Four Reel Trailer

Model 1542

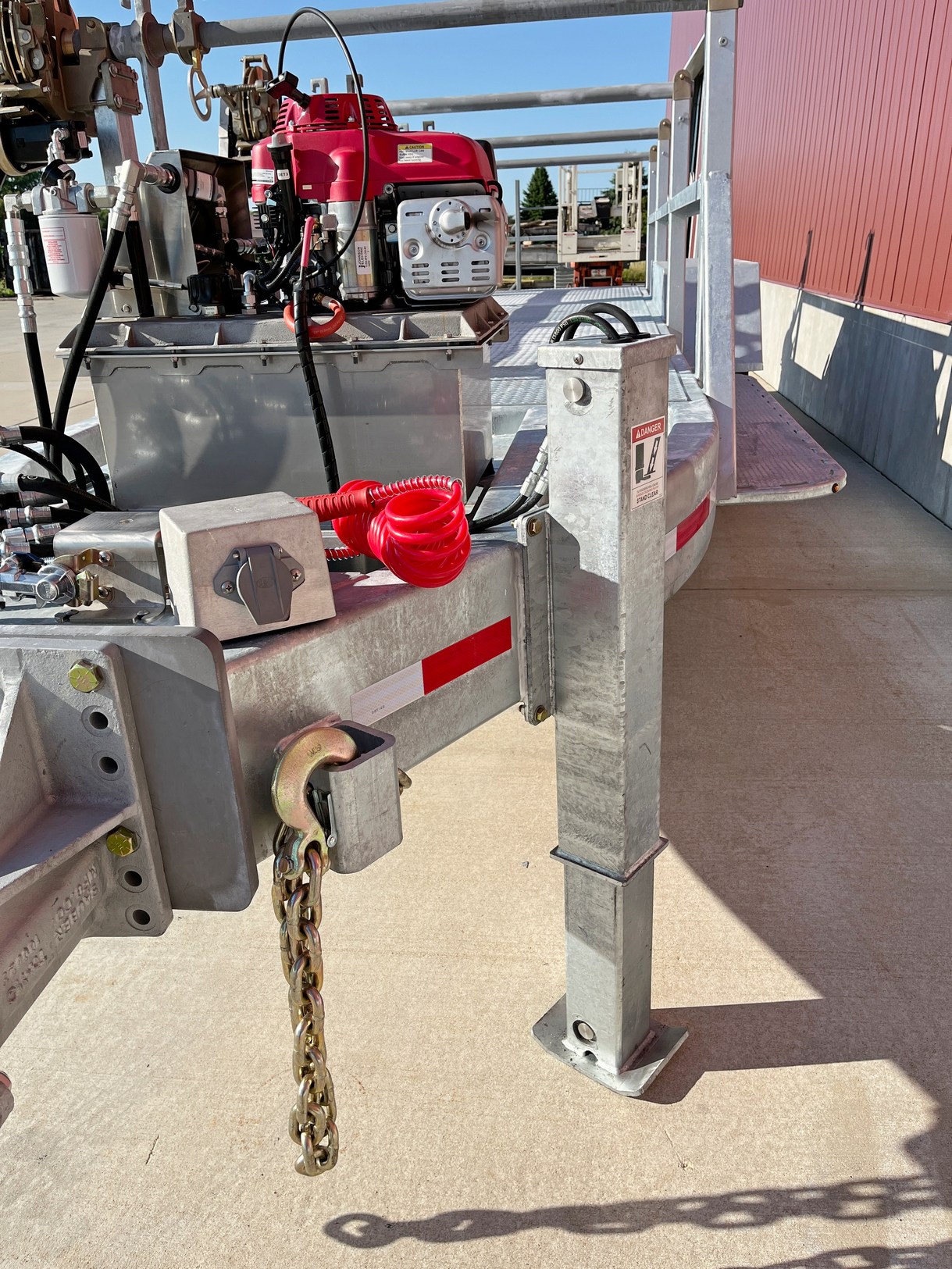

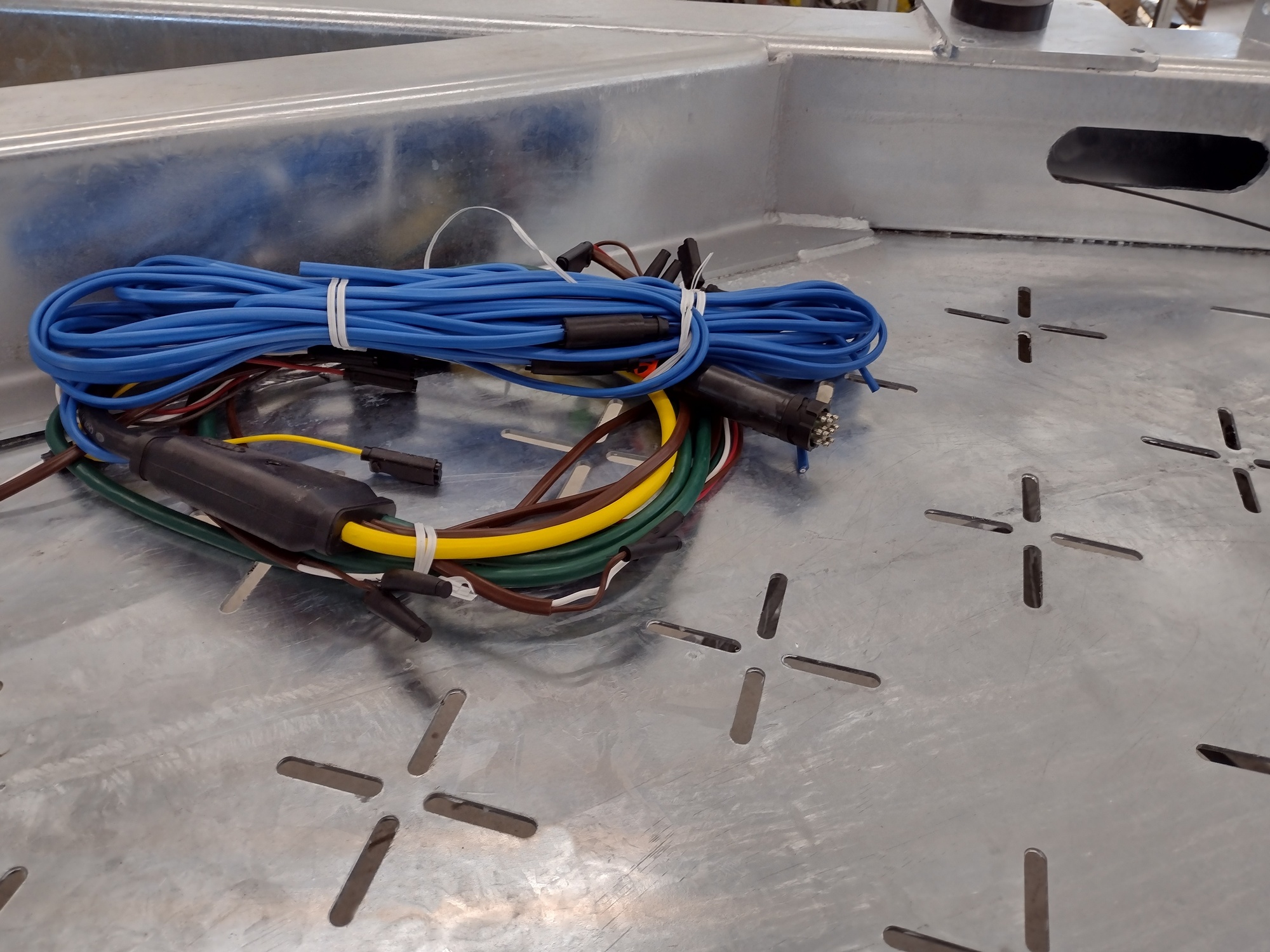

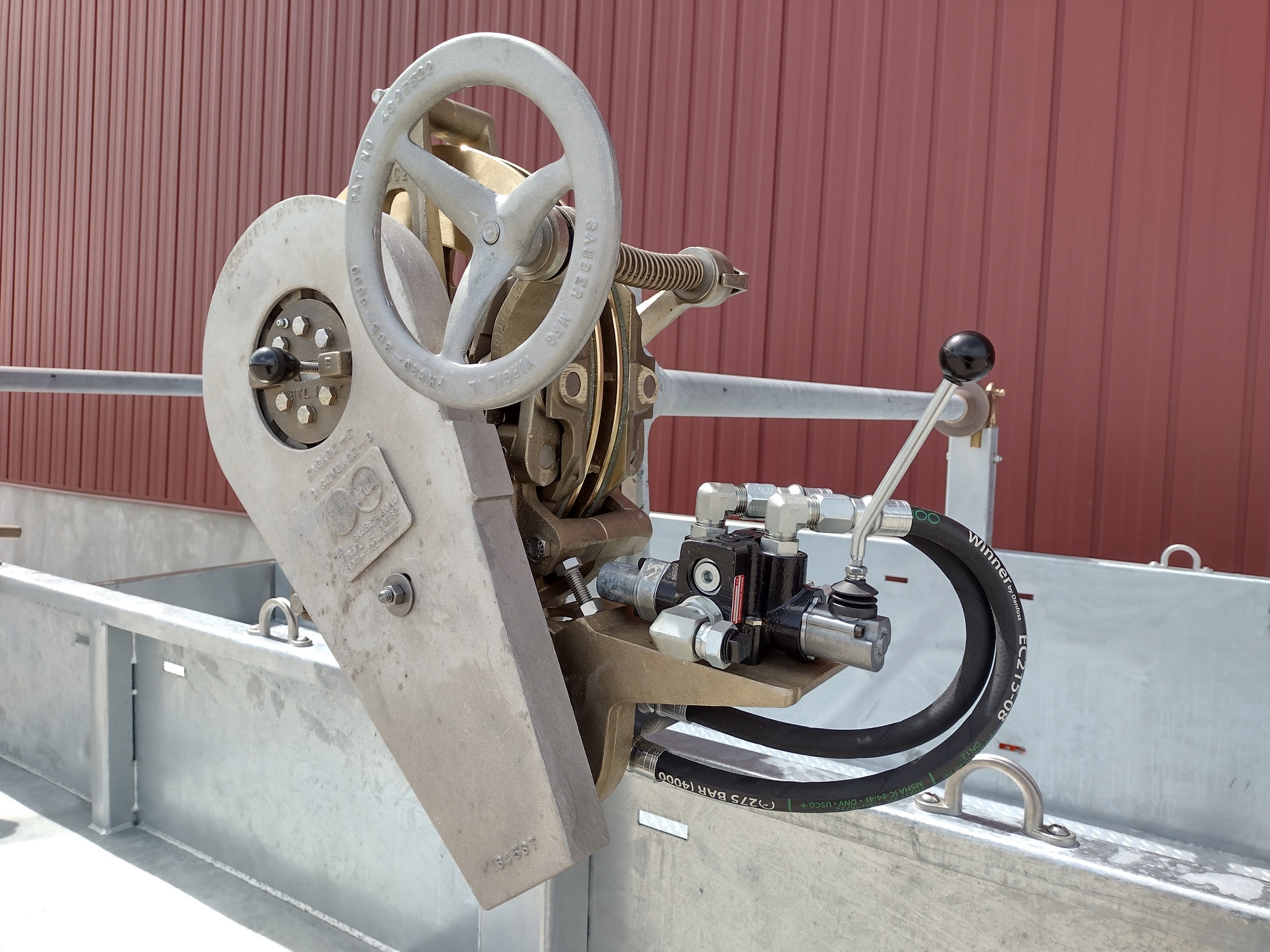

