Substation Recovery Trailer

Model 1561

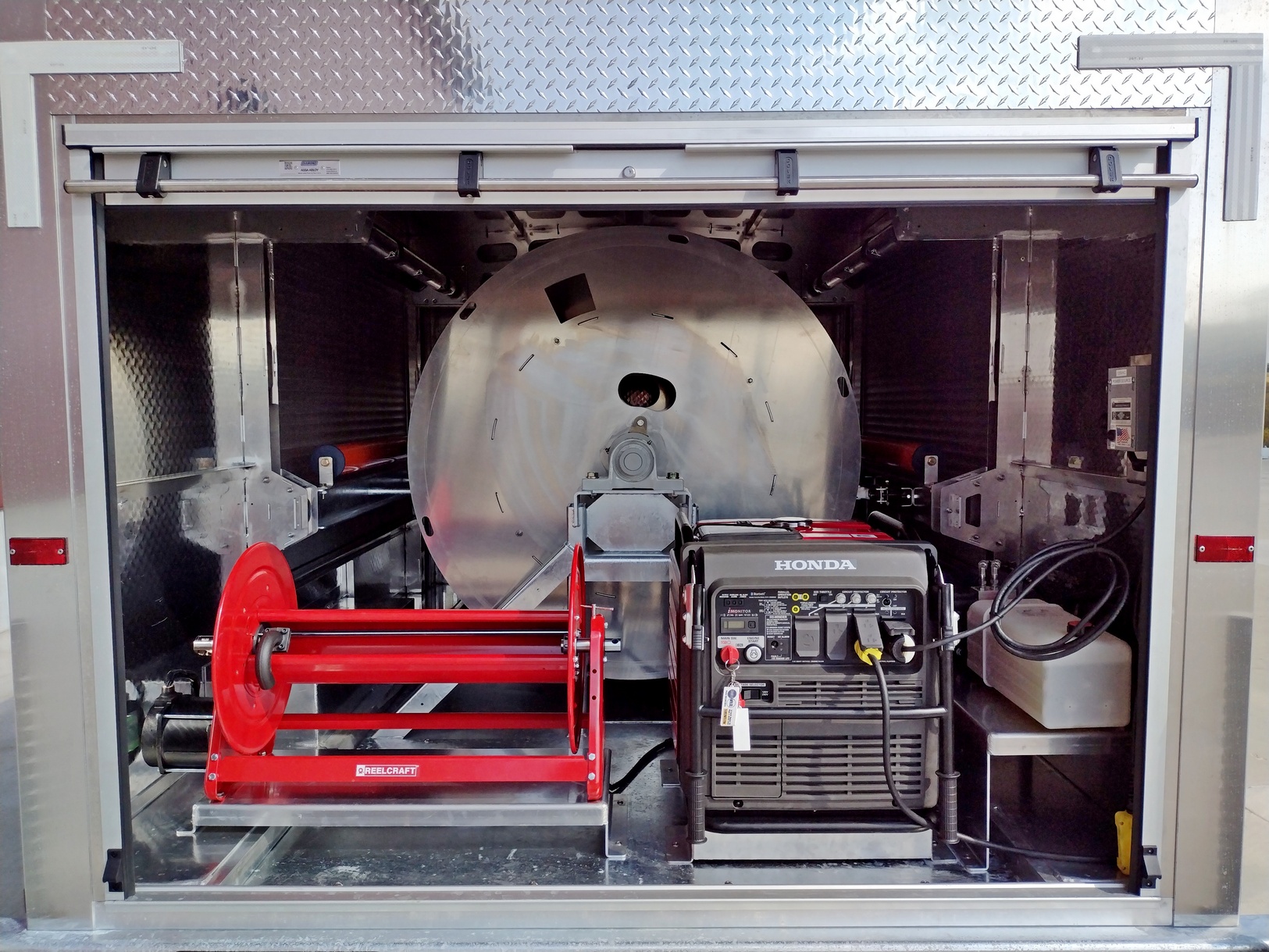

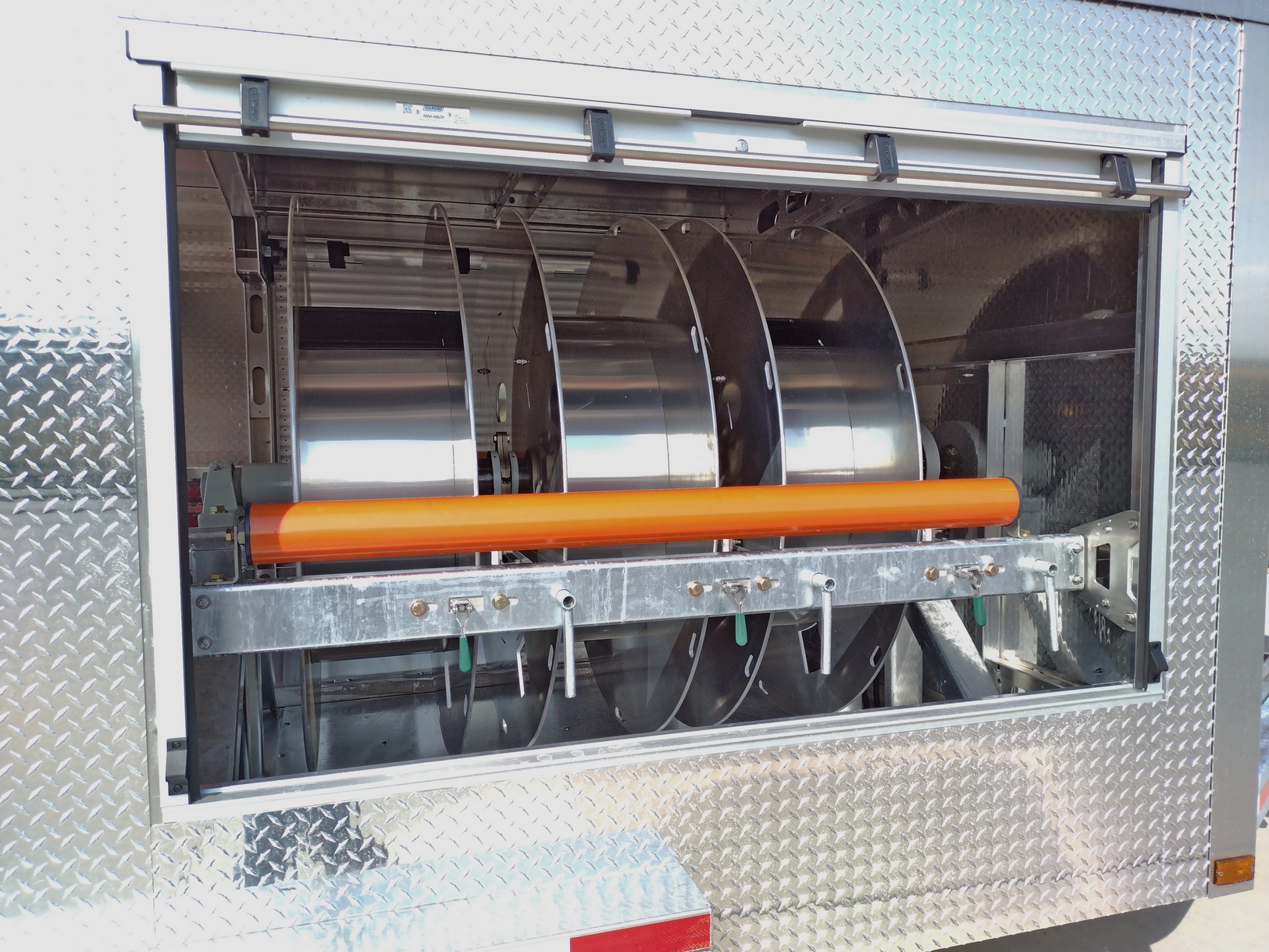

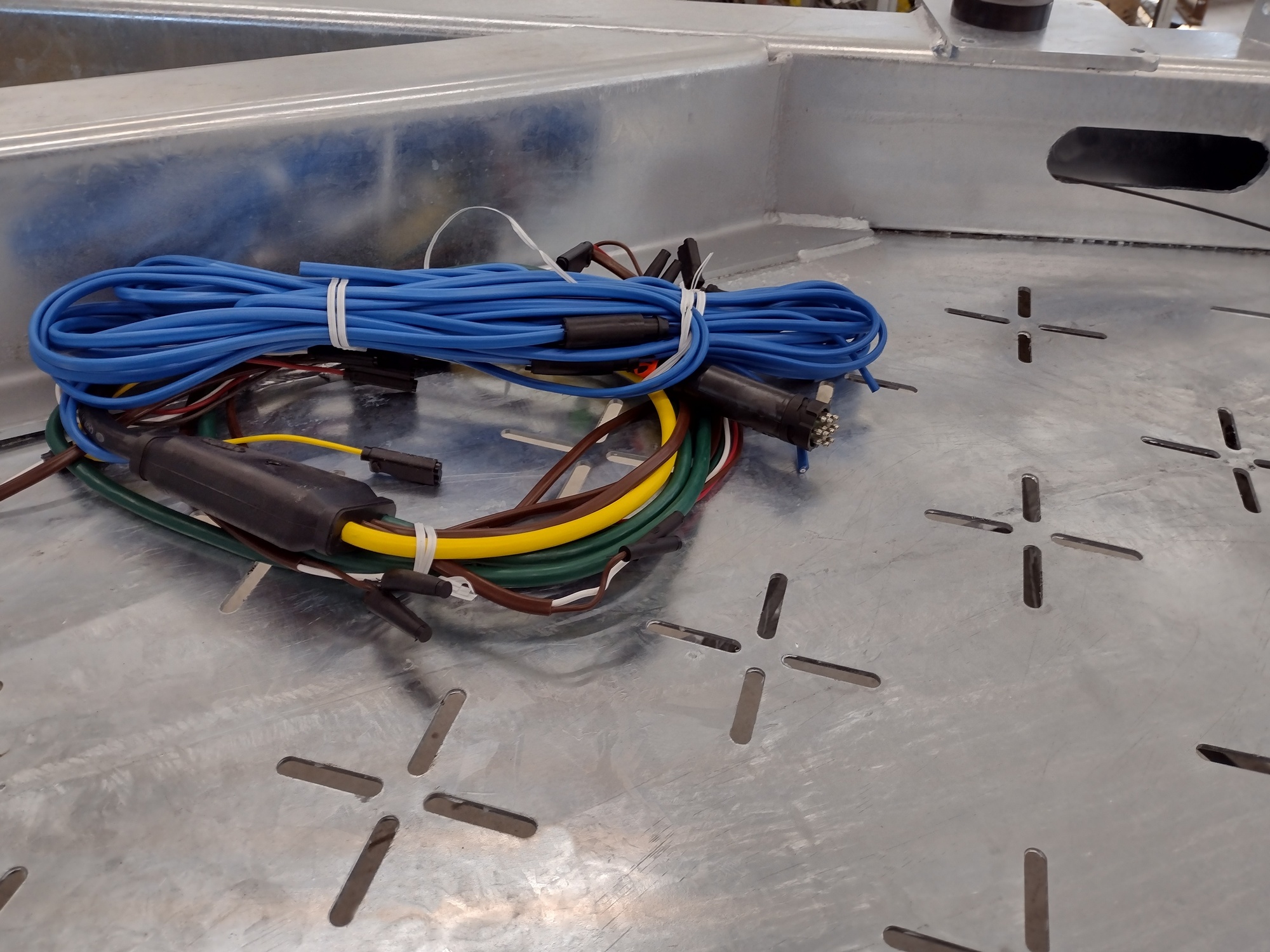

