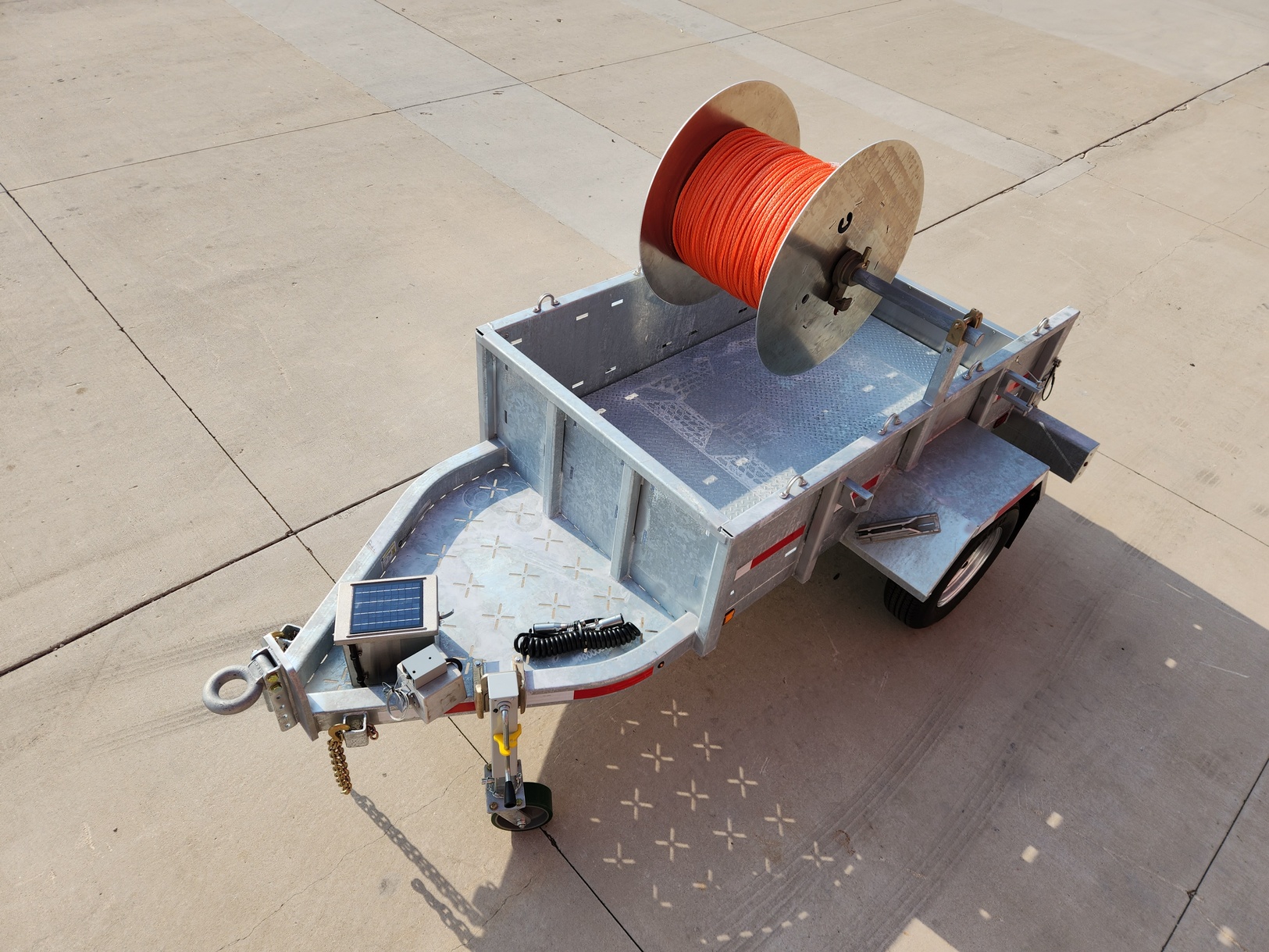

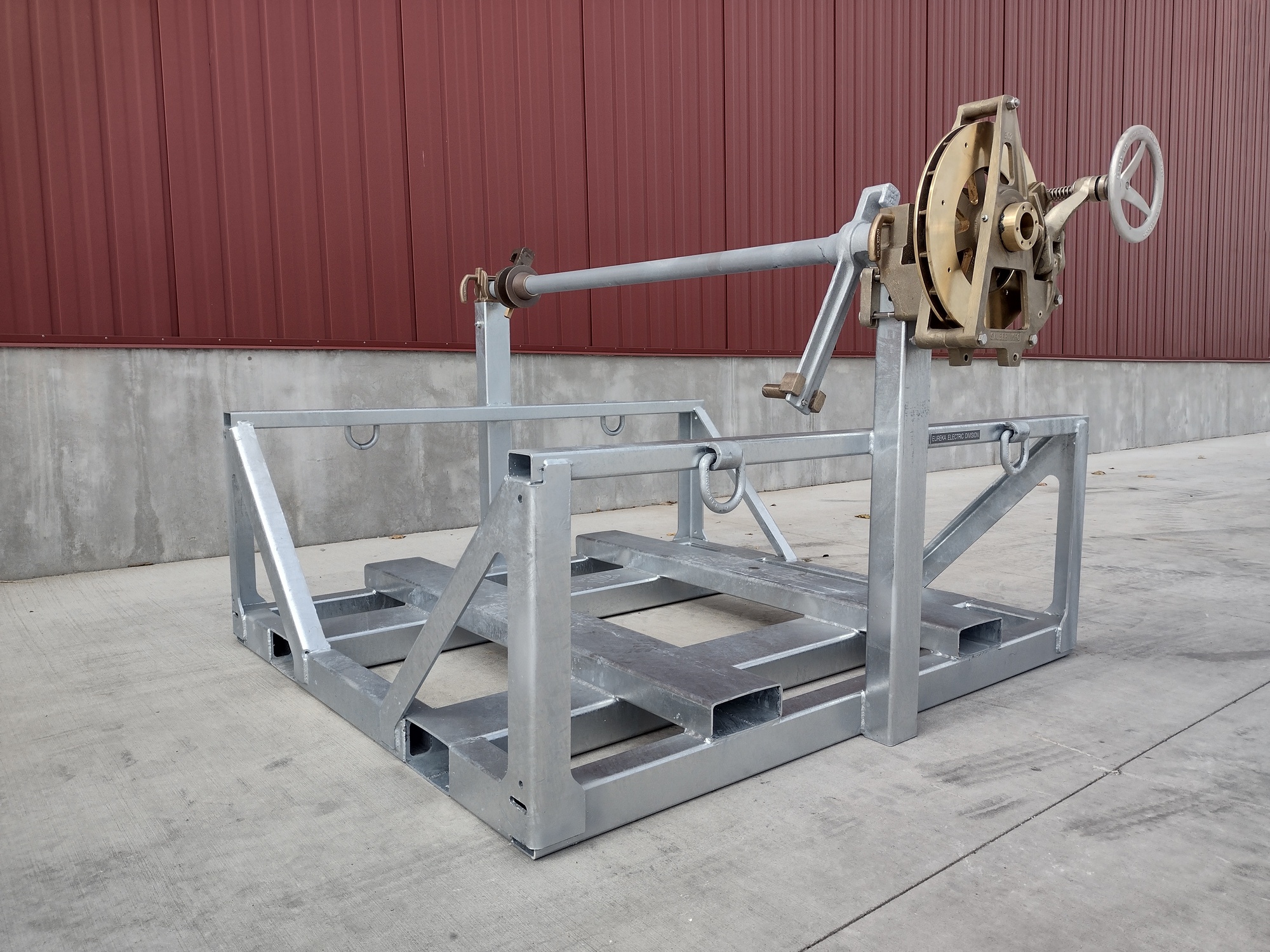

Reel & Cargo Trailer

Model 1550-A

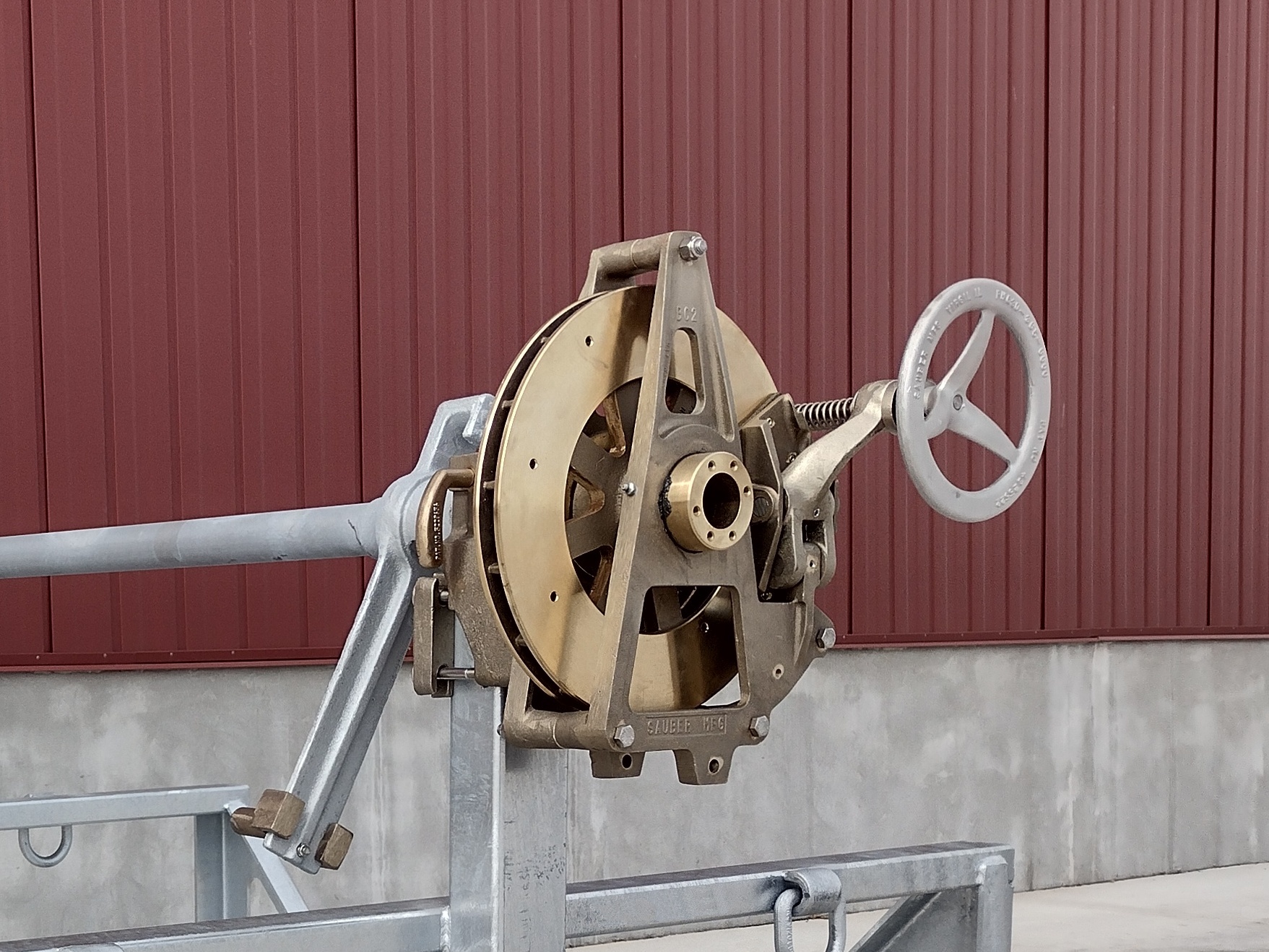

