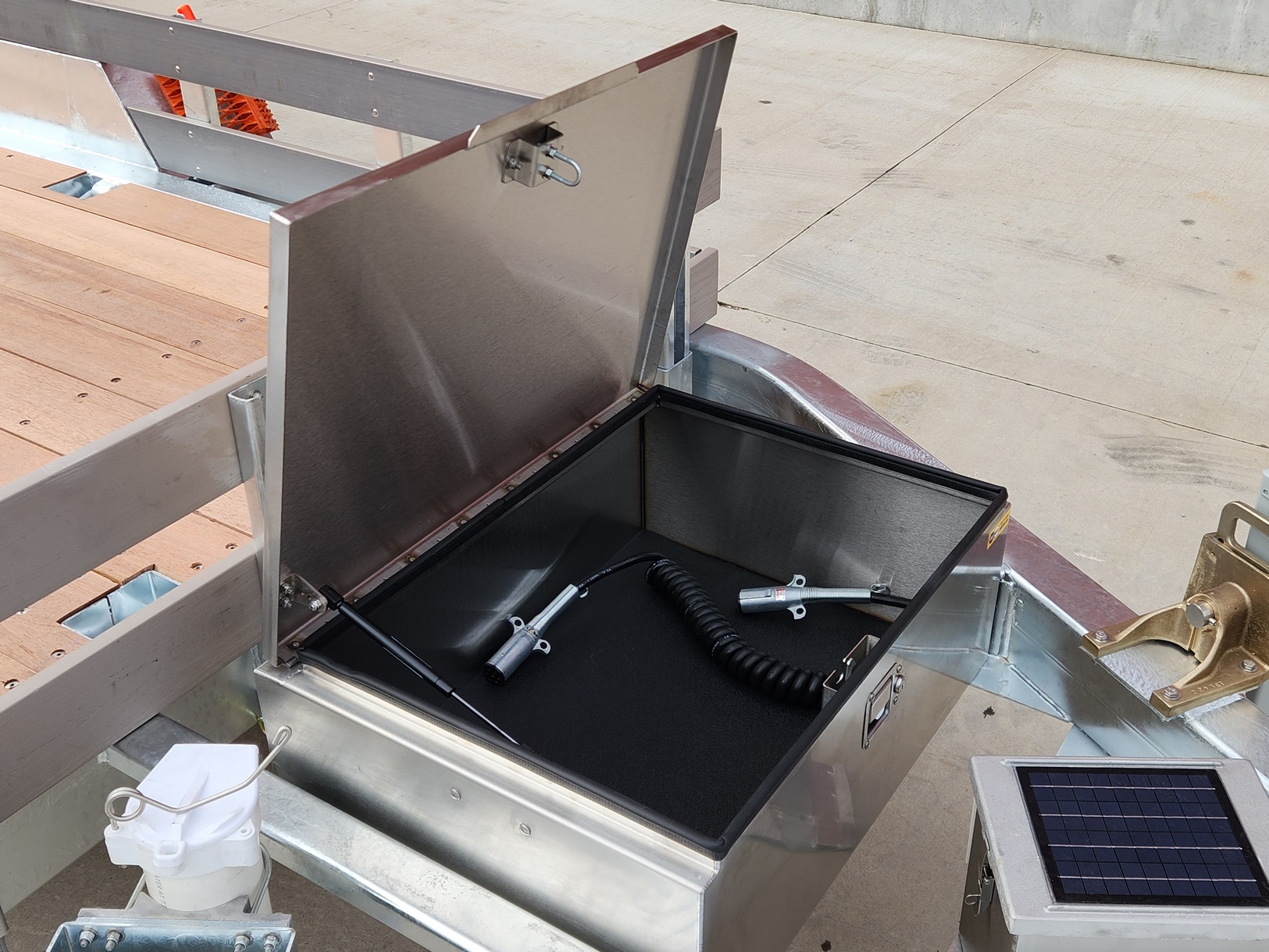

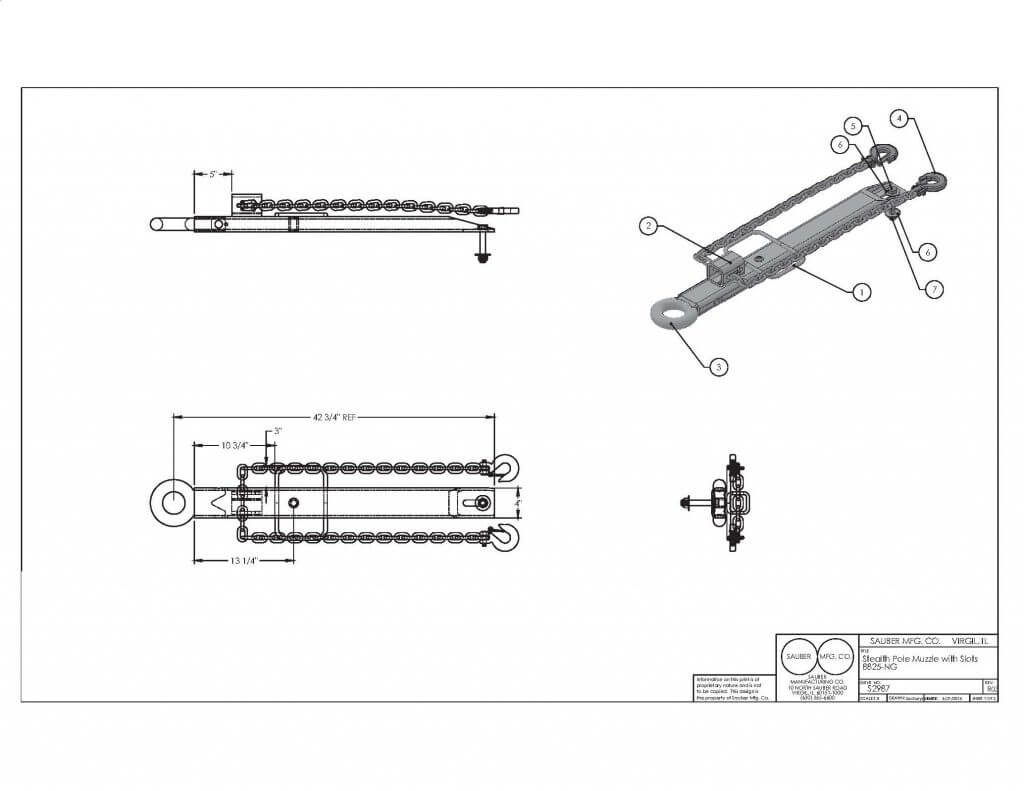

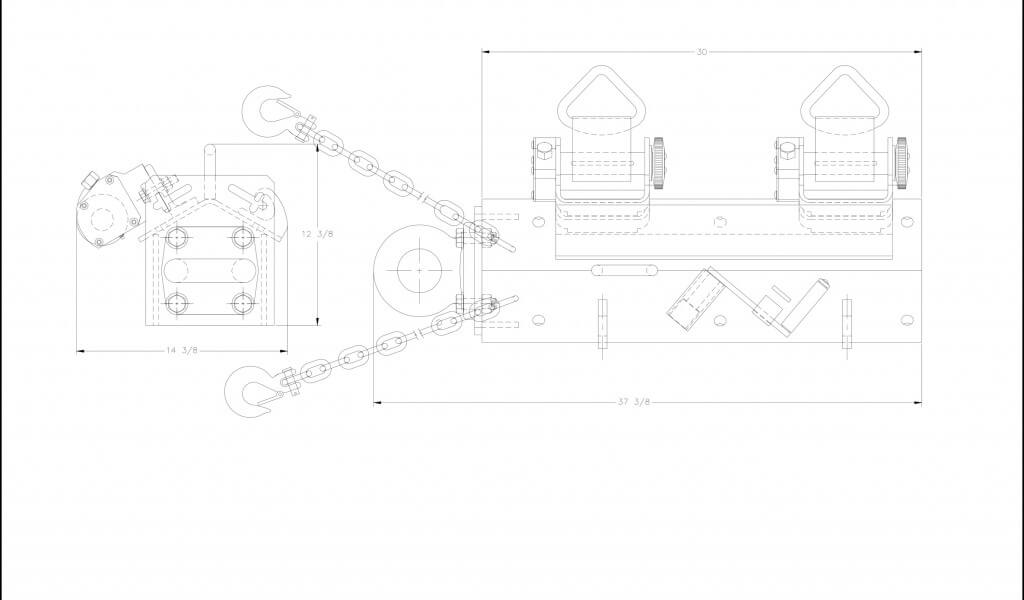

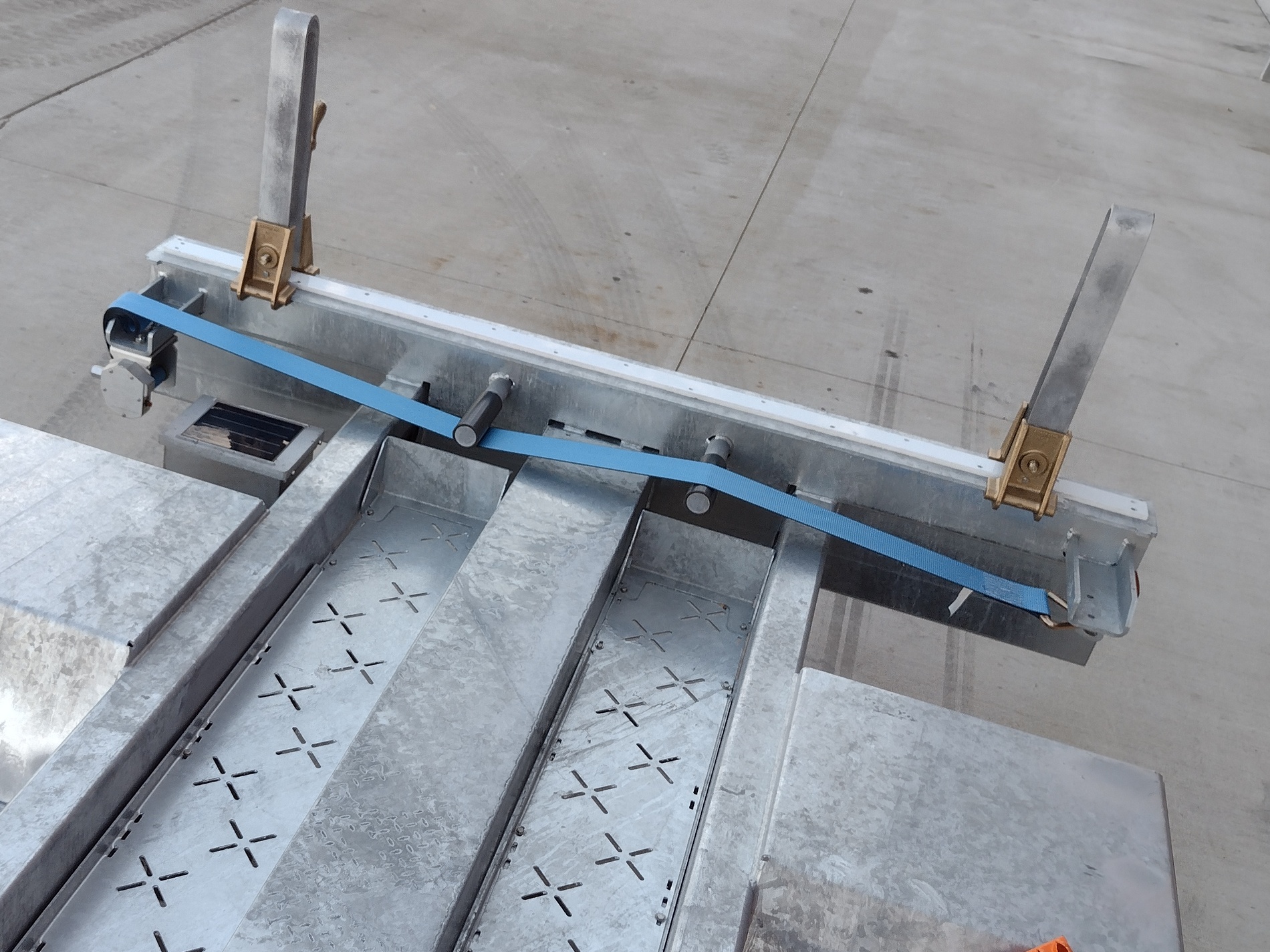