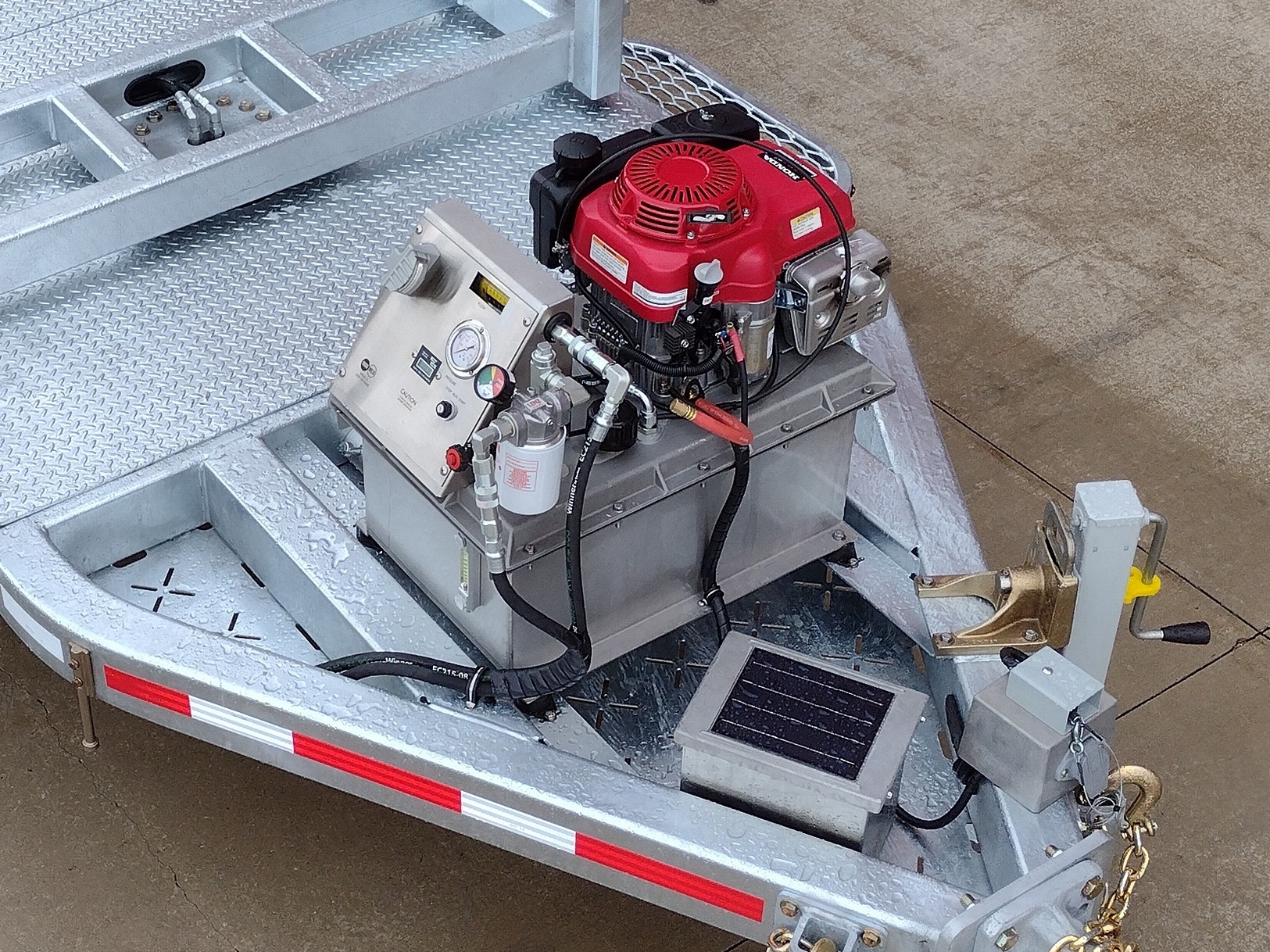

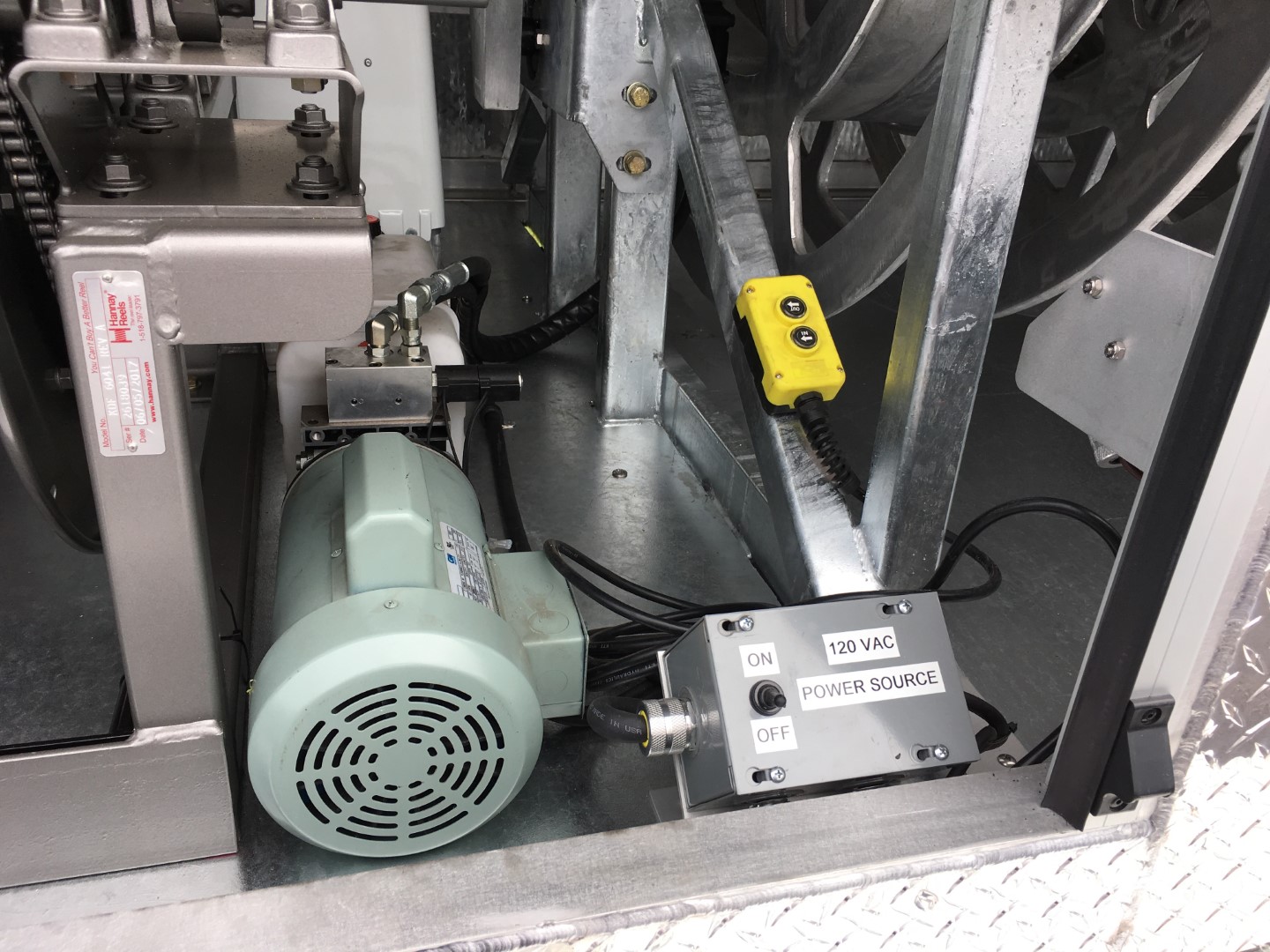

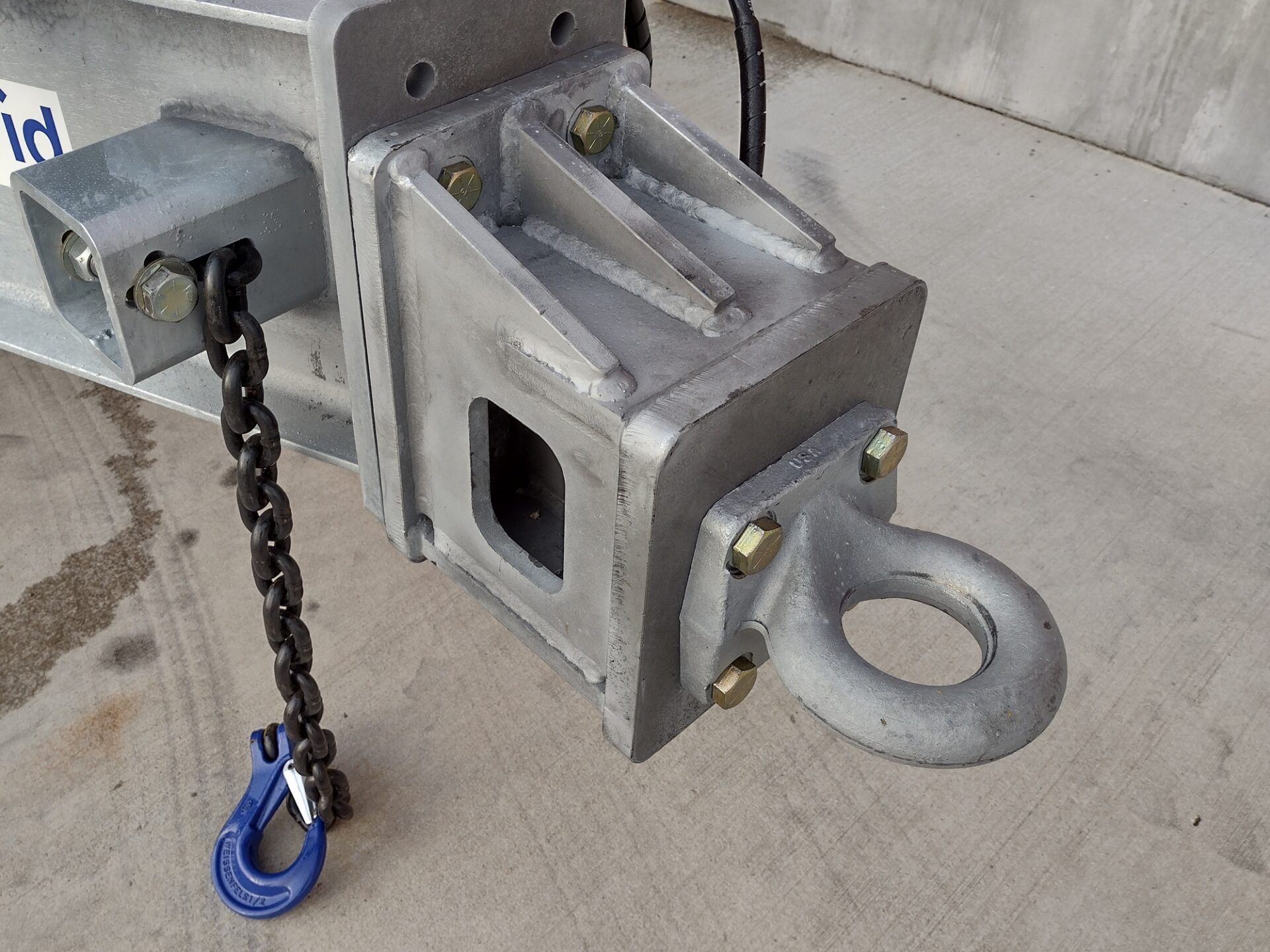