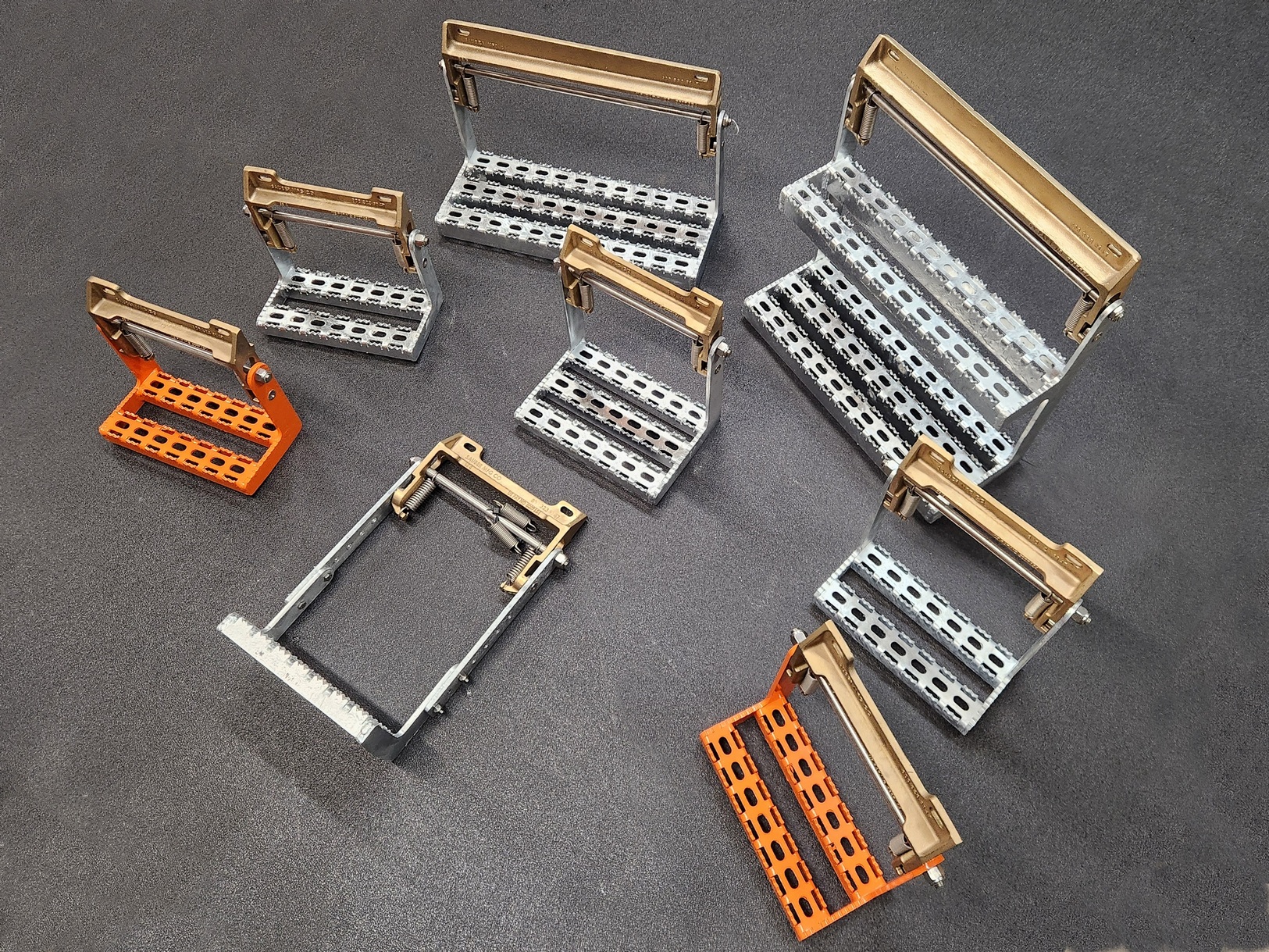

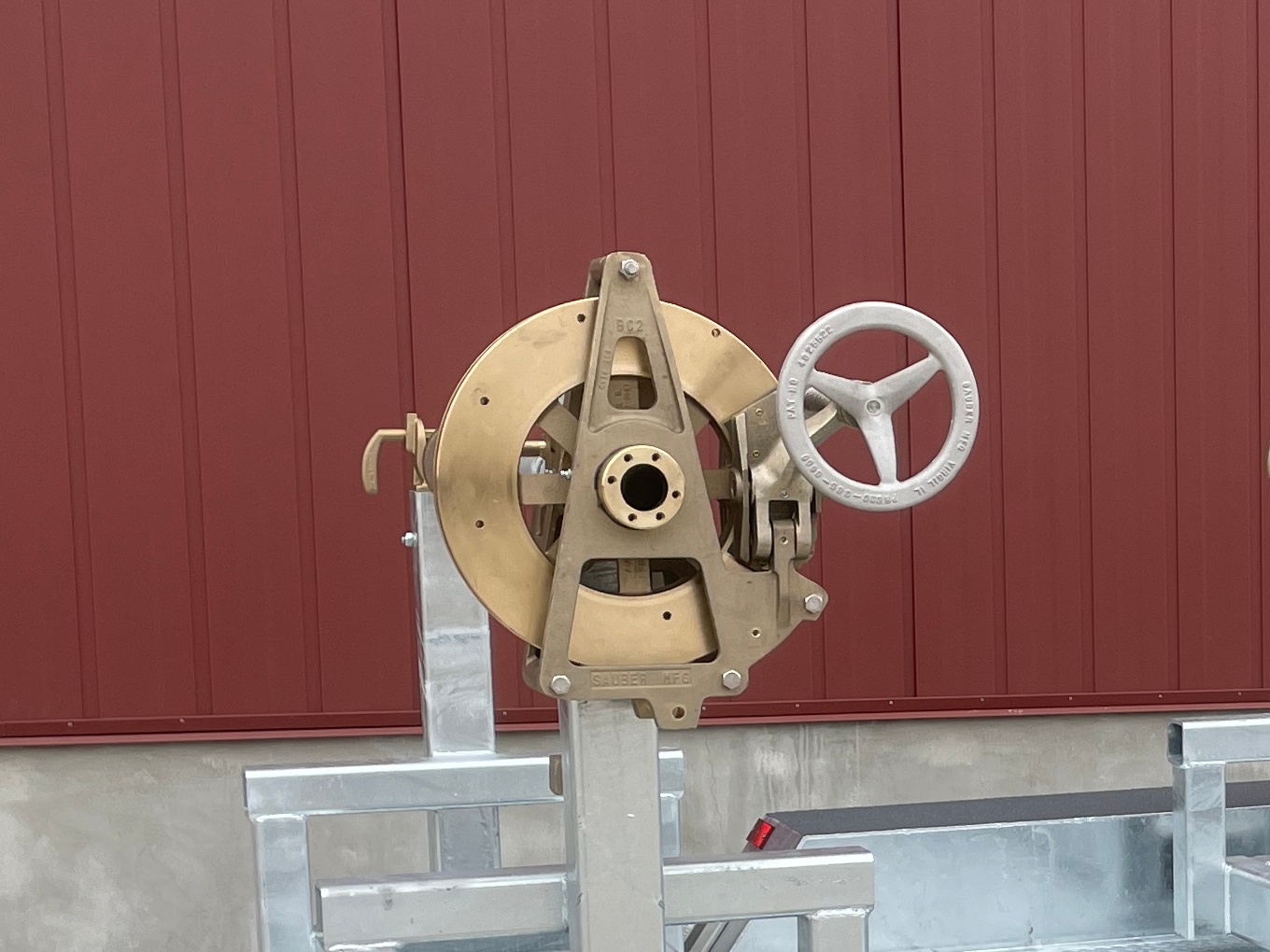

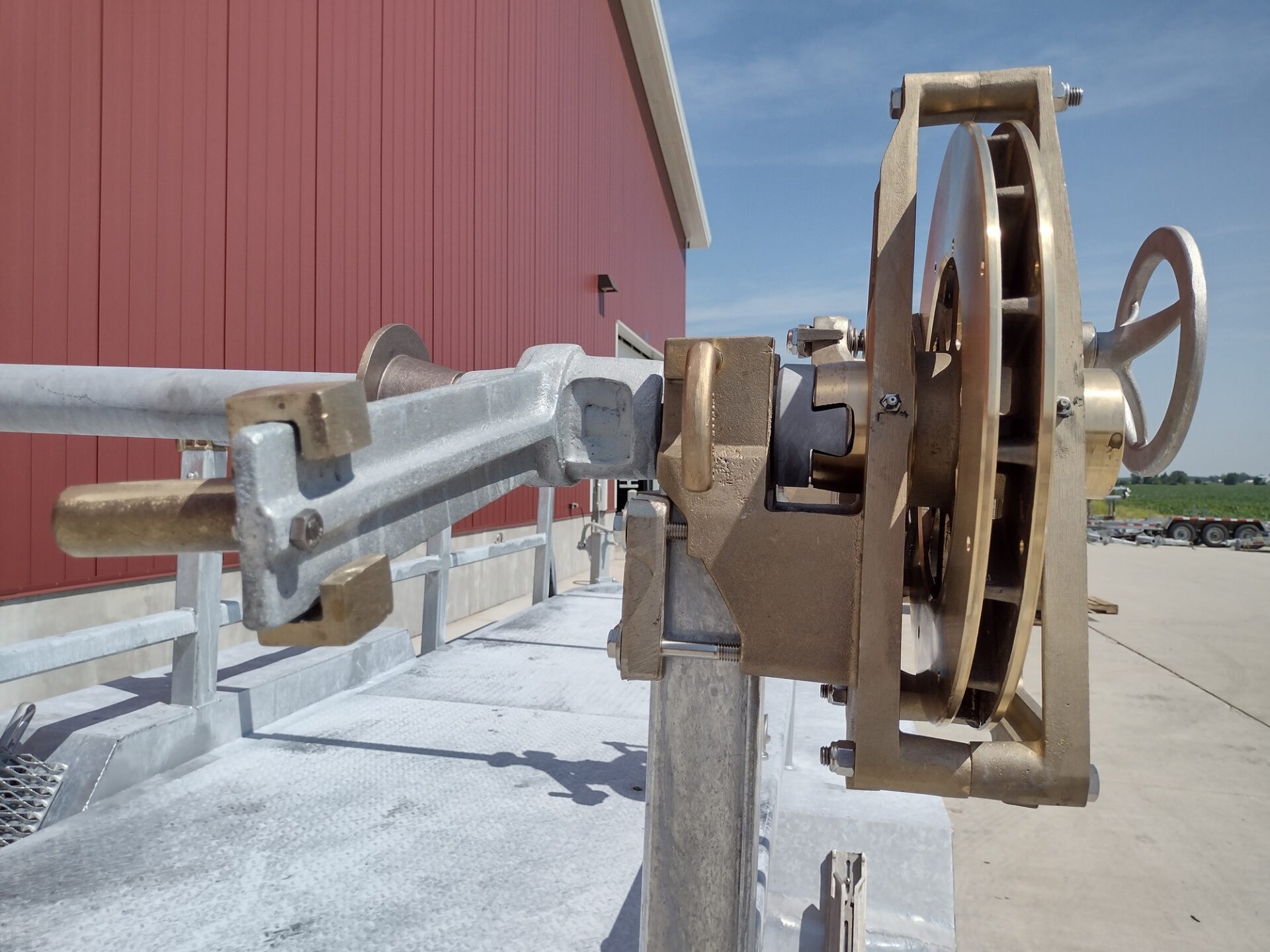

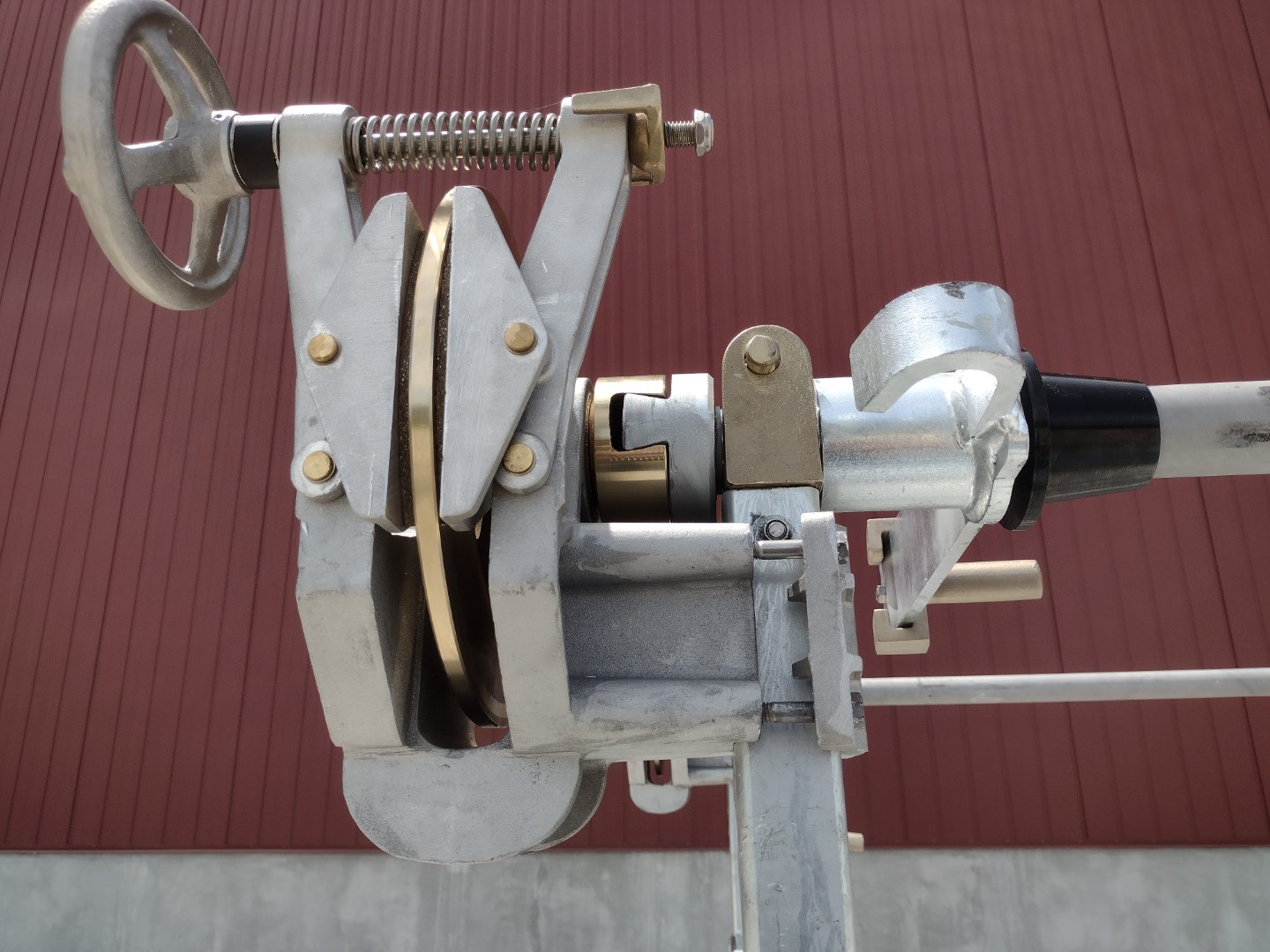