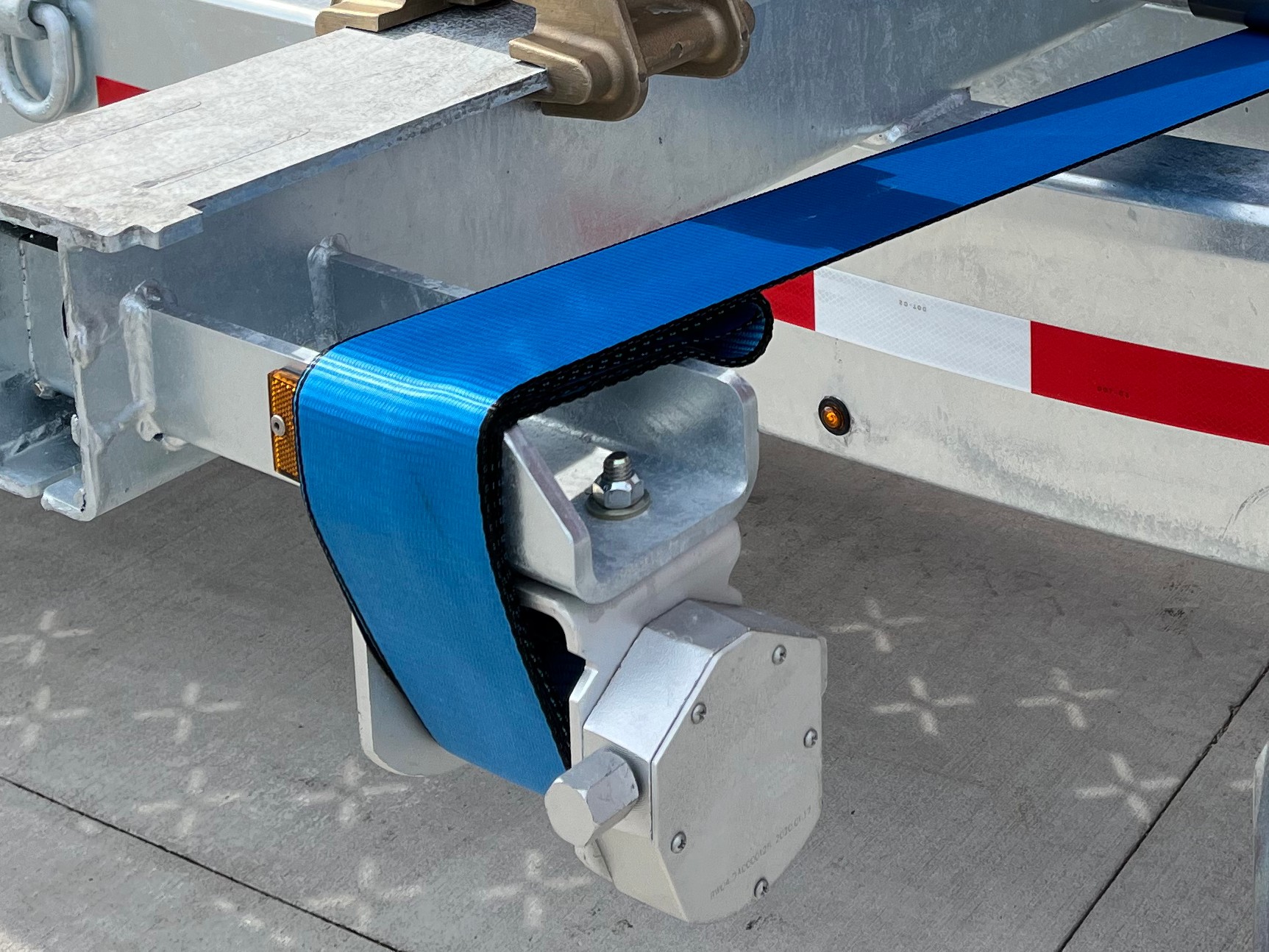

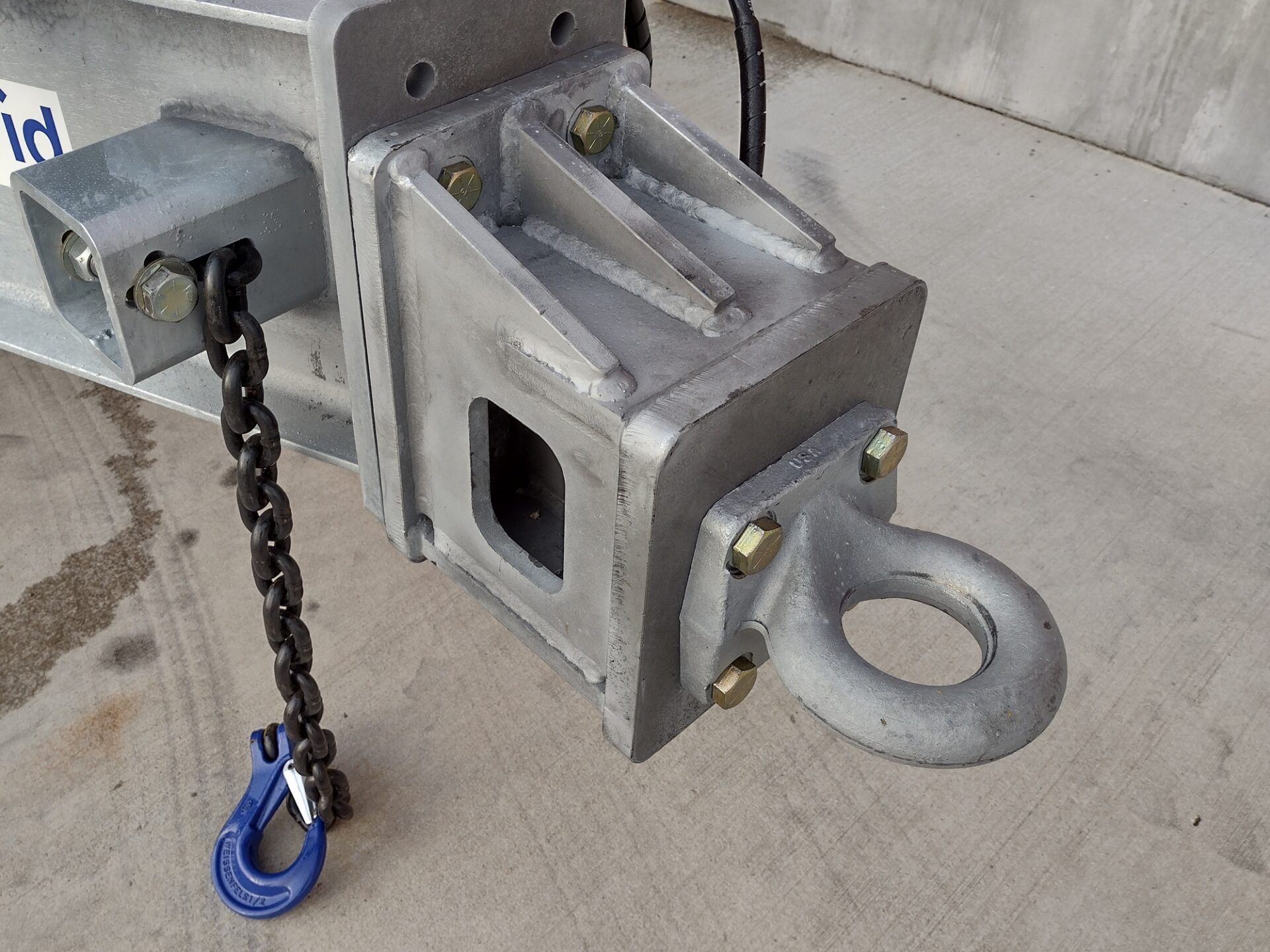

When you have a lot of work to do, a combination trailer saves you time. The Model 1521-PRC offers pole, reel and cargo capacity without compromises. Work with us to configure the right design including tensioning and retriever options, custom cargo space and special pole loads. We have the experience and expertise to manufacture the trailer that matches your work.

Click here to view similar equipment.

Capacity: 11700#

GVWR: 16450#

Retracted: 23"L x 96"W

Extended: 32'L x 96"W

Benefits