Beavertail Equipment Trailer

Model 1580-BT

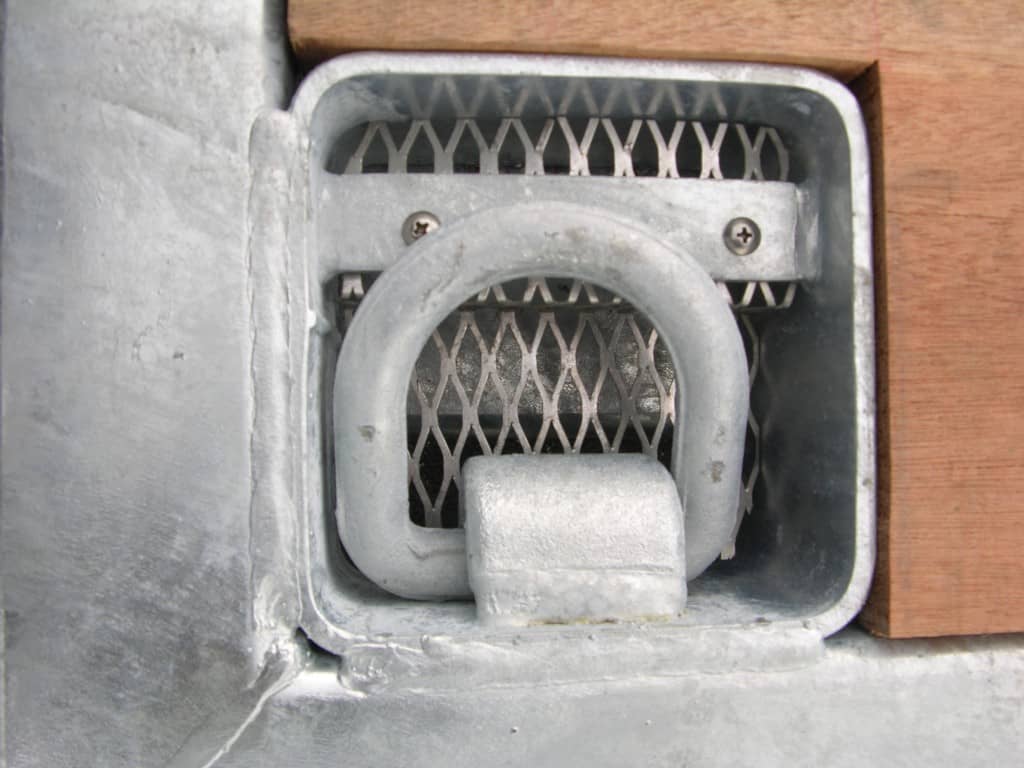

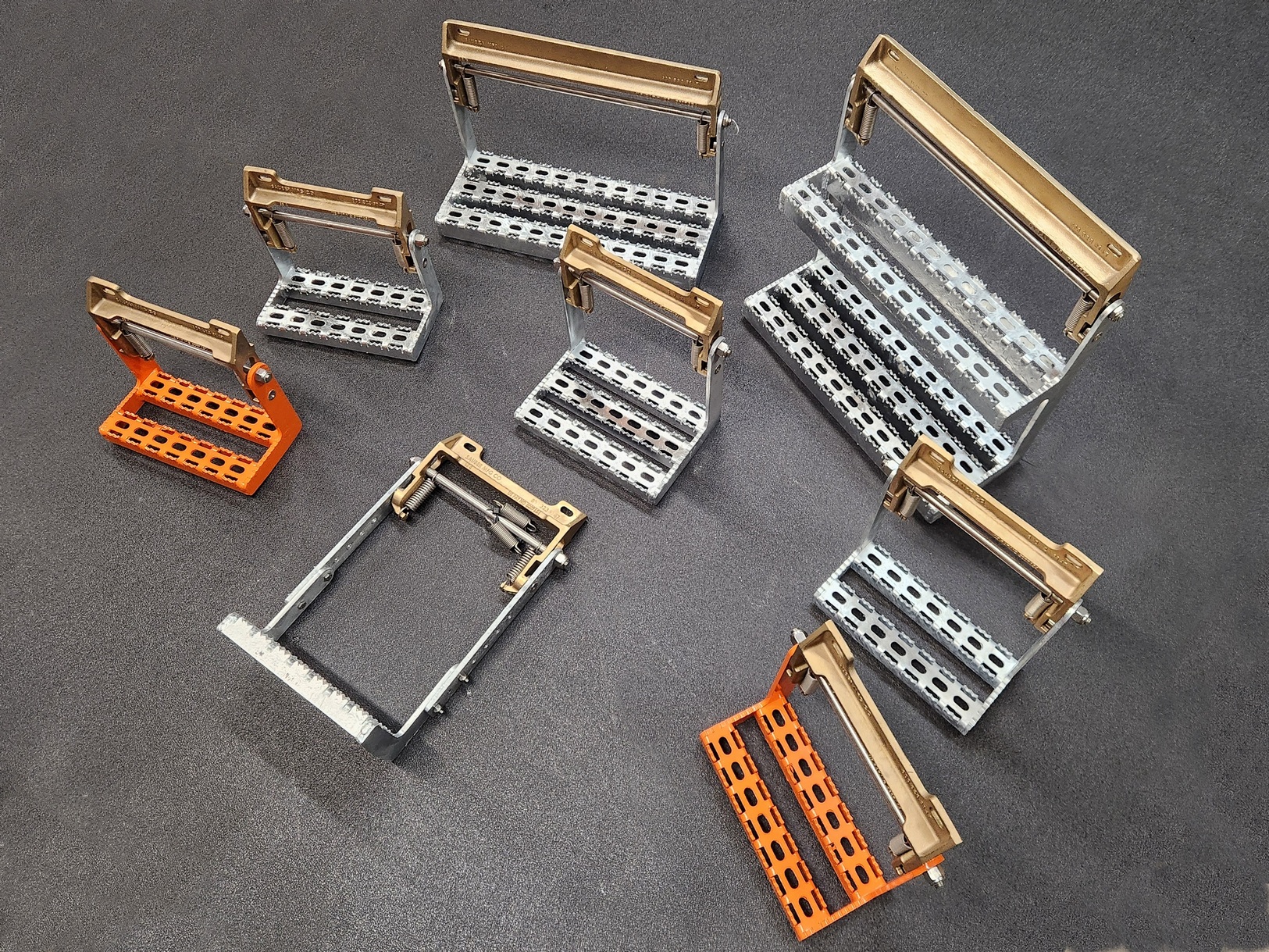

