Self-Loading Trailer

Model 1526

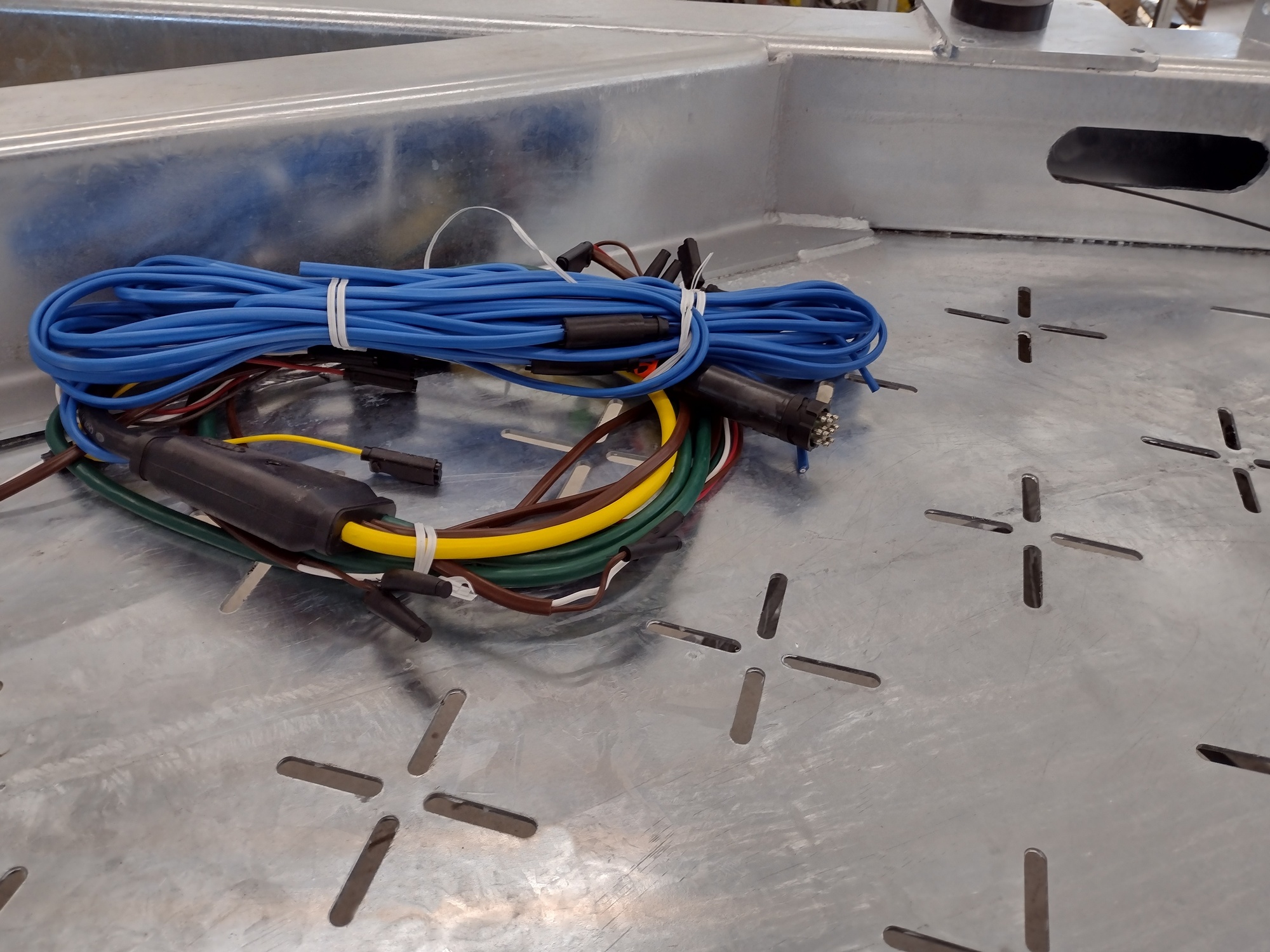

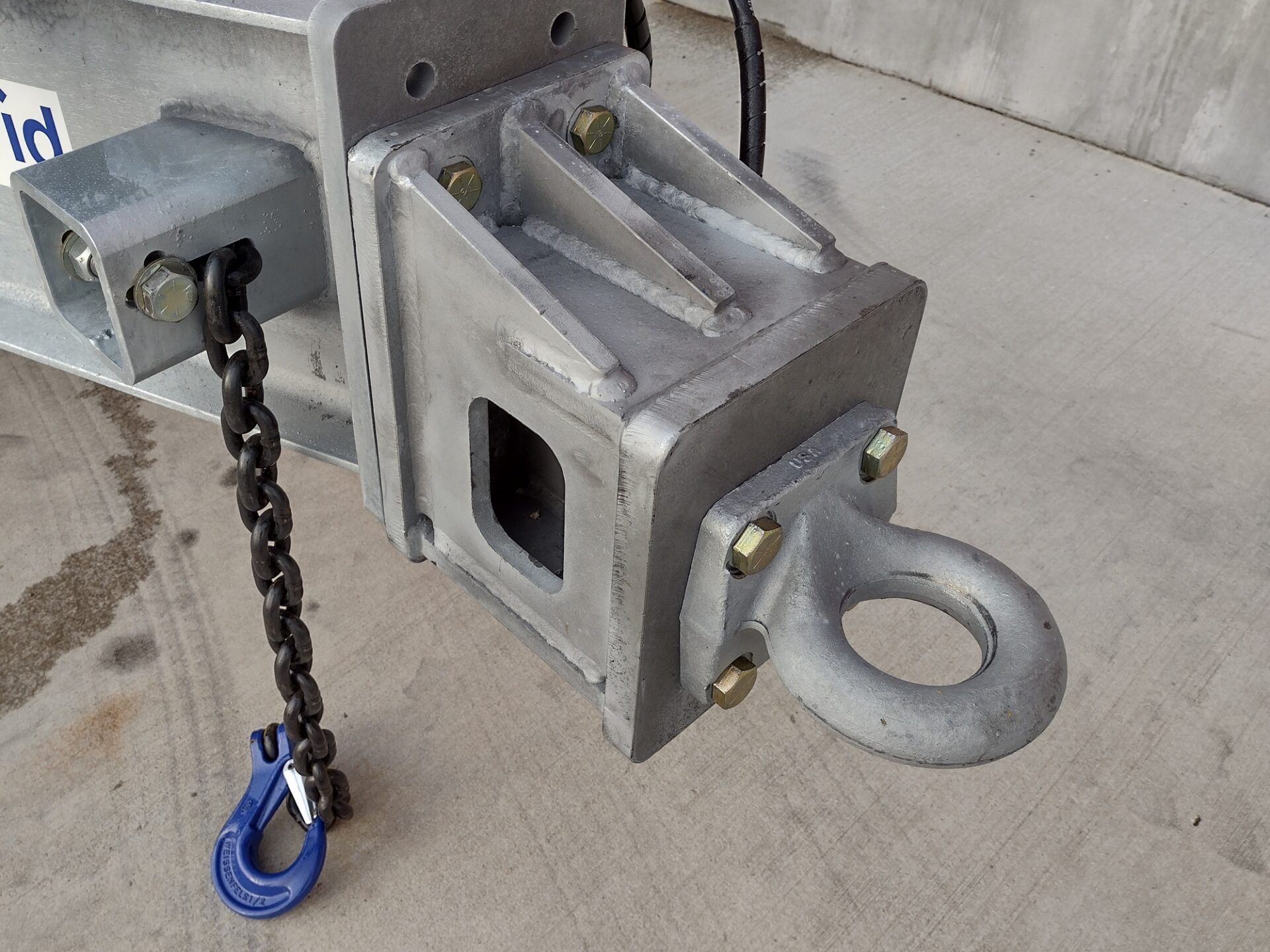

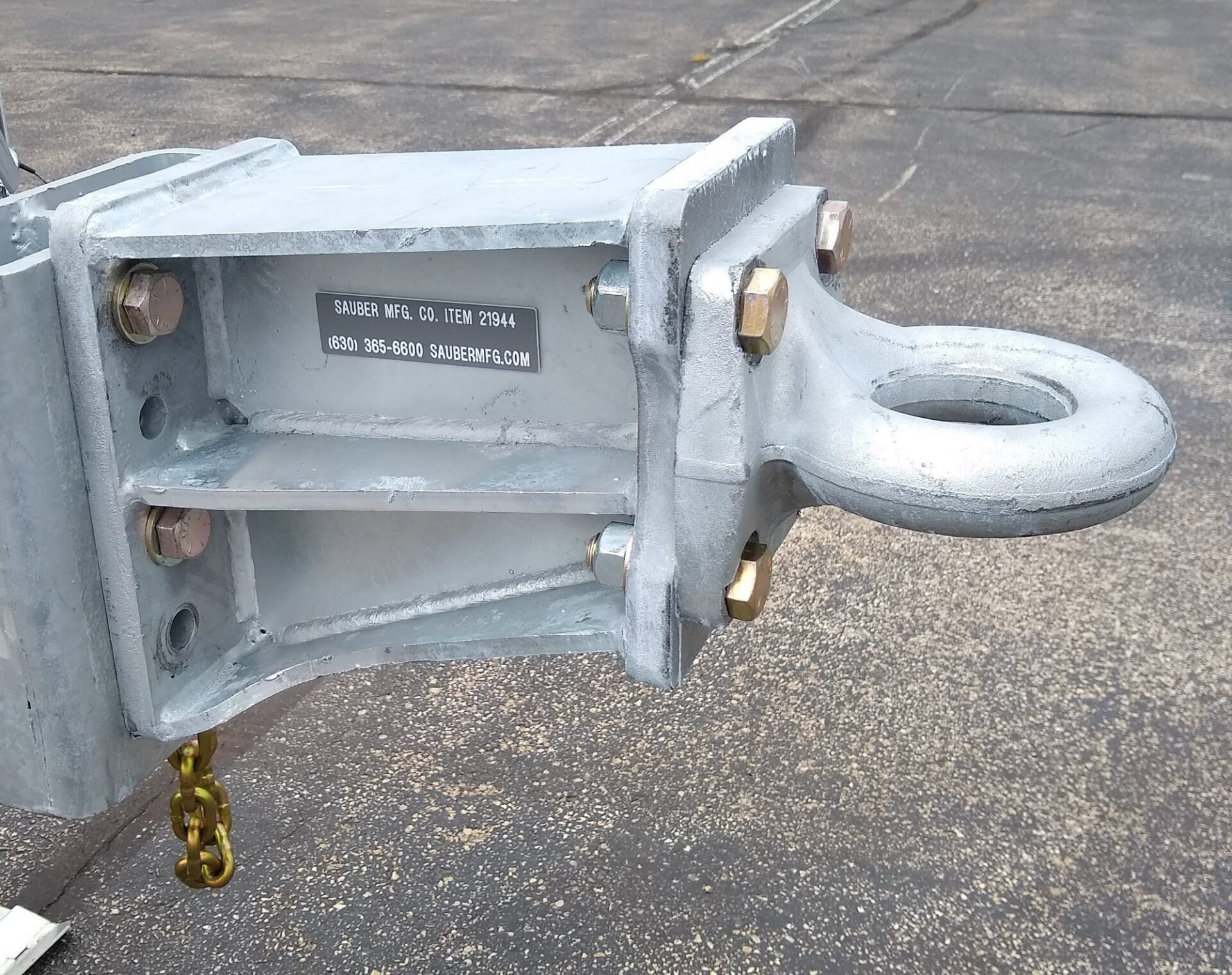