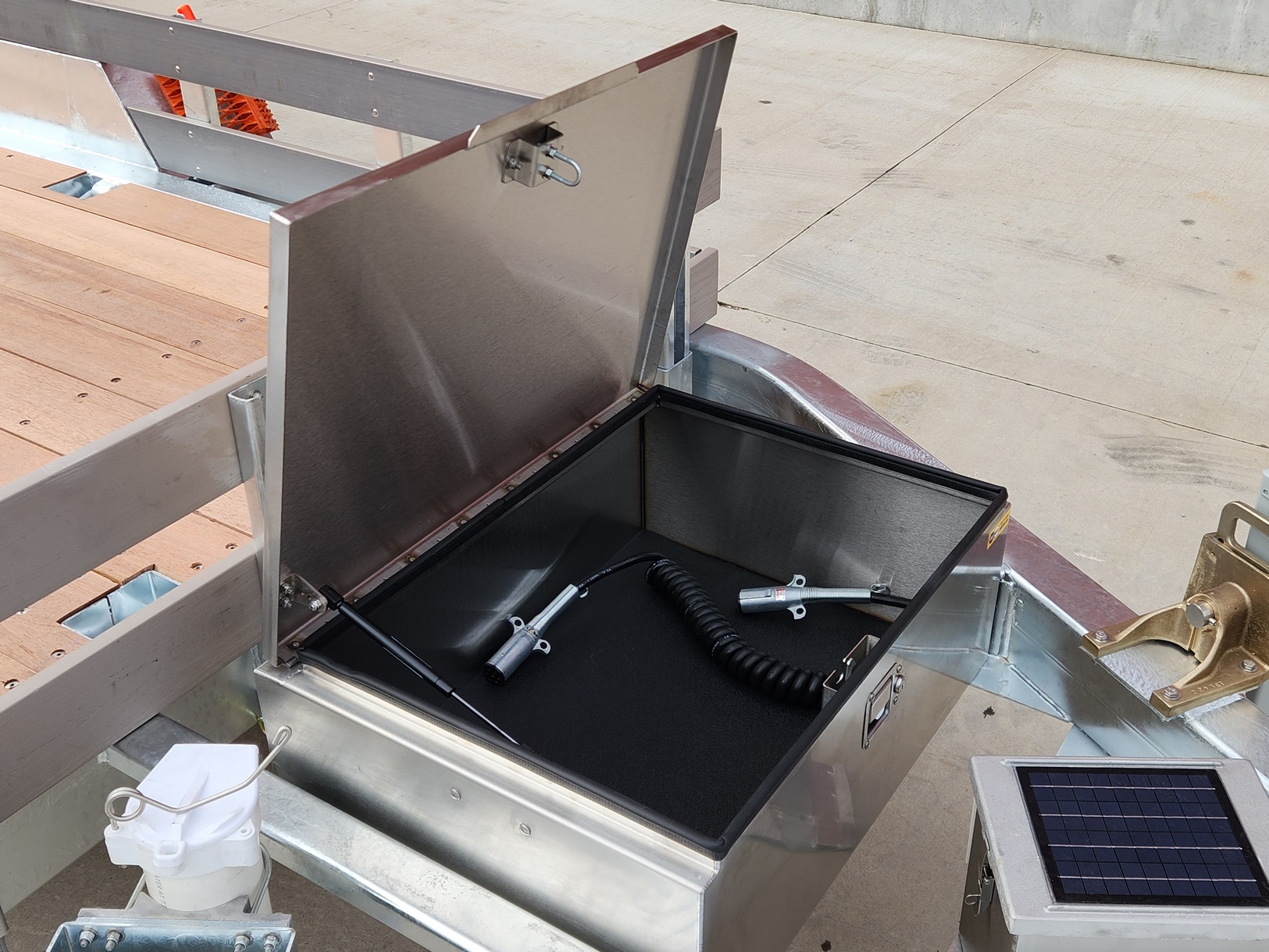

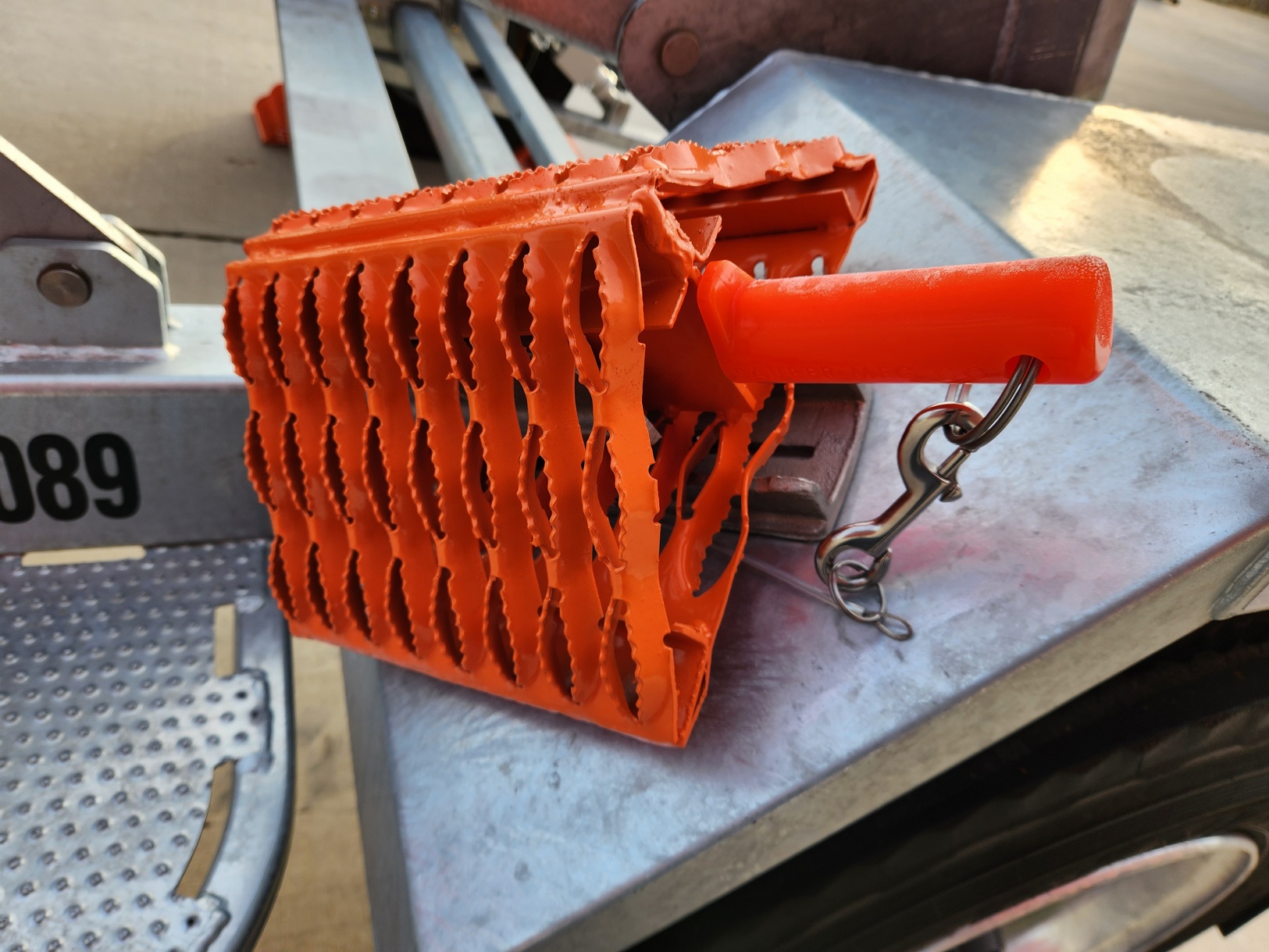

Your crews are more effective when completing three phase line construction with all the reels are on one trailer. Specify the trailer capacity with us before we build so you optimize your equipment's size and cost. Optional components such as onboard hydraulic power with “ready to go” hydraulics or conductor guides are built to work well and last a long time, as you would expect from Sauber Mfg. Co.

Click here to see other models similar to the Model 1542 Four Reel Turret Trailer.

Capacity: 26400#

GVWR: 35250#

Reel Size: 72"Dia x 54"W

Dimensions: 28'L x 101"W