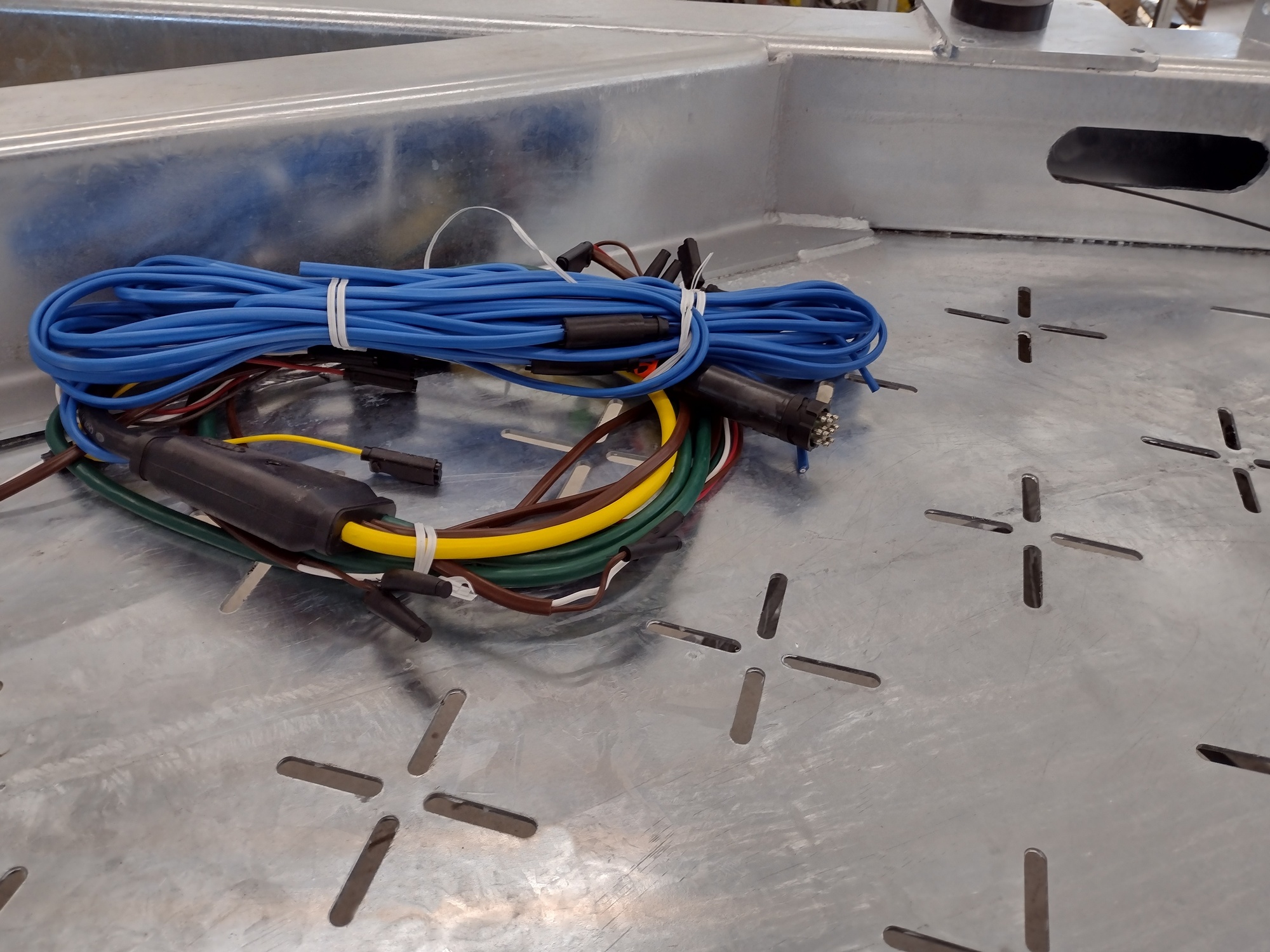