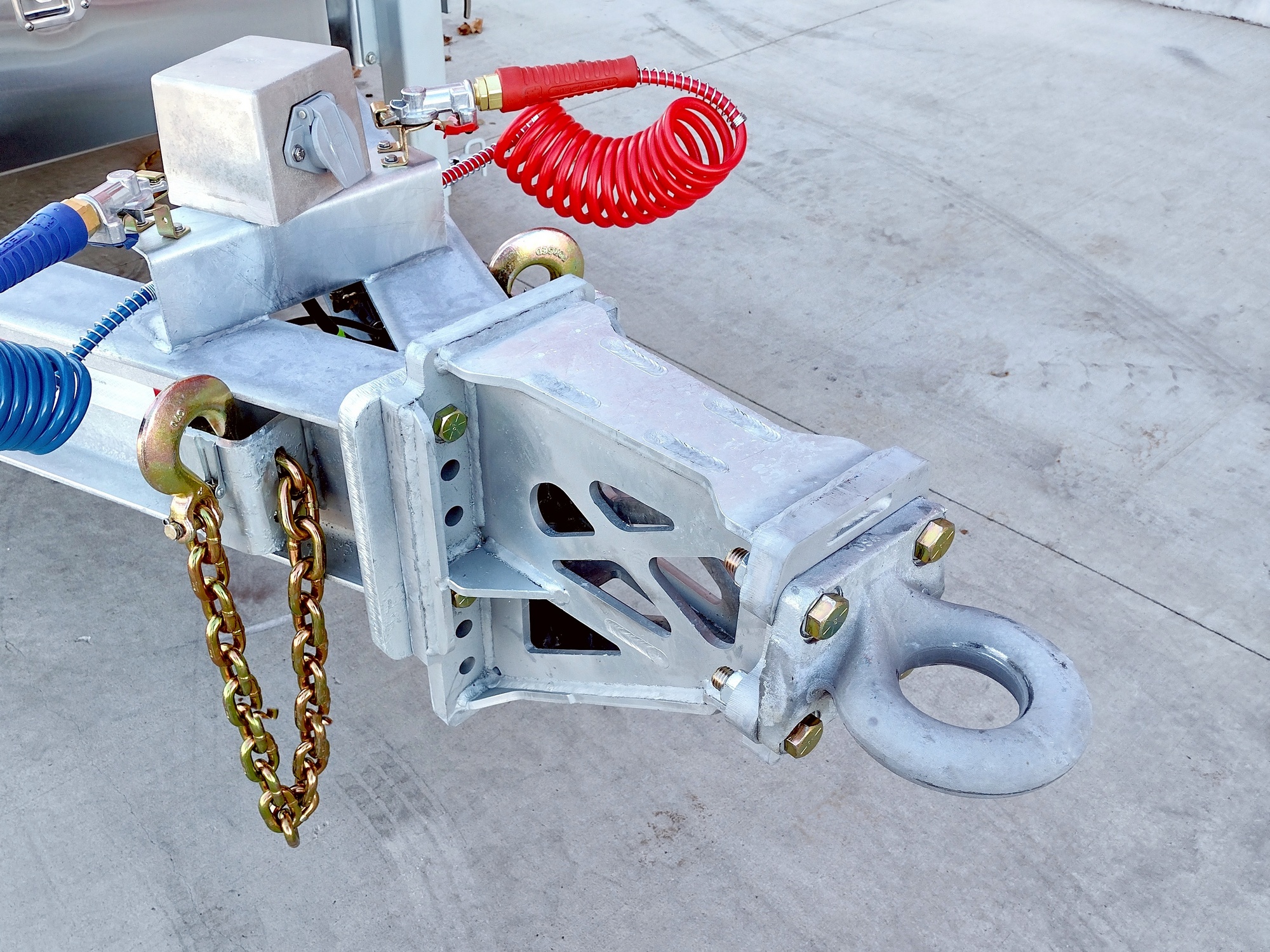

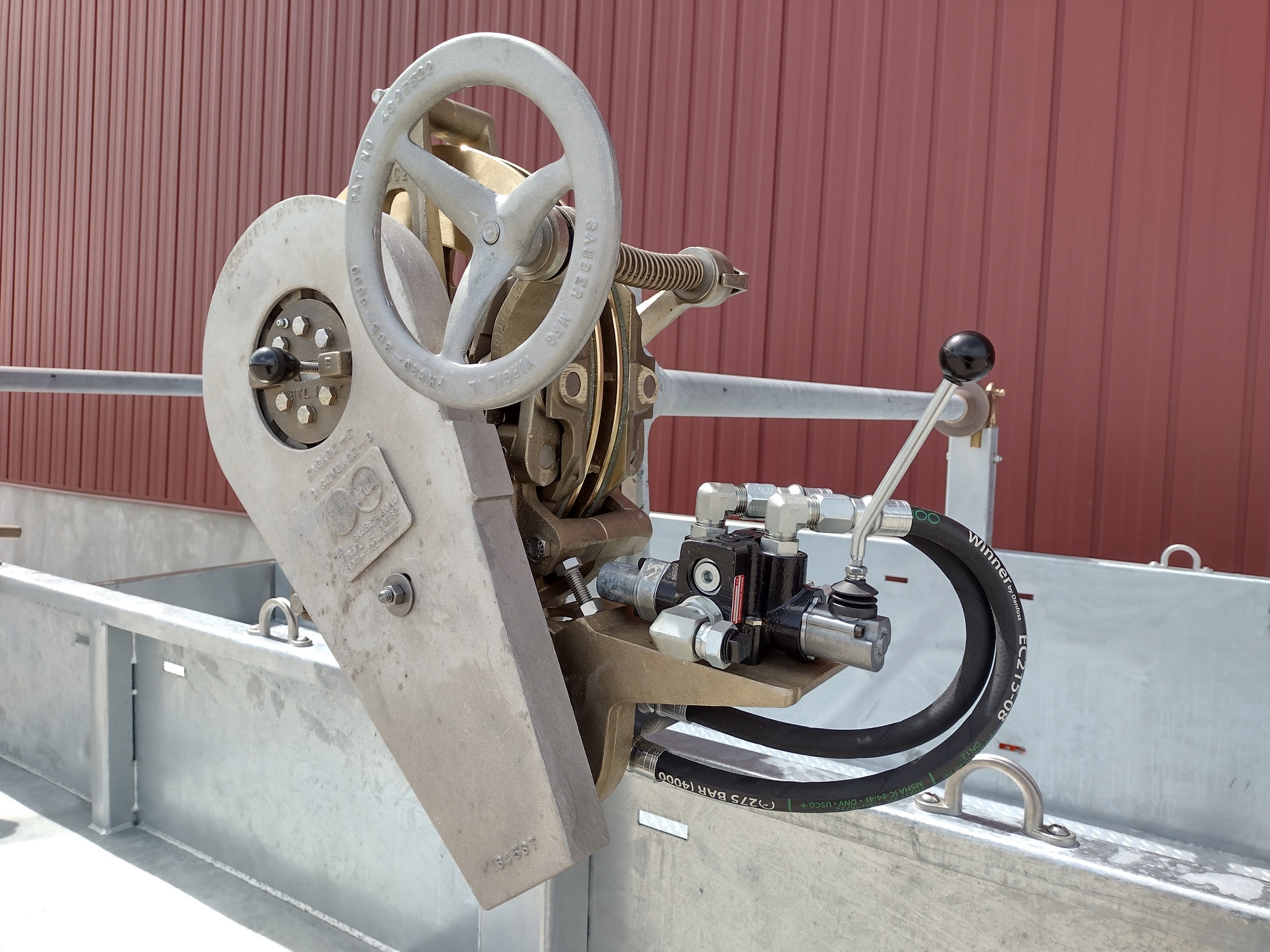

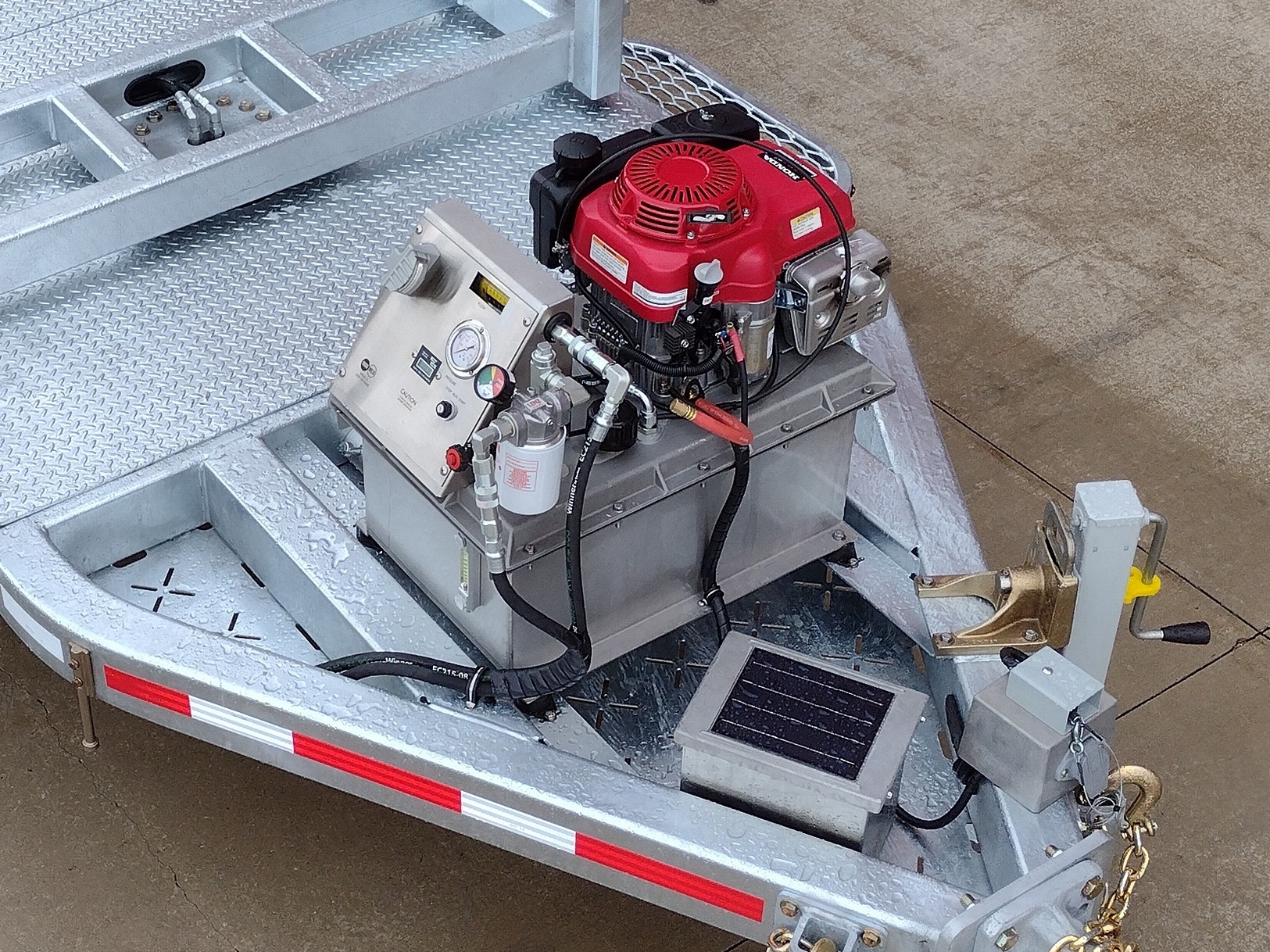

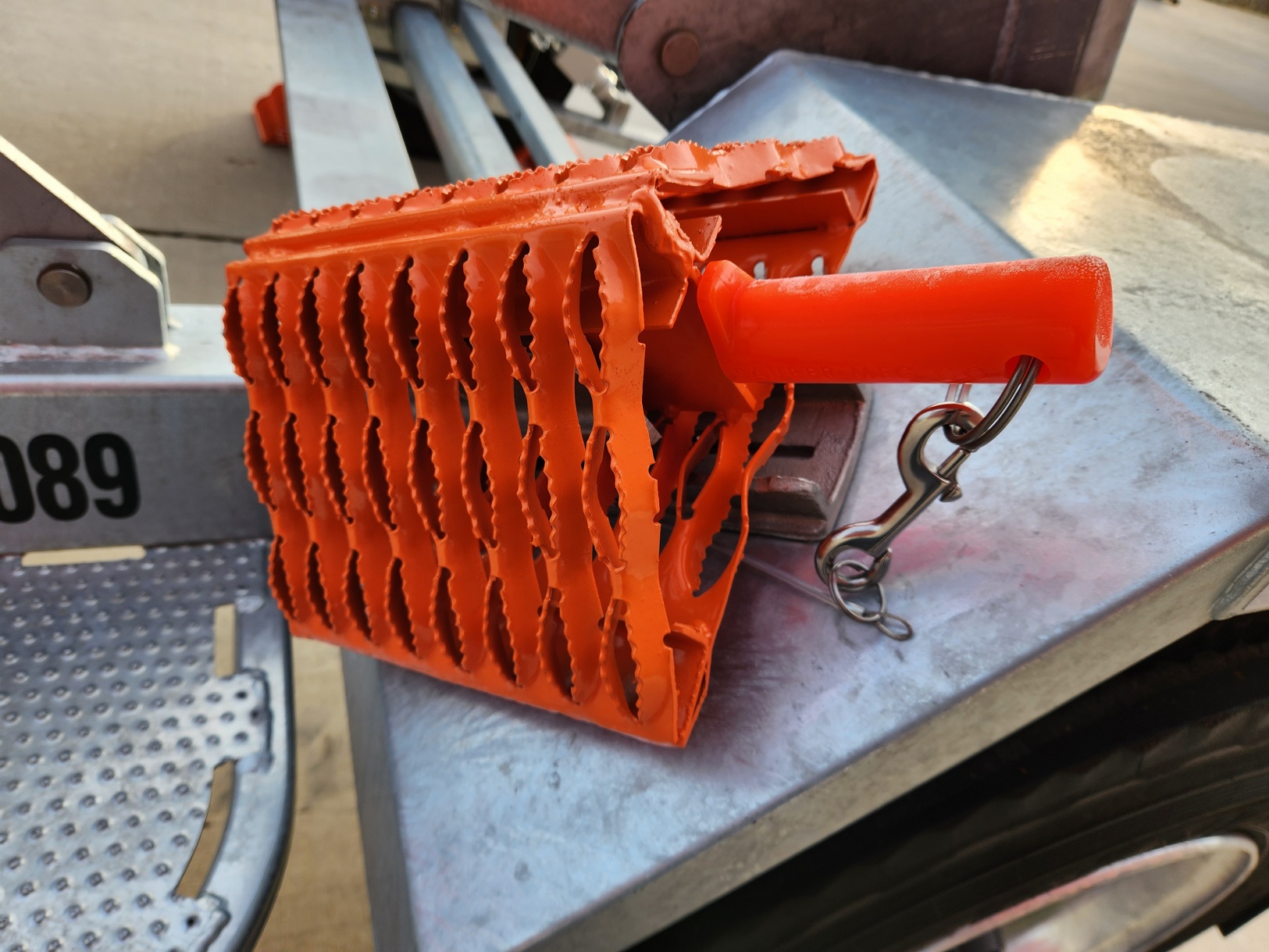