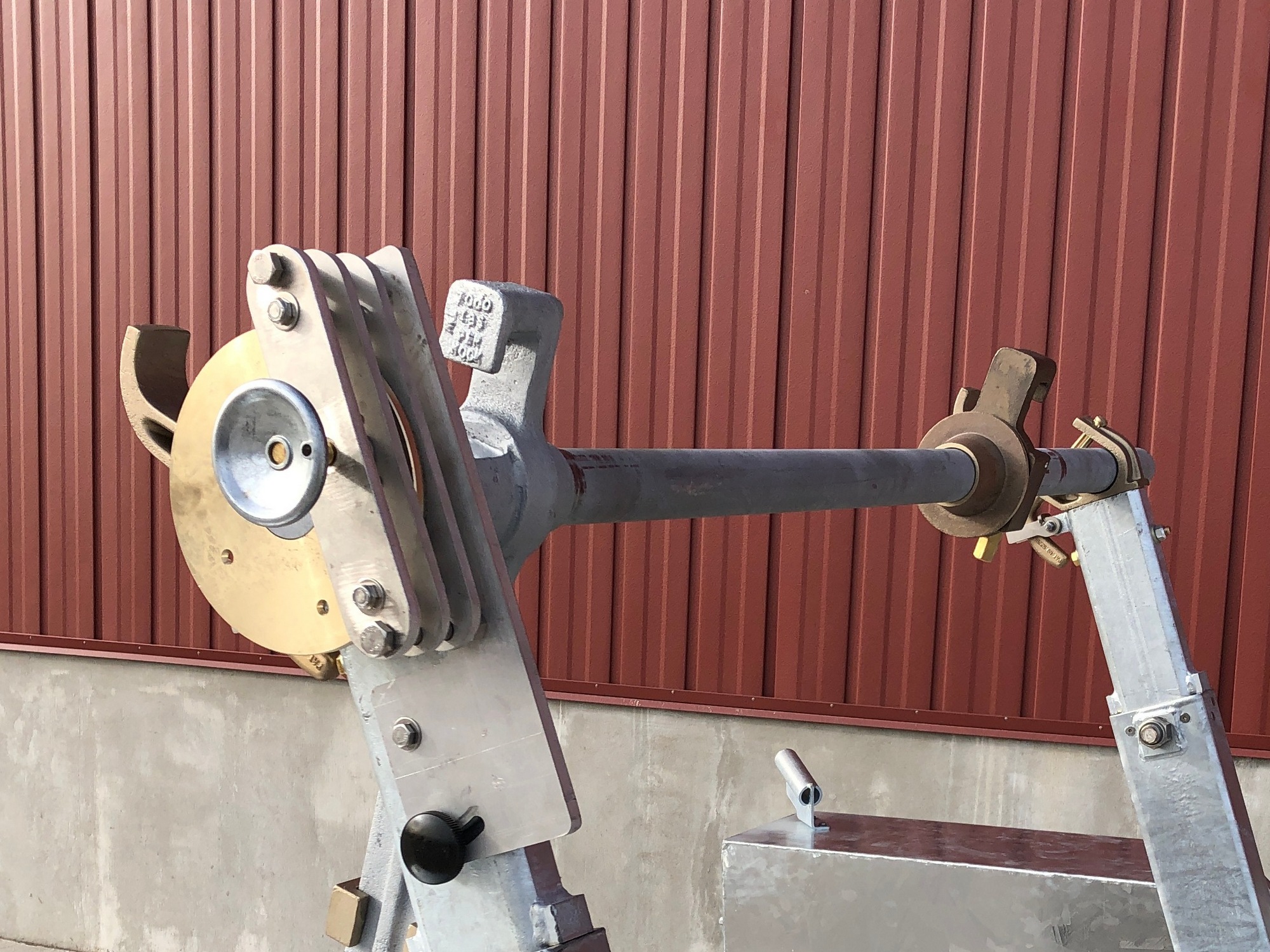

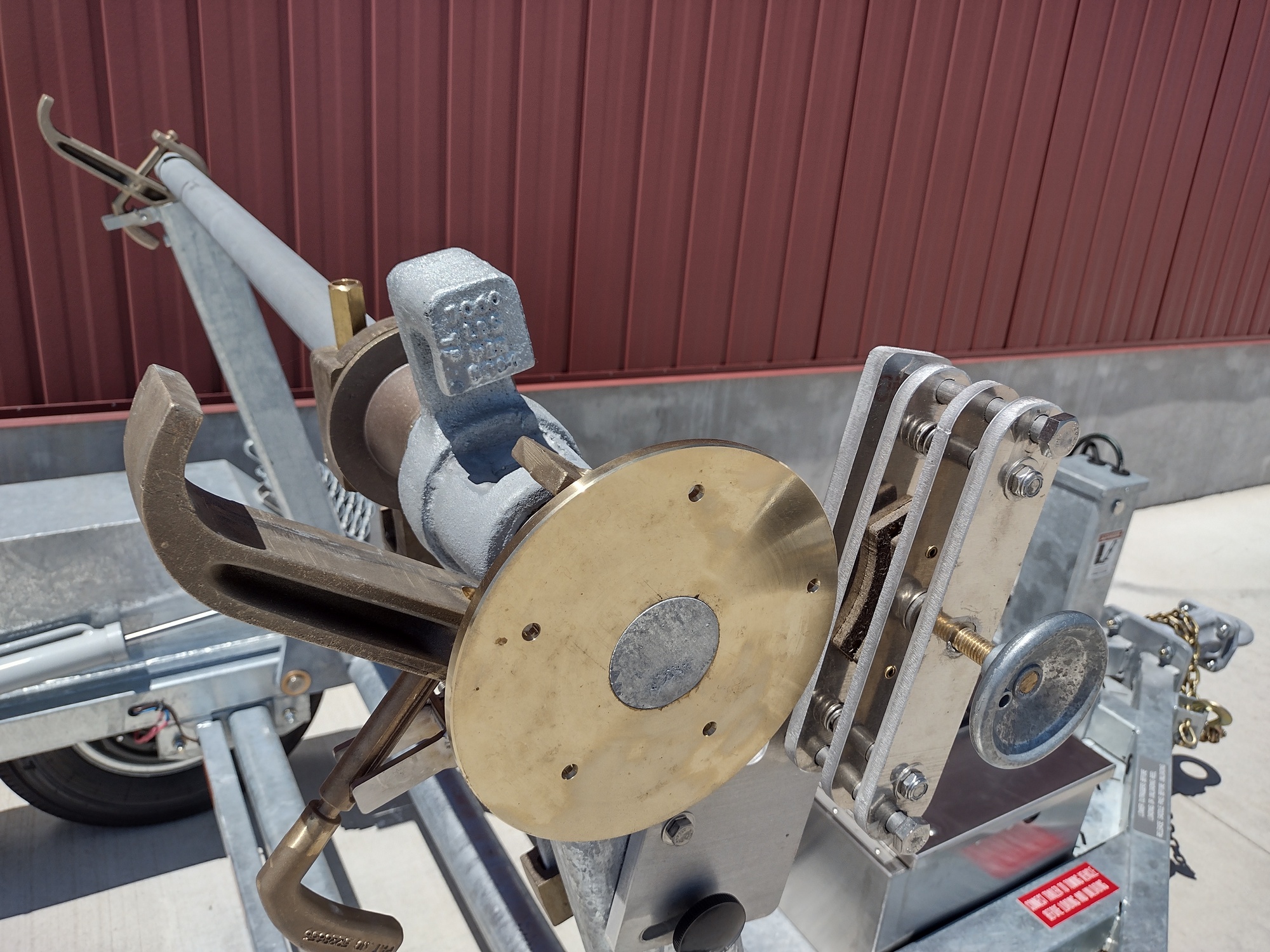

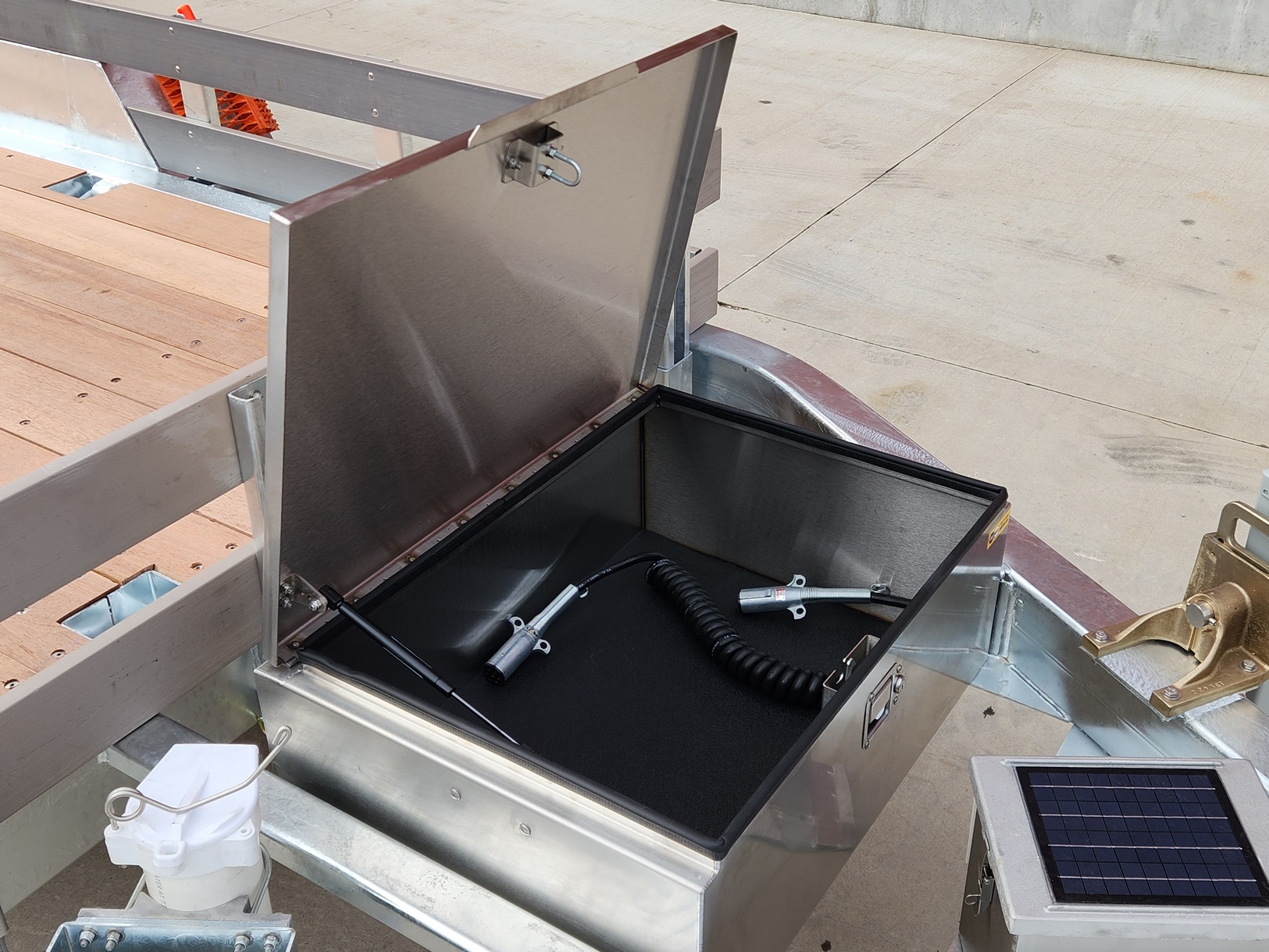

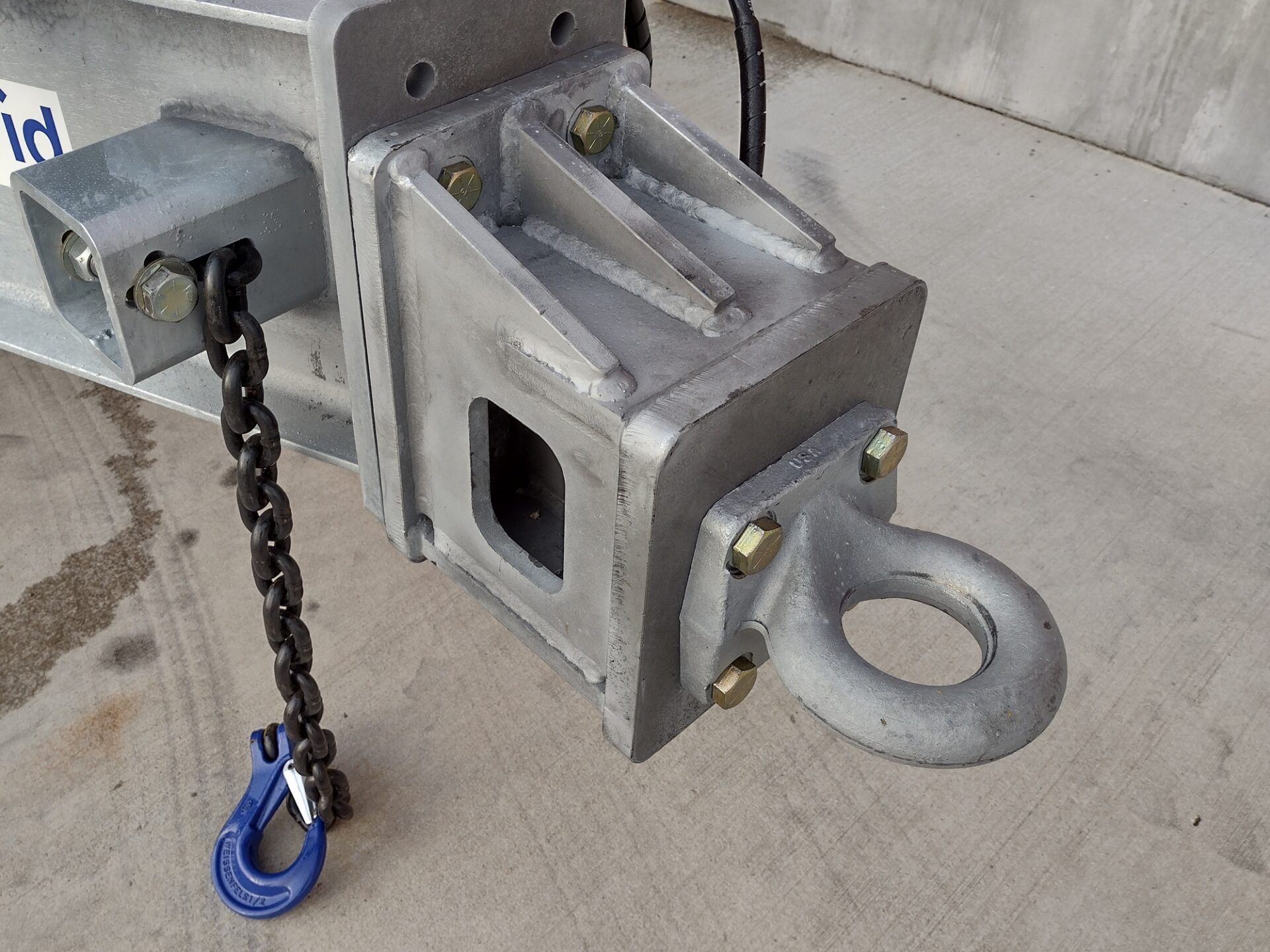