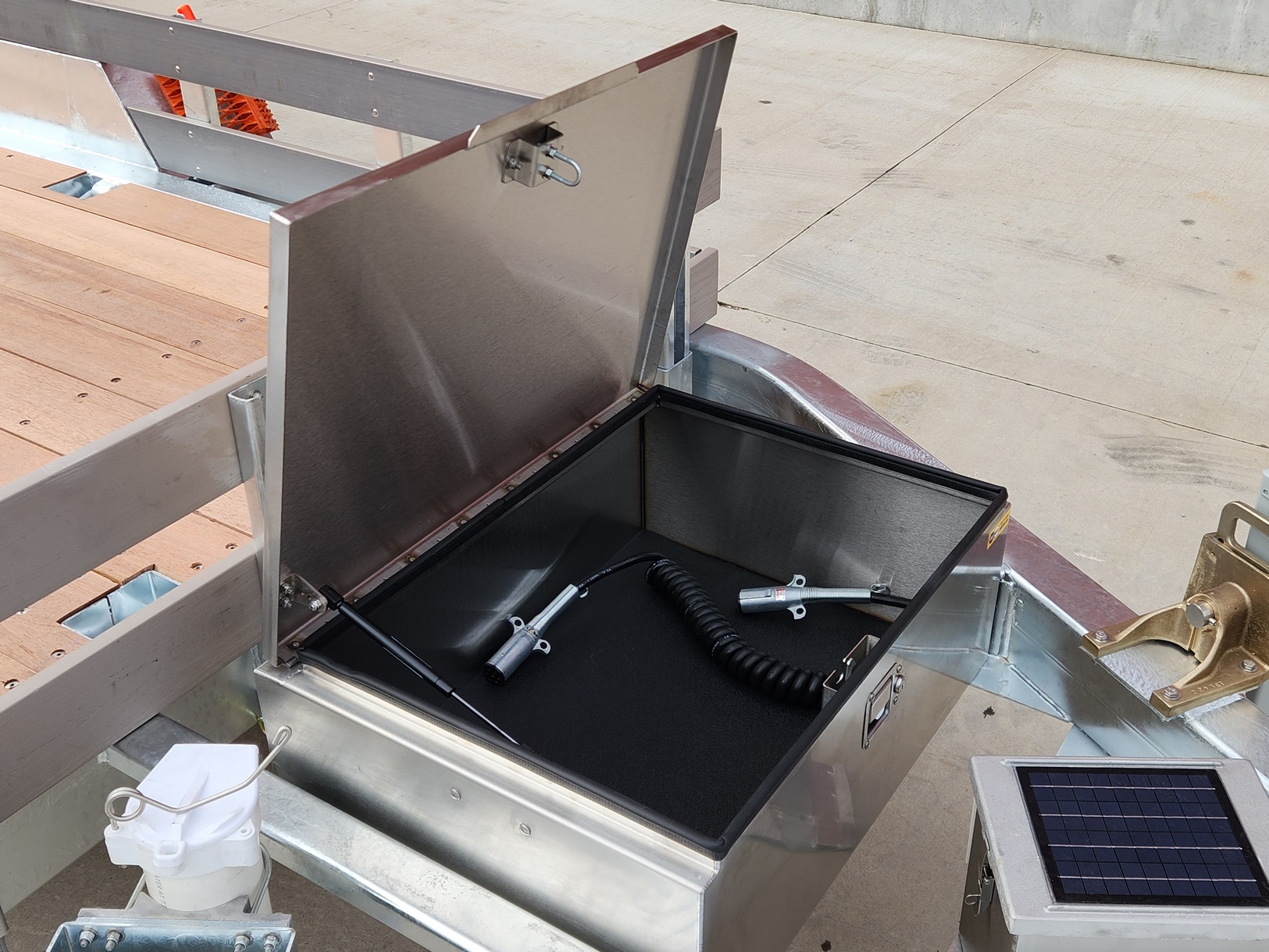

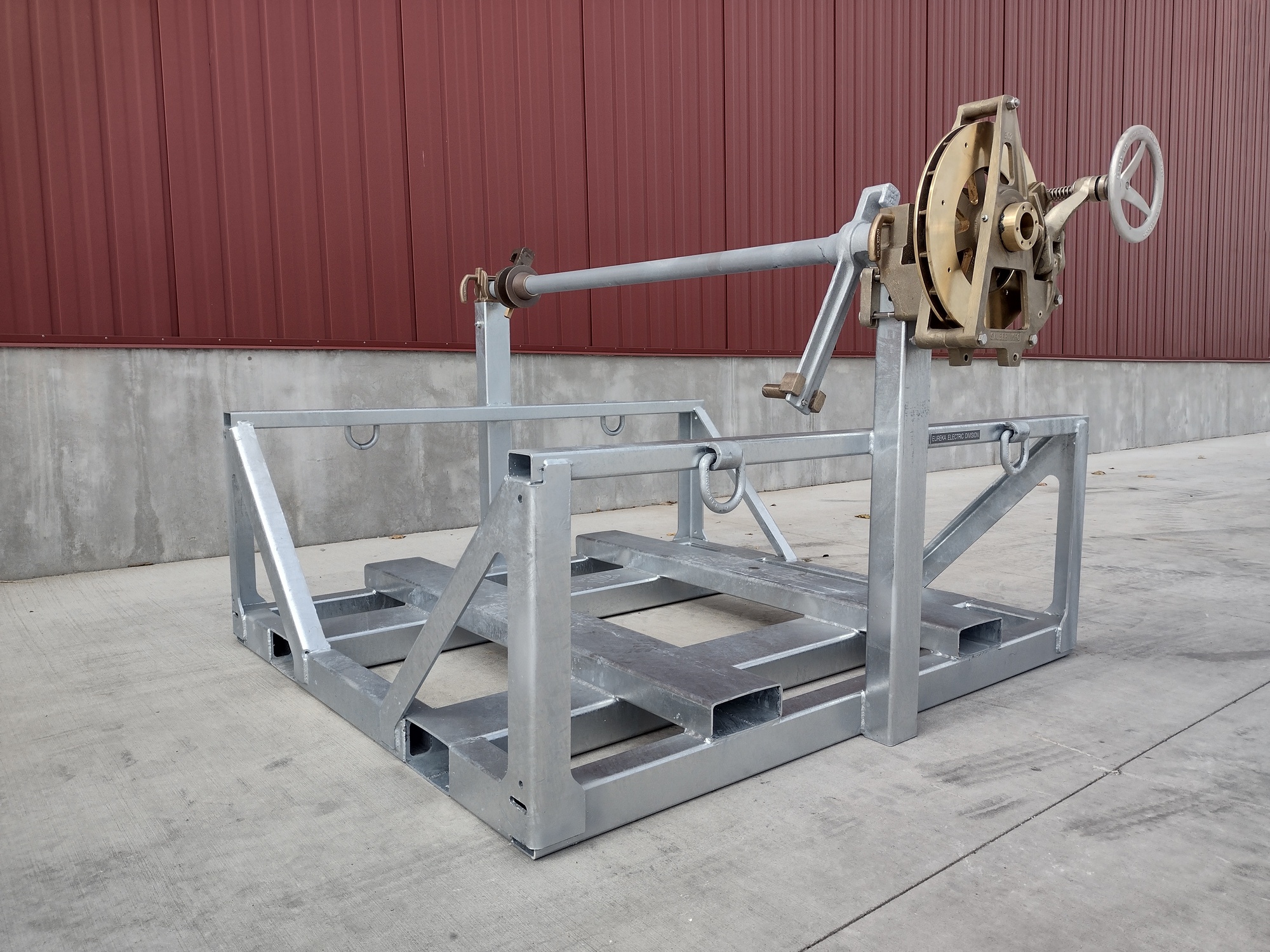

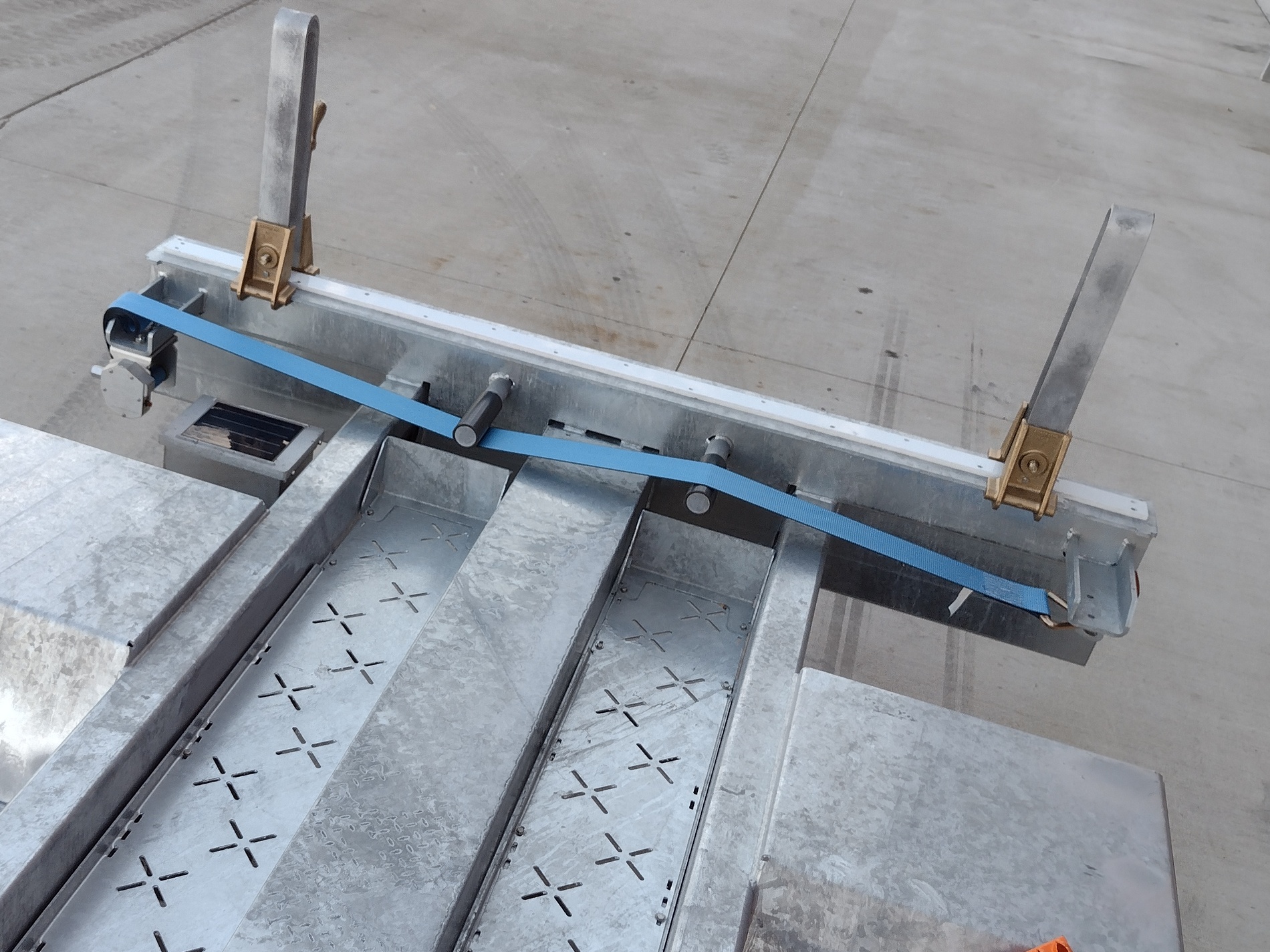

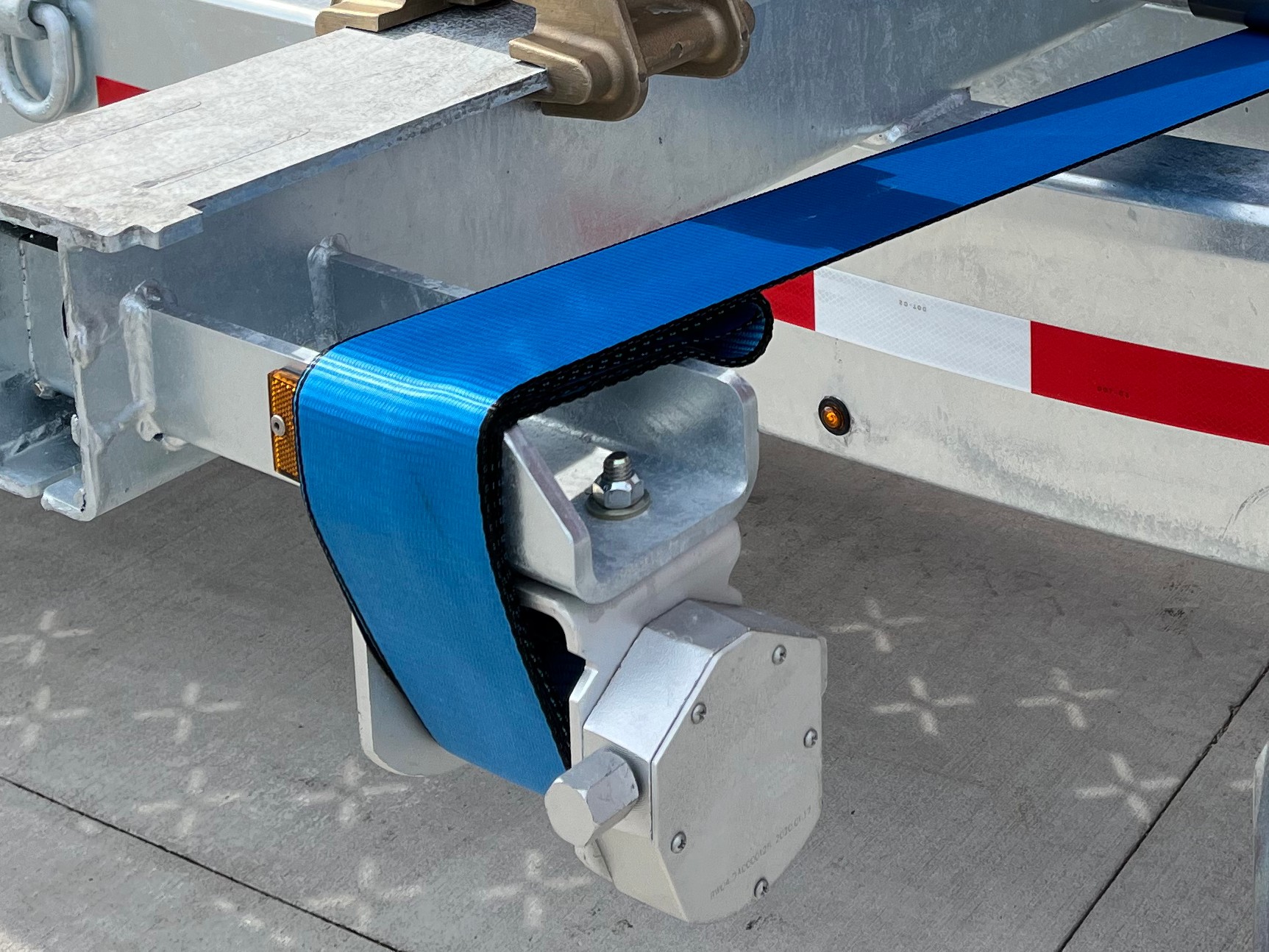

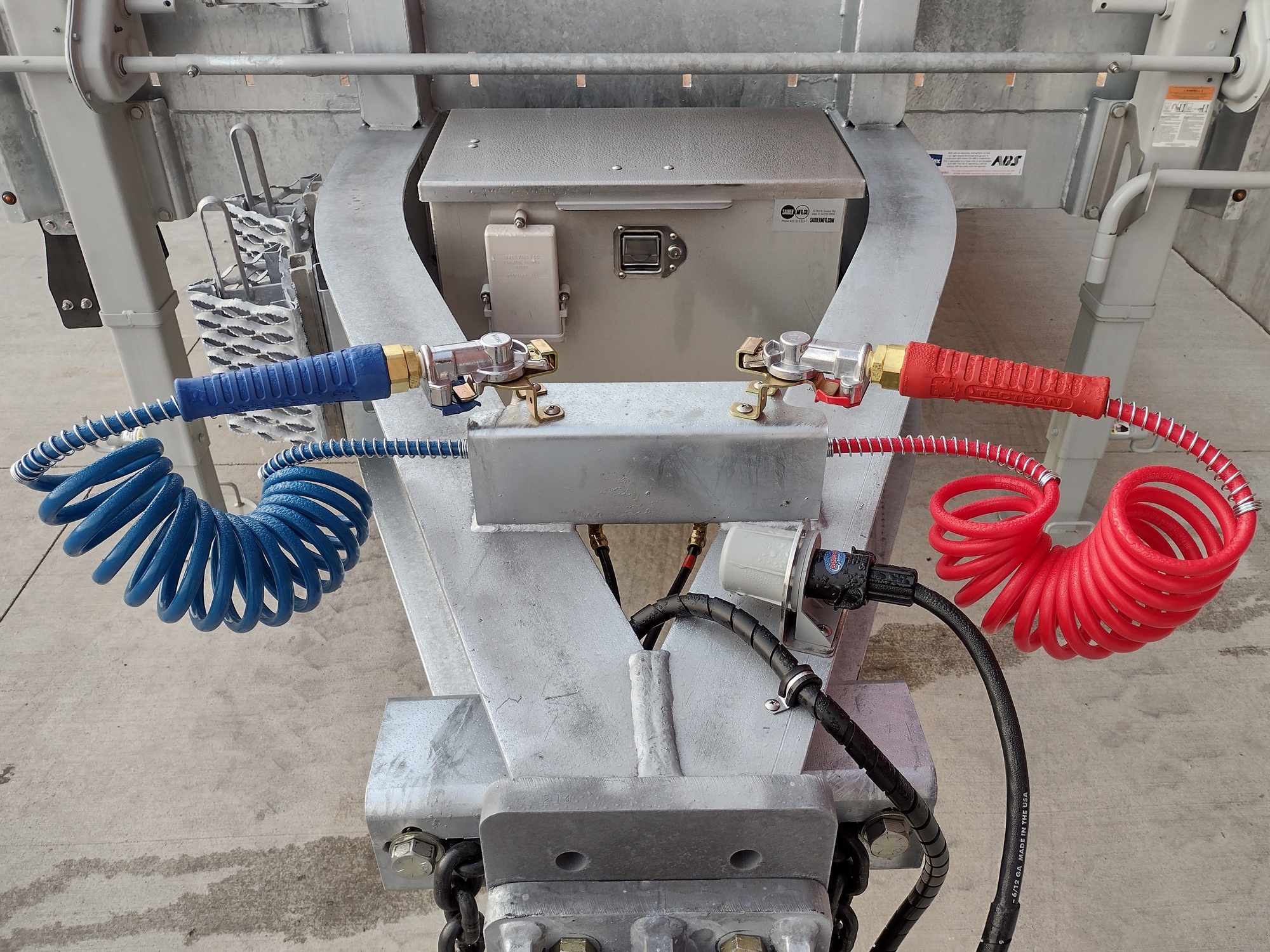

