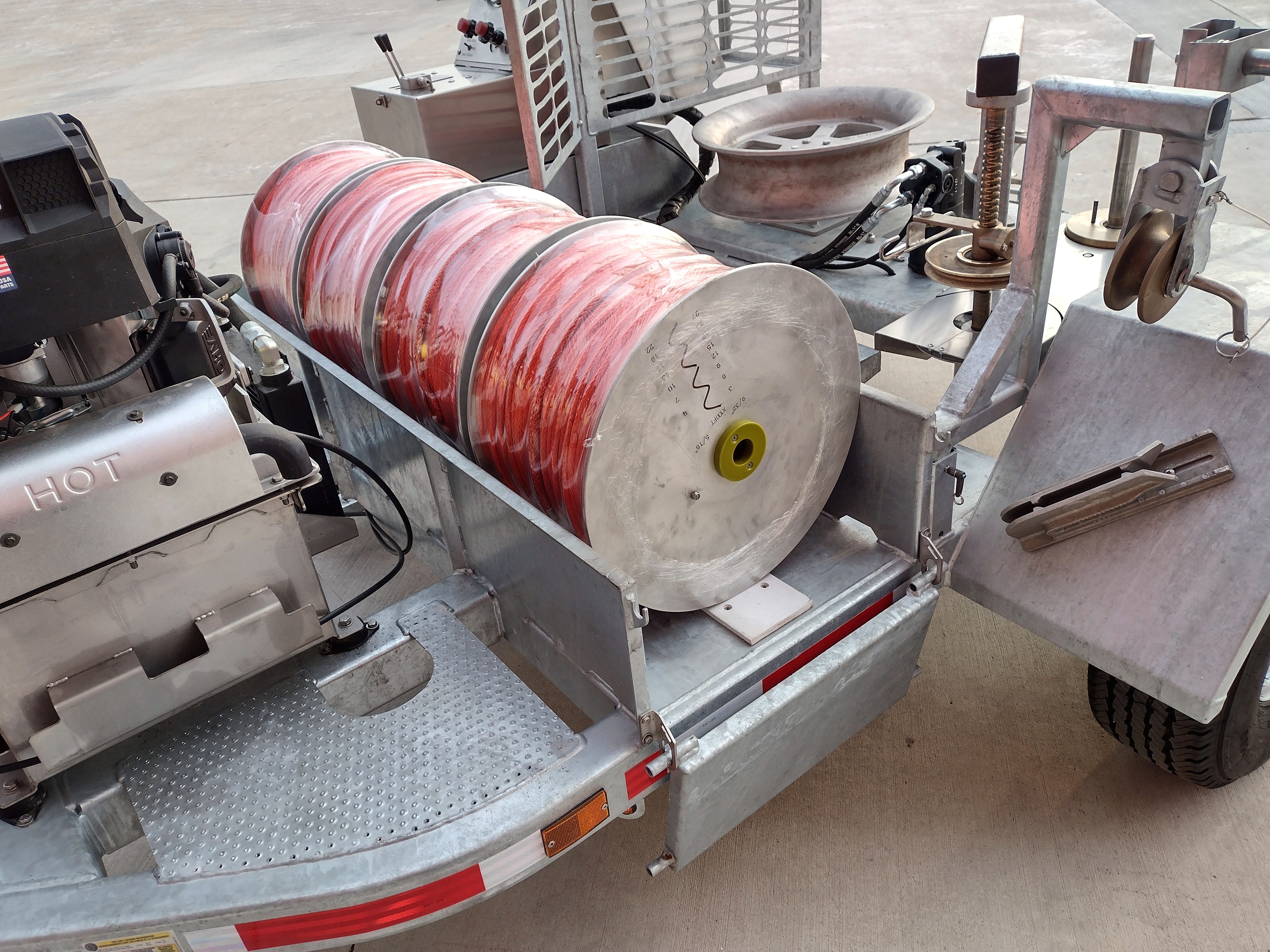

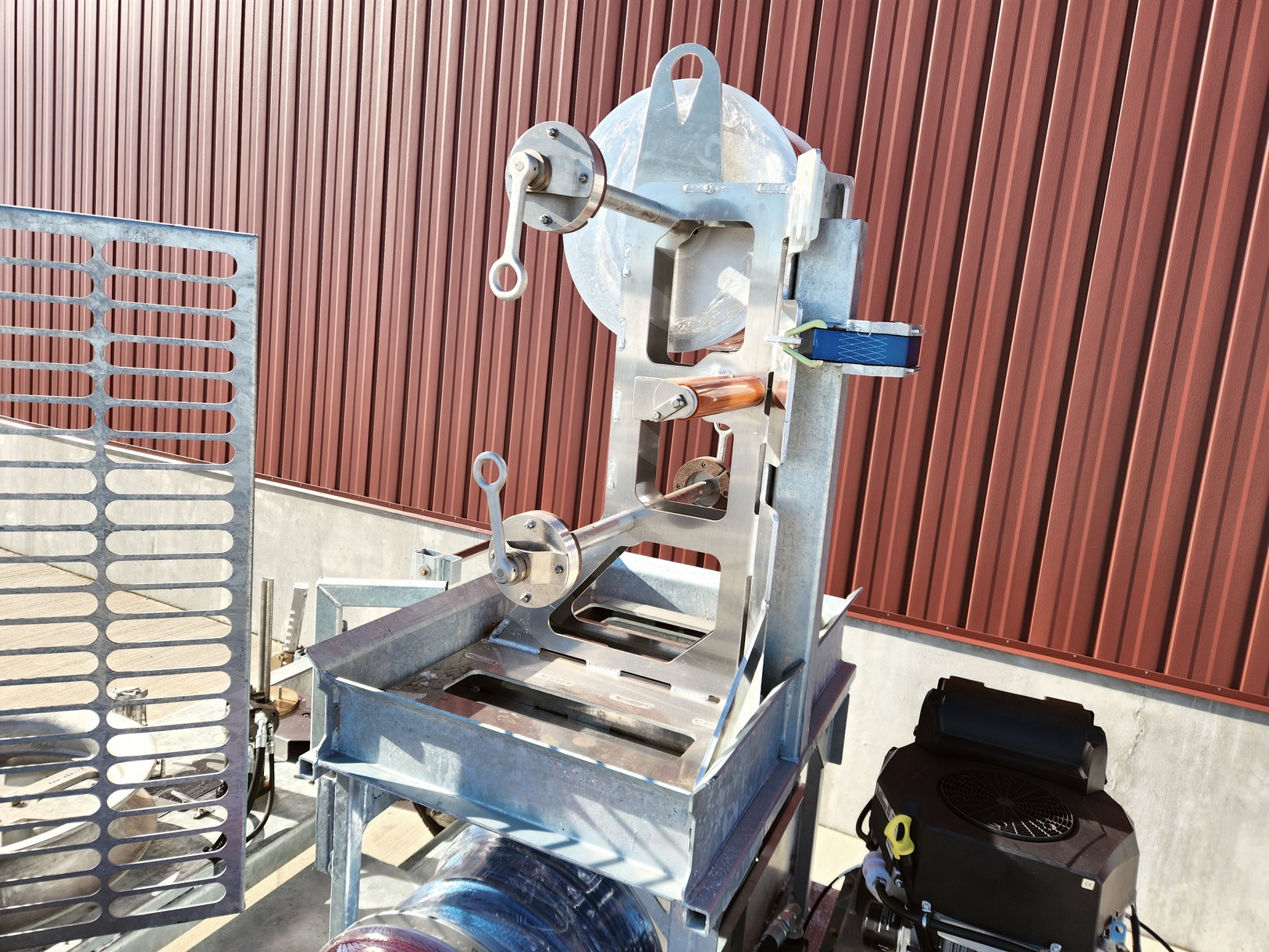

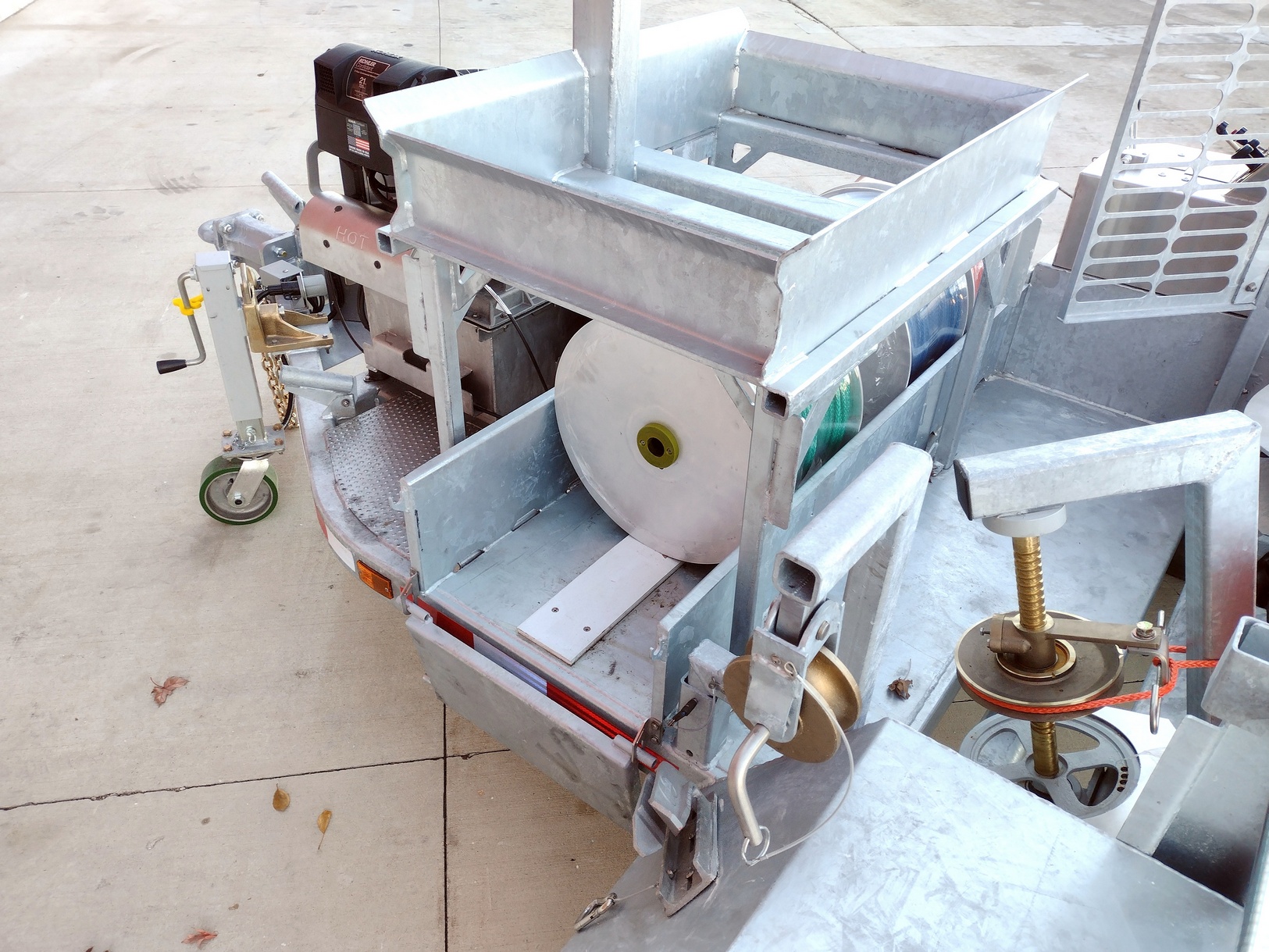

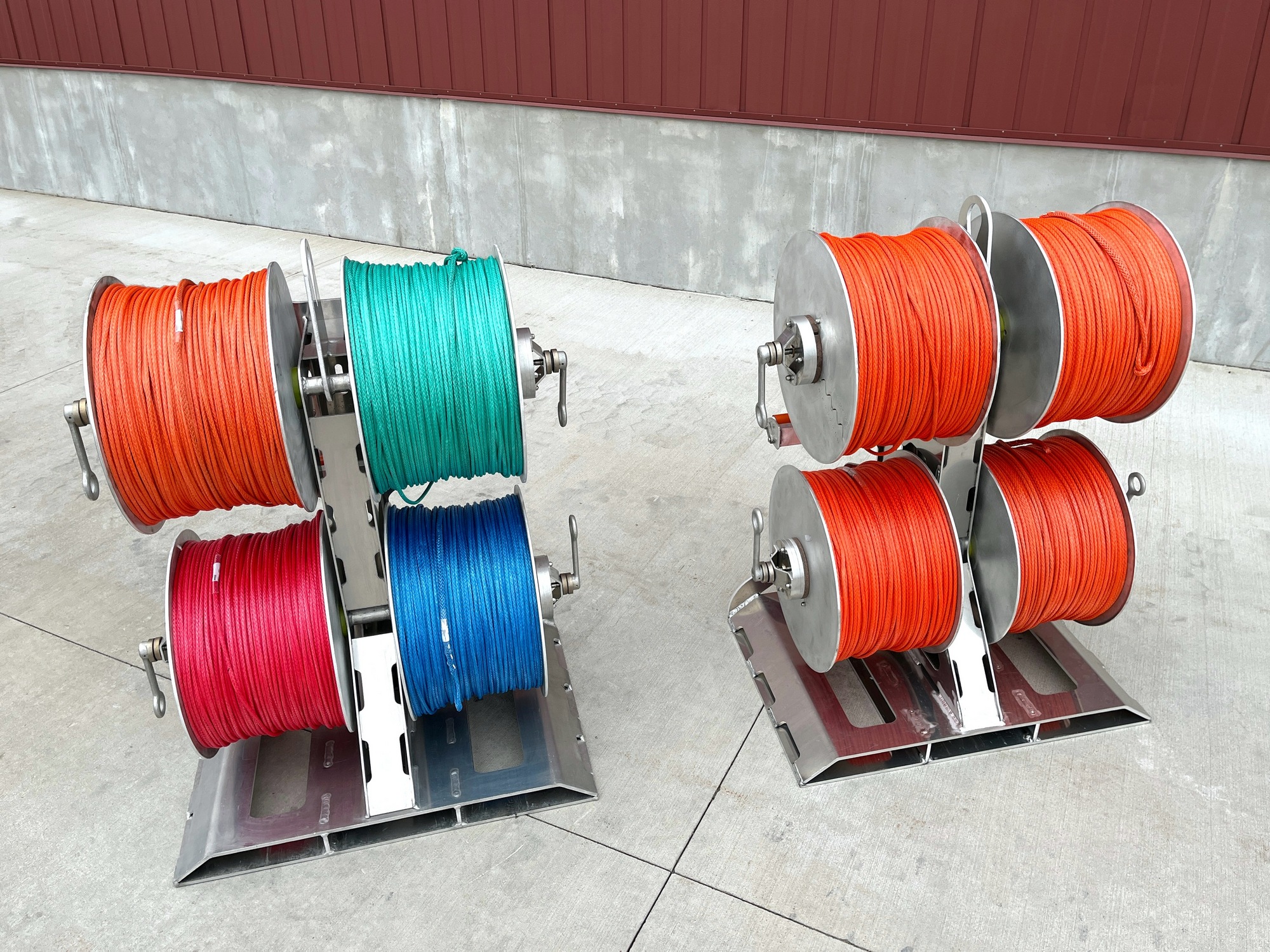

