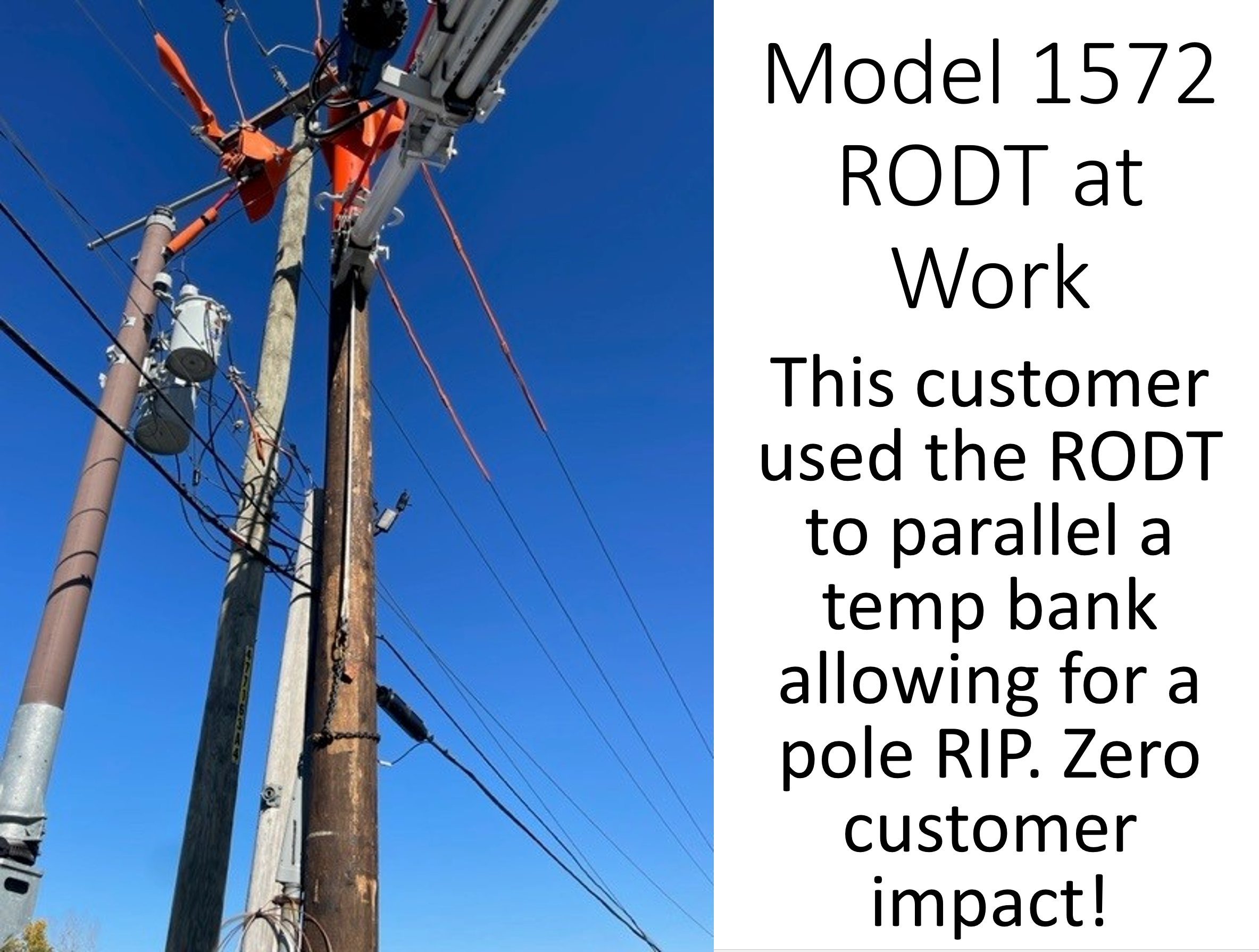

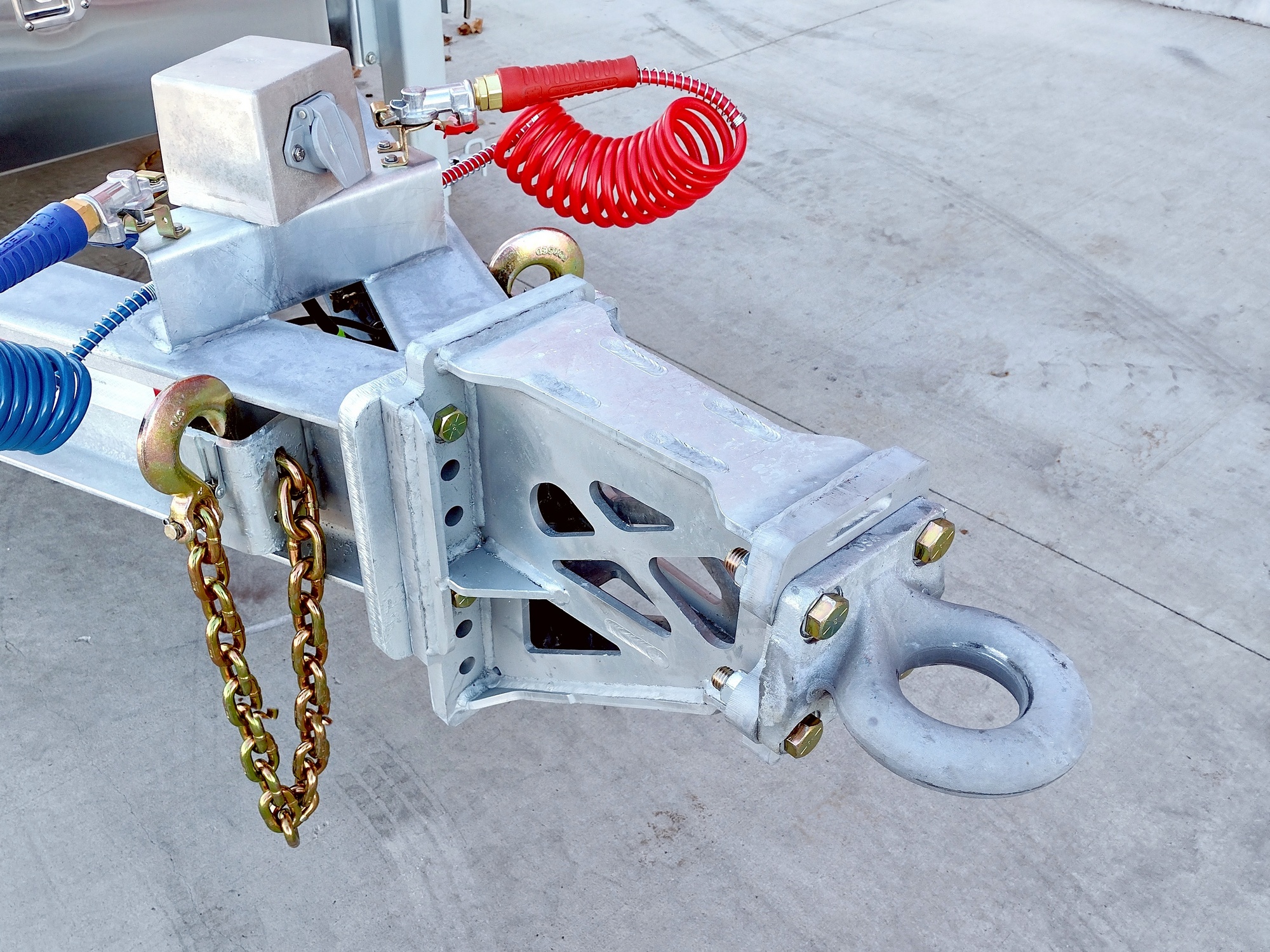

Rapid Overhead Deployment Trailer

Model 1572

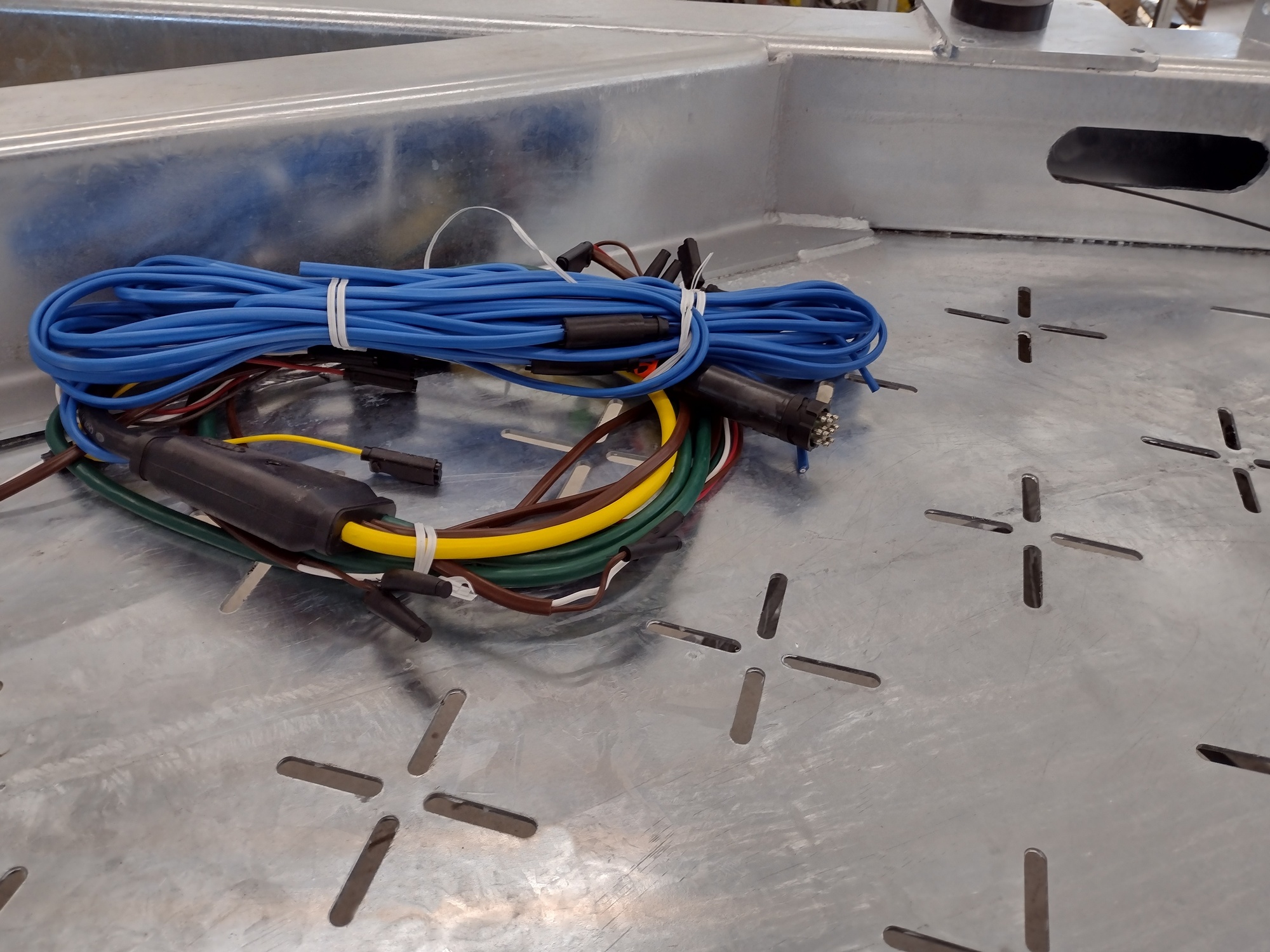

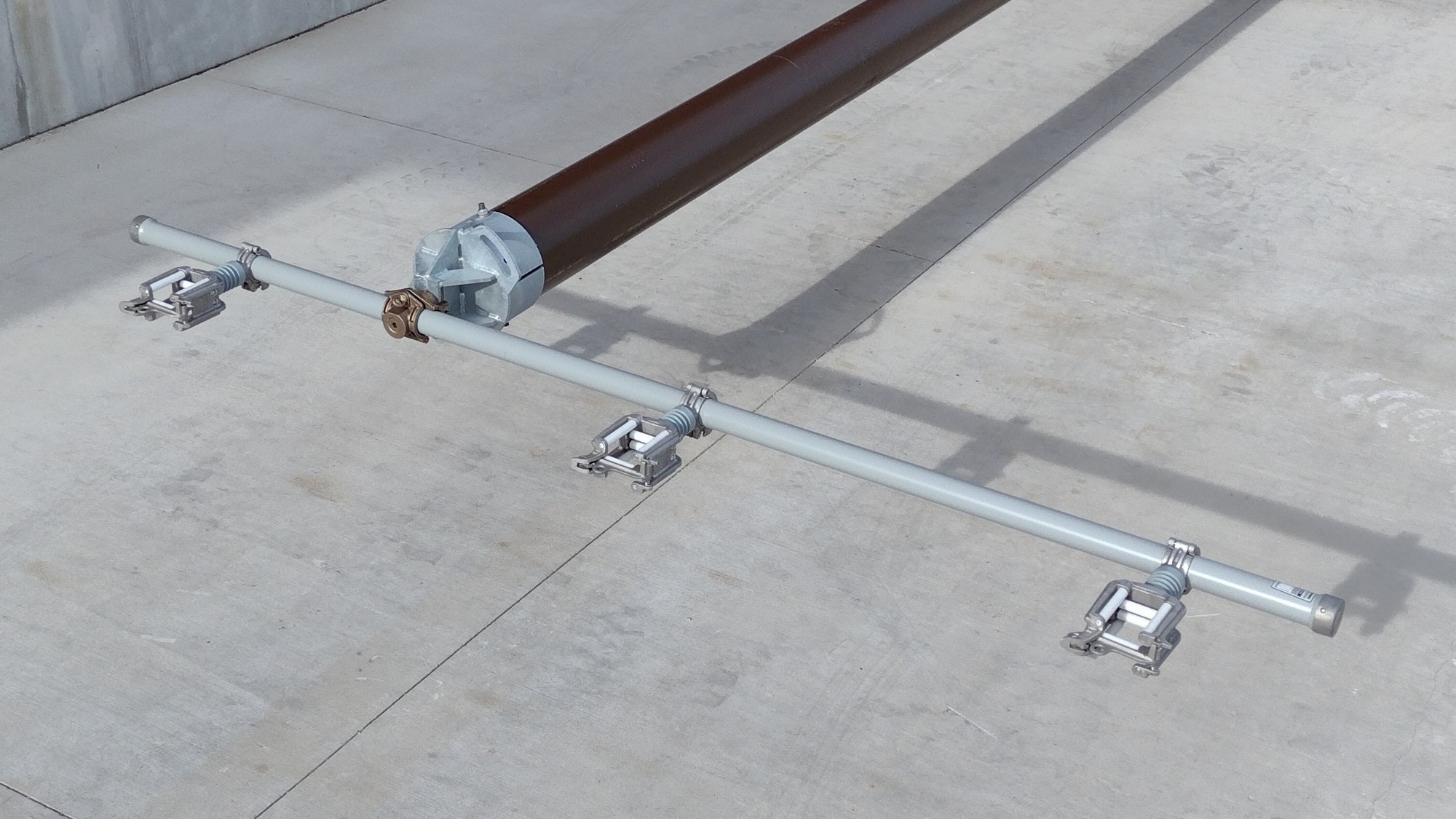

This is a tool for today’s environment. The Rapid Overhead Deployment Trailer was developed and tested in conjunction with a major utility to improve your CIADI numbers. Staged and ready to go, this tool supports energized conductors during repairs for shorter outage times. Designed to stay on the job site, it keeps your line trucks available for other work. The Rapid Overhead Deployment Trailer also improves performance with transformer replacements, planned pole replacement, temporary substation work, road crossing support, etc. Contact us to explore this method changing product.

Click here to see related equipment.

Capacity: 1000# Vertical Lift, 3000# Vertical Total Load; Tested 21,778 ft-lb Moment Load

GVWR: 9950#

Dimensions: 24’L x 96″W x 11’2″H

Patent 10,626,632