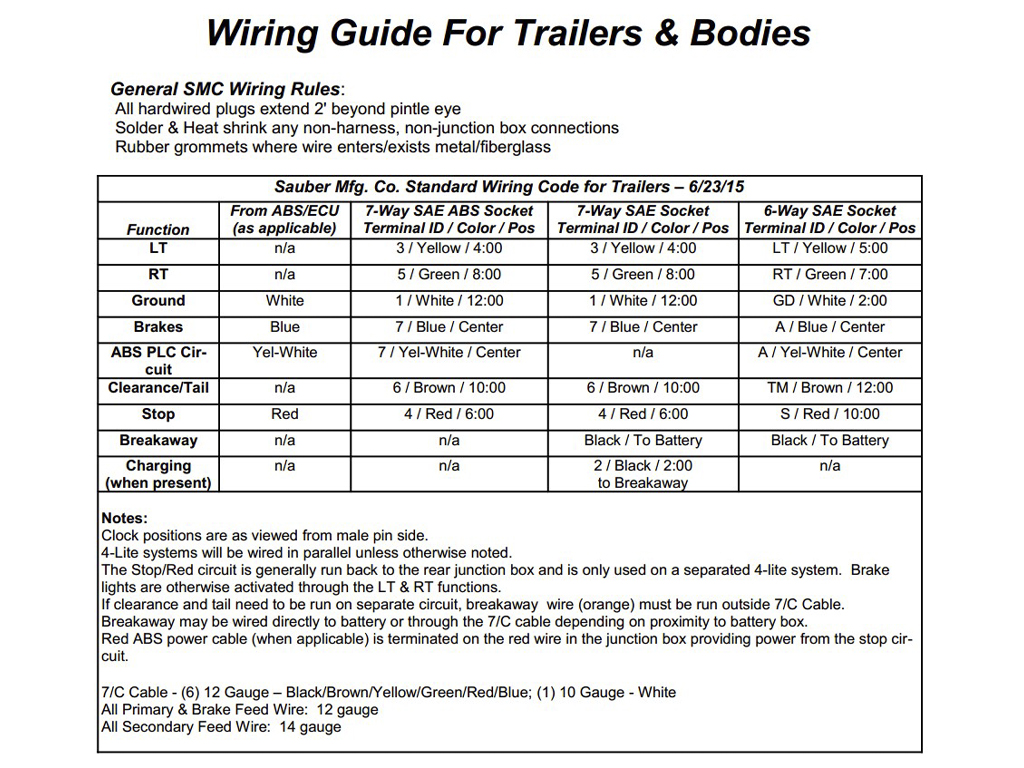

Boost your underground construction capabilities with this self-loading reel trailer that’s simple to load. With a beavertail loading method, you can be ready to transport heavy reels quickly. The flange drive brake and retriever are standard and avoid the heavy work of moving large cable by hand. The Model 1010 Series Power source is reliable with a vertical shaft, submerged pump and two stage filtration for reliability. And Sauber Mfg. Co.’s standard hot dipped galvanized bent tubing frame plus premium wiring ensure this solution will last for years.

Click Here to see other trailers in this category.

Capacity: 11200# Trailer; 8000# Reel Loading

GVWR: 15550#

Reel Size: 48-96"Dia x 64"W

Dimensions: 14'L x 96"W