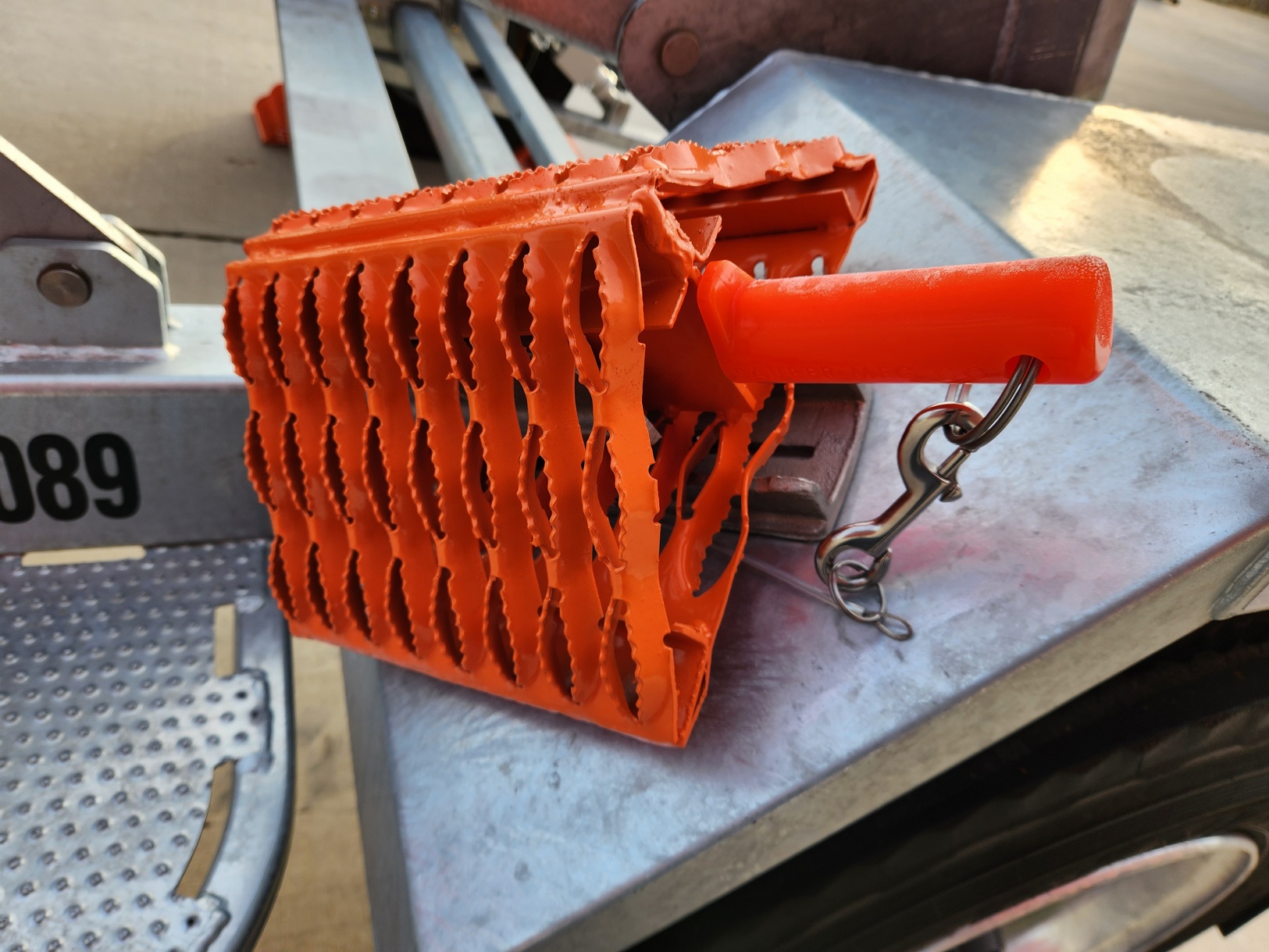

Puller w/ (4) Rope Filled Cassettes

Model 1570-B

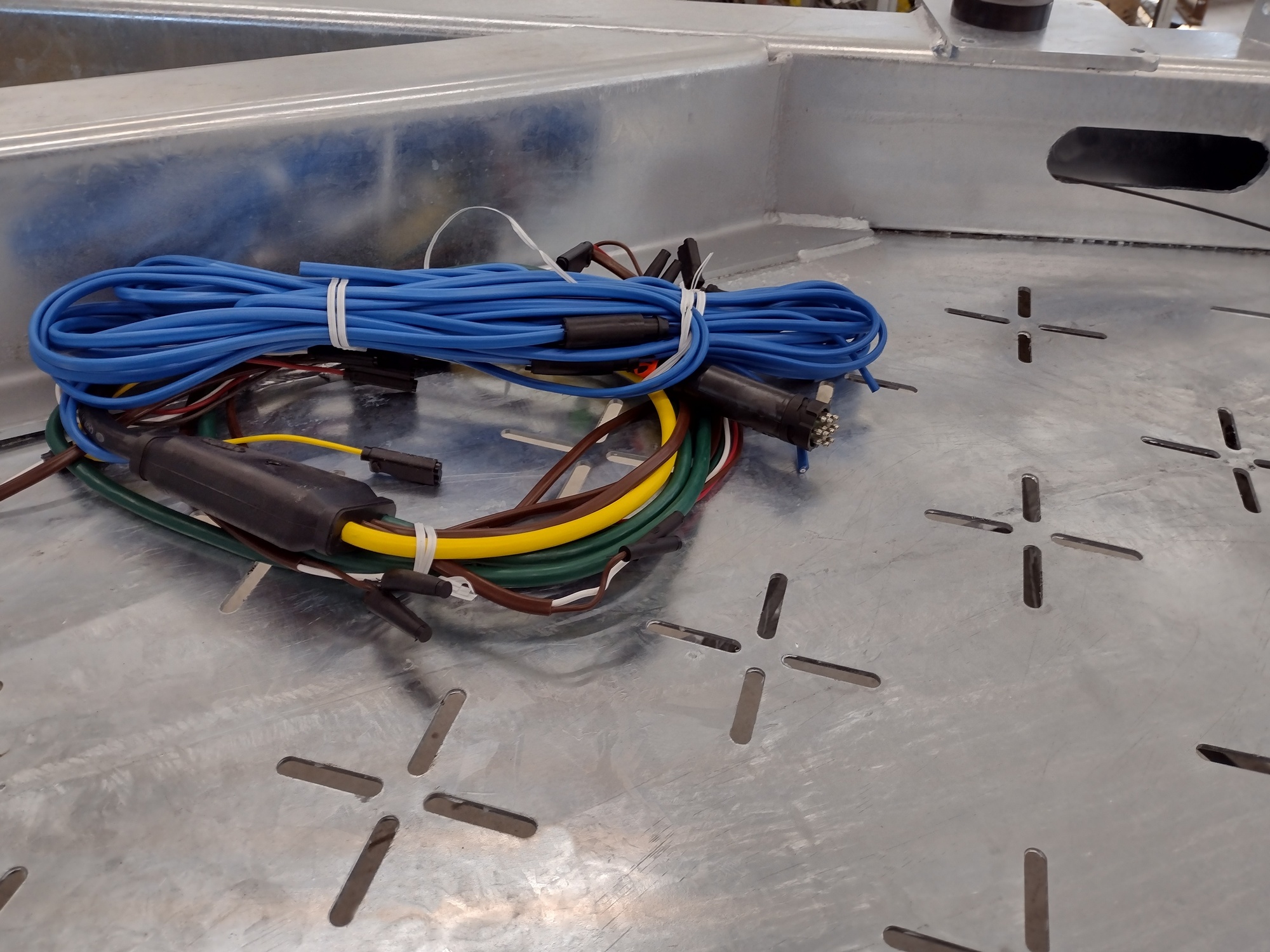

Our Puller is a revolutionary, innovative tool for distribution line construction. Not only does it offer distribution-capable pulling power in a small, easy-to-position design, it re-invents the way stringing can be done. In short, you’ll get more conductor up in a shorter amount of time. And the same puller for overhead is used for underground construction. Both applications benefit from simple operator control and the constant speed, constant tension design for smooth, even pulls that are unrestricted in length. More information is available at our Technical Resources Page. Contact us for an in-depth review.