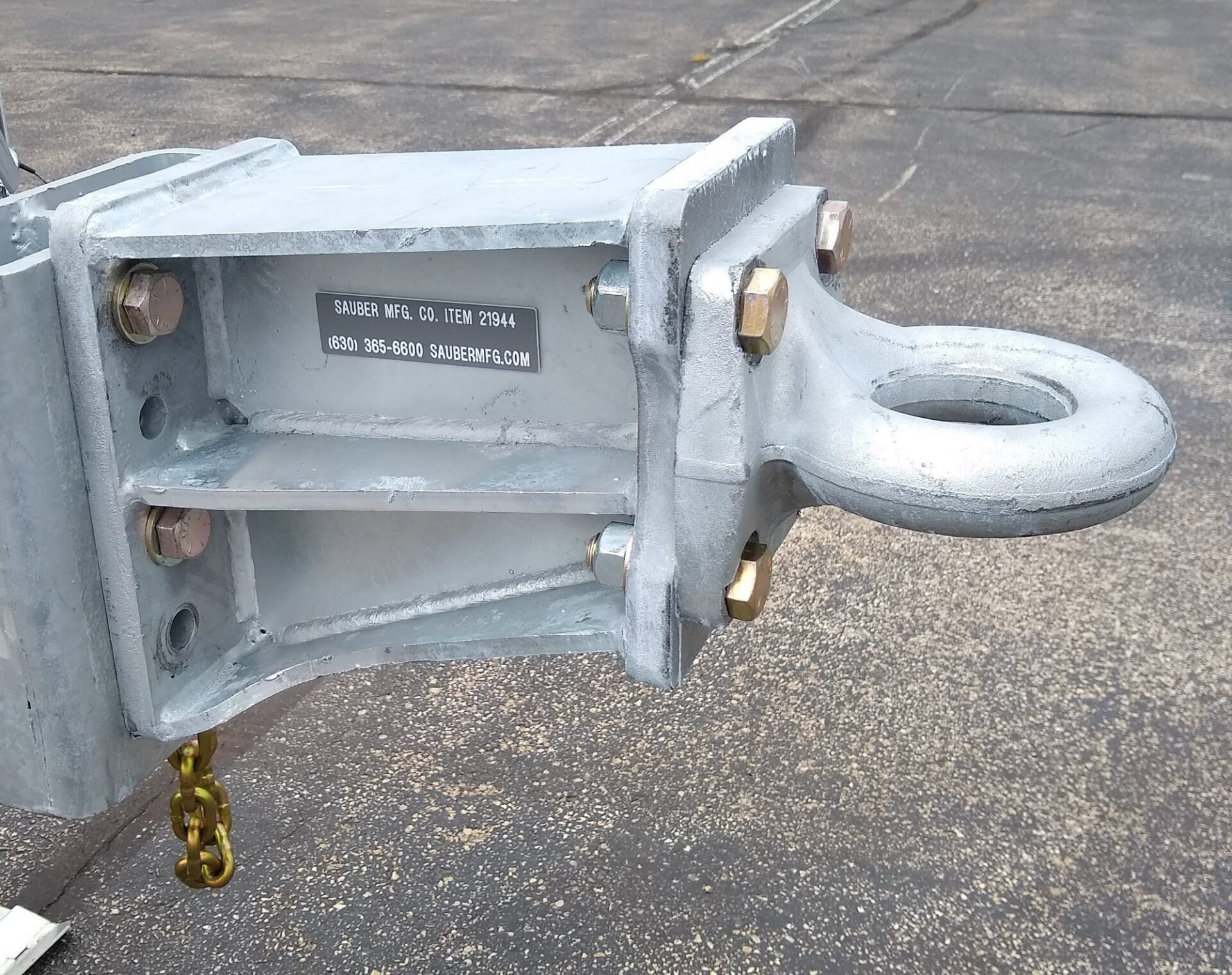

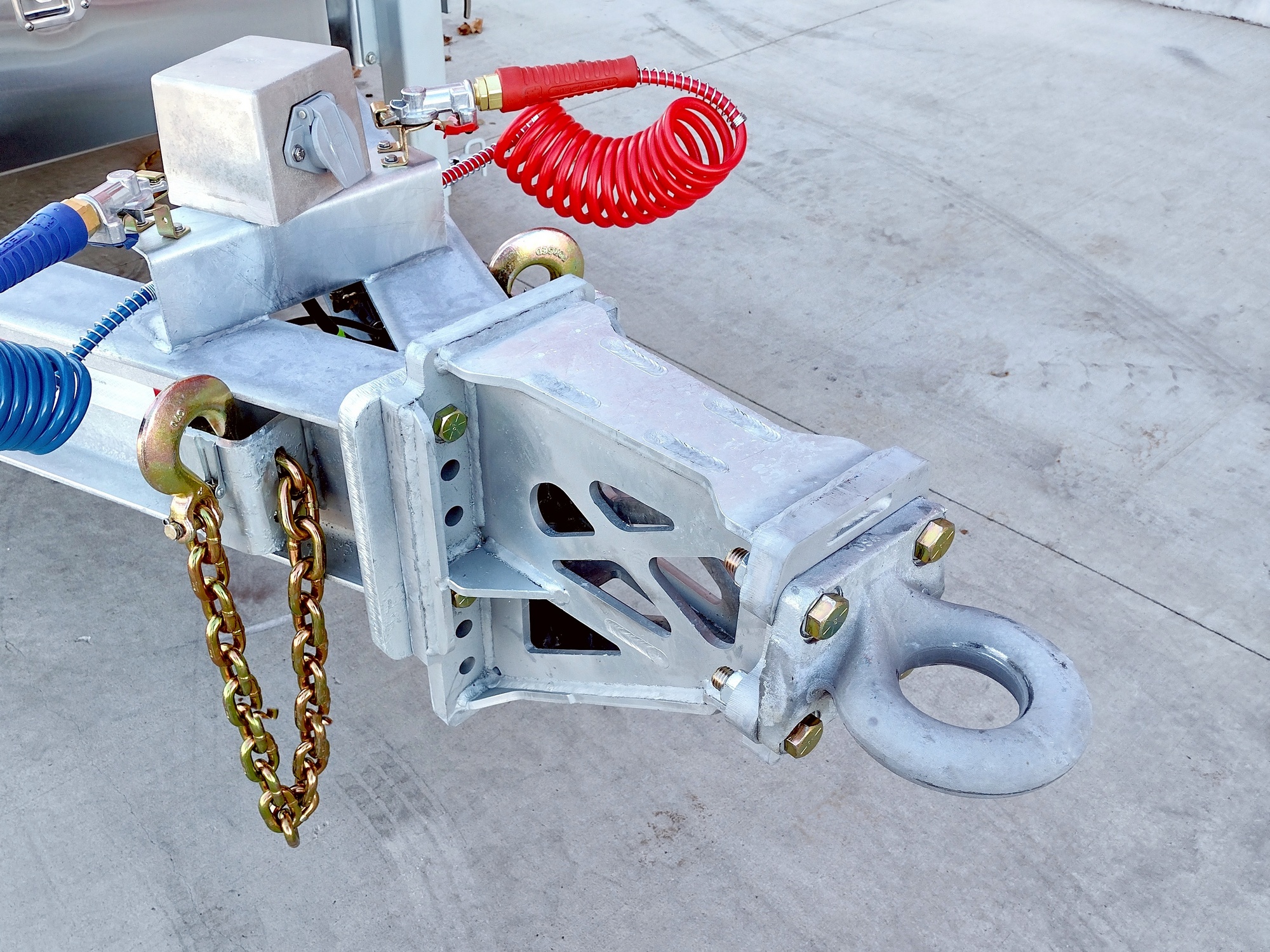

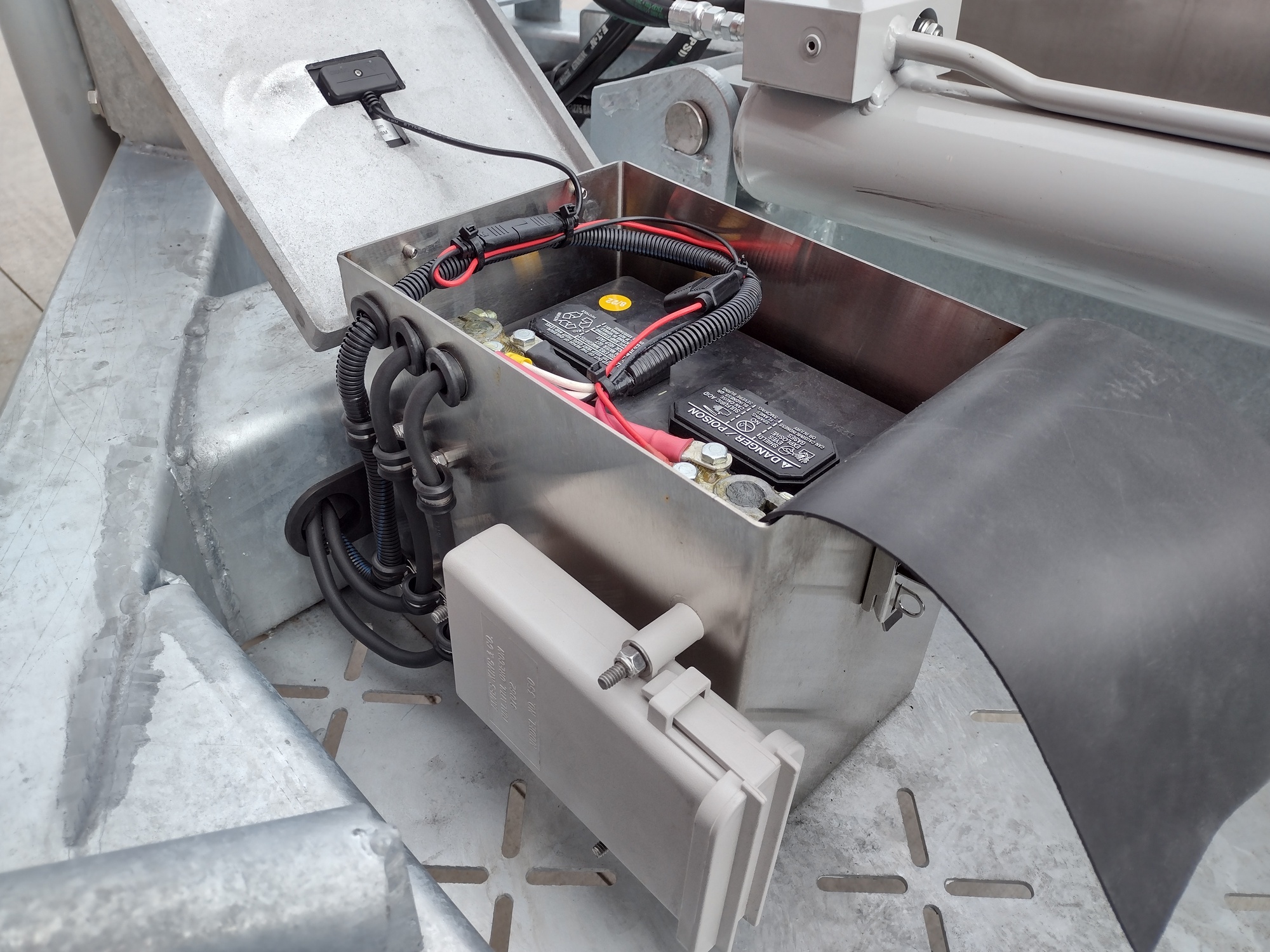

Offering versatility with compact size, the Model 1550 Reel & Cargo Trailer is a powerful tool for your crews. Enhance your crews' productivity with options like customized storage, reel carriers and more. Sauber Mfg. Co. has the experience, designs and high-quality components to build durability into your customized trailer. Sauber Mfg. Co.’s standard features like tube construction, galvanized finish and available custom stainless-steel toolboxes ensure your reel & cargo trailer will handle the harsh utility construction environment for years to come.

Click here to view similar Sauber Mfg. Co. Trailers.

Capacity: 2300#

GVWR: 4375#

Reel Size: 60"Dia x 40"W

Dimensions: 12'L x 79"W