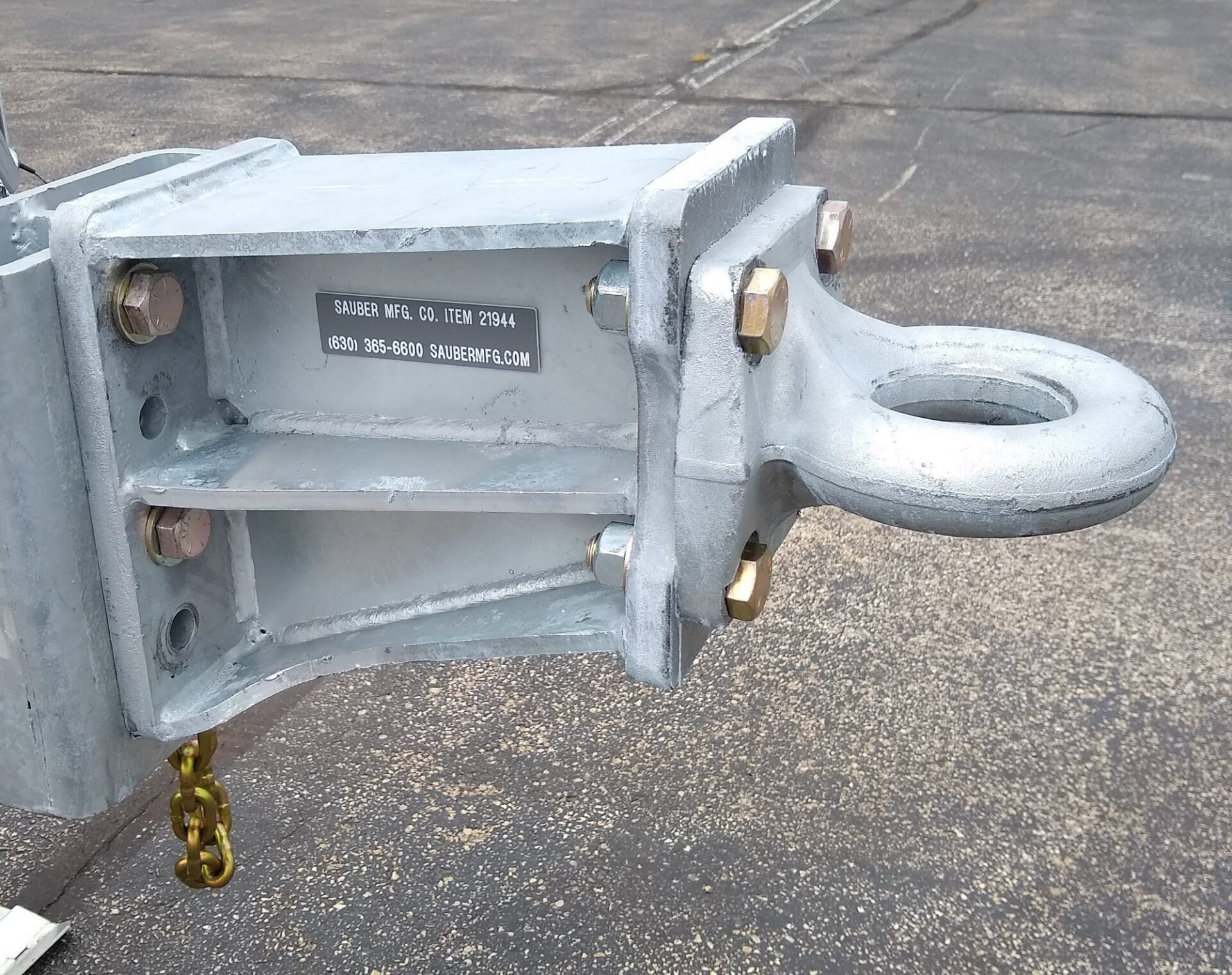

The Model 1561 Substation Recovery Trailer is dedicated connection cable trailer that speeds substation restoration efforts. The trailer includes selectable reel rotation, configurable storage and options for power, enclosures and additional support equipment for other operations. Solid model designs combine standardized components and specification features to match your work-set. The substation recovery trailer will meet your operation requirements with durable features like non-rusting components, galvanized finish and a durable power drive system.

Click here to view similar Sauber Mfg. Co. trailers.

Capacity: 9250#

GVWR: 16450#

Cable Capacity: 9

Reel Size: (3) 54"OD x 34"ID x 27"W Aluminum 3-Section Reels

Dimensions: 20'L x 96"W