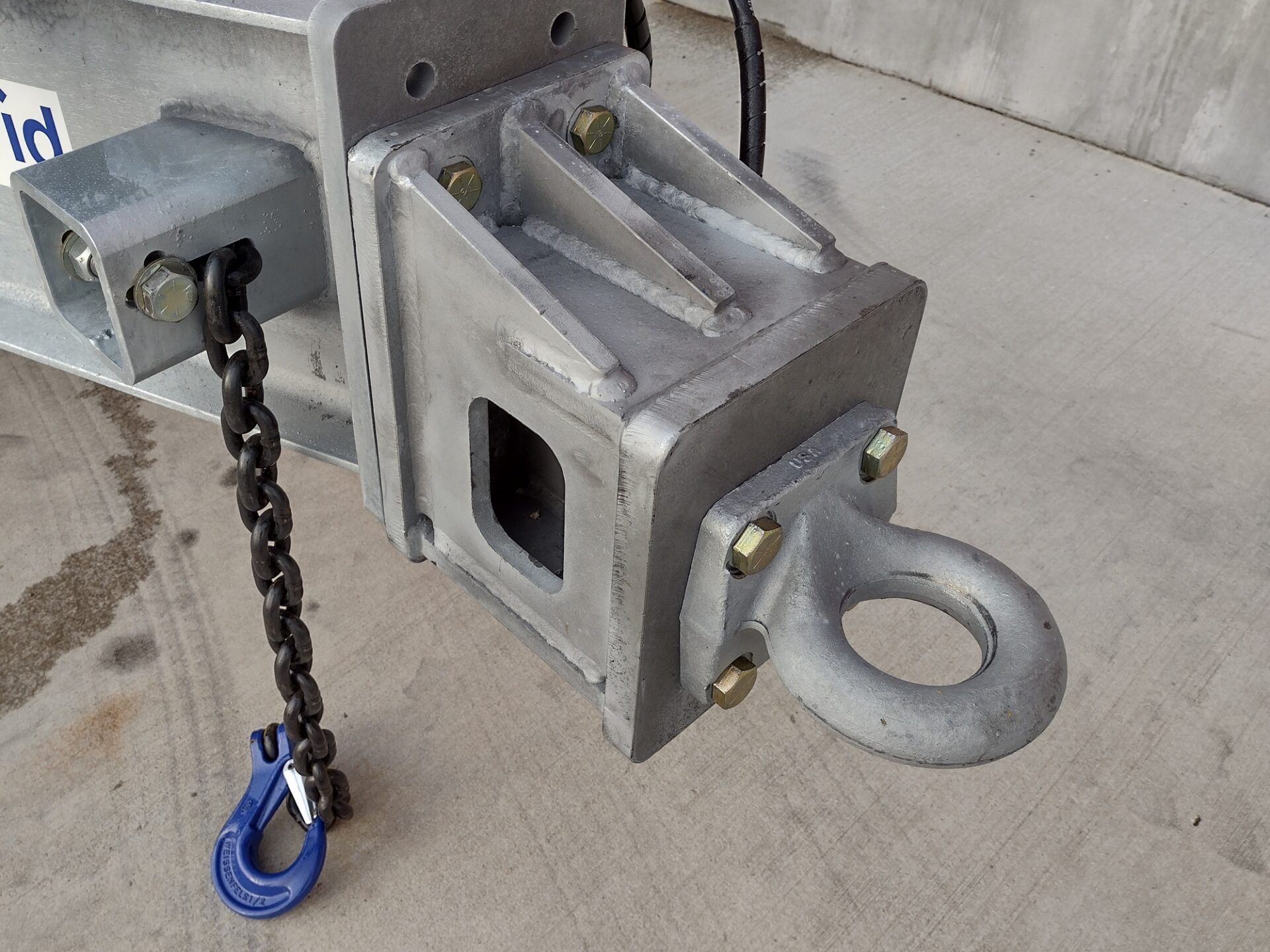

Capacity: 2100 lbs

Dimensions: 13'L x 94"W

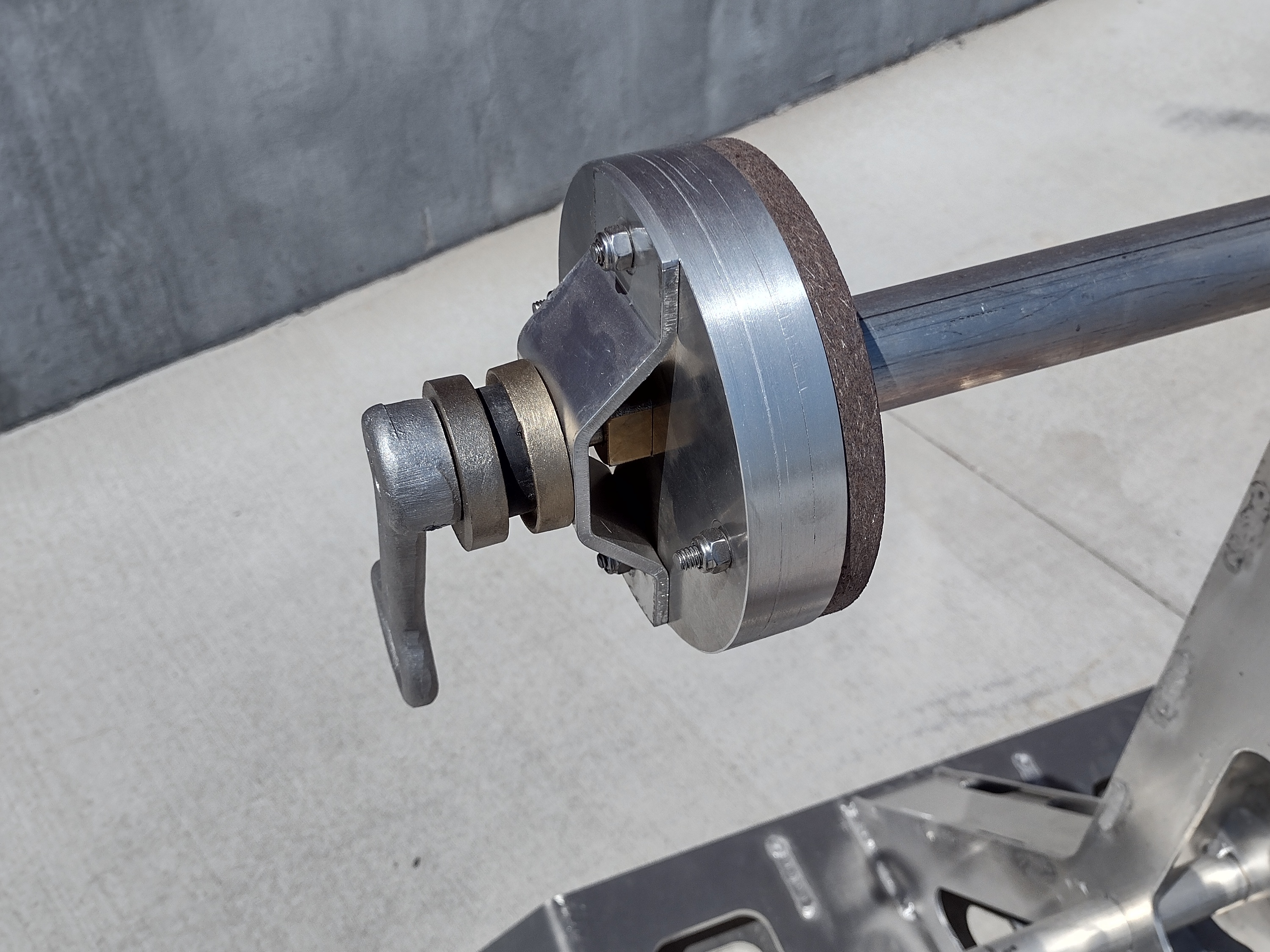

Axle: 6000 lbs

Brakes: 12" x 2", high performance

Suspension: Torflex

GVWR: 5200 lbs

Tires: 235/80R16, LR E

Rims: 6.00 x 16.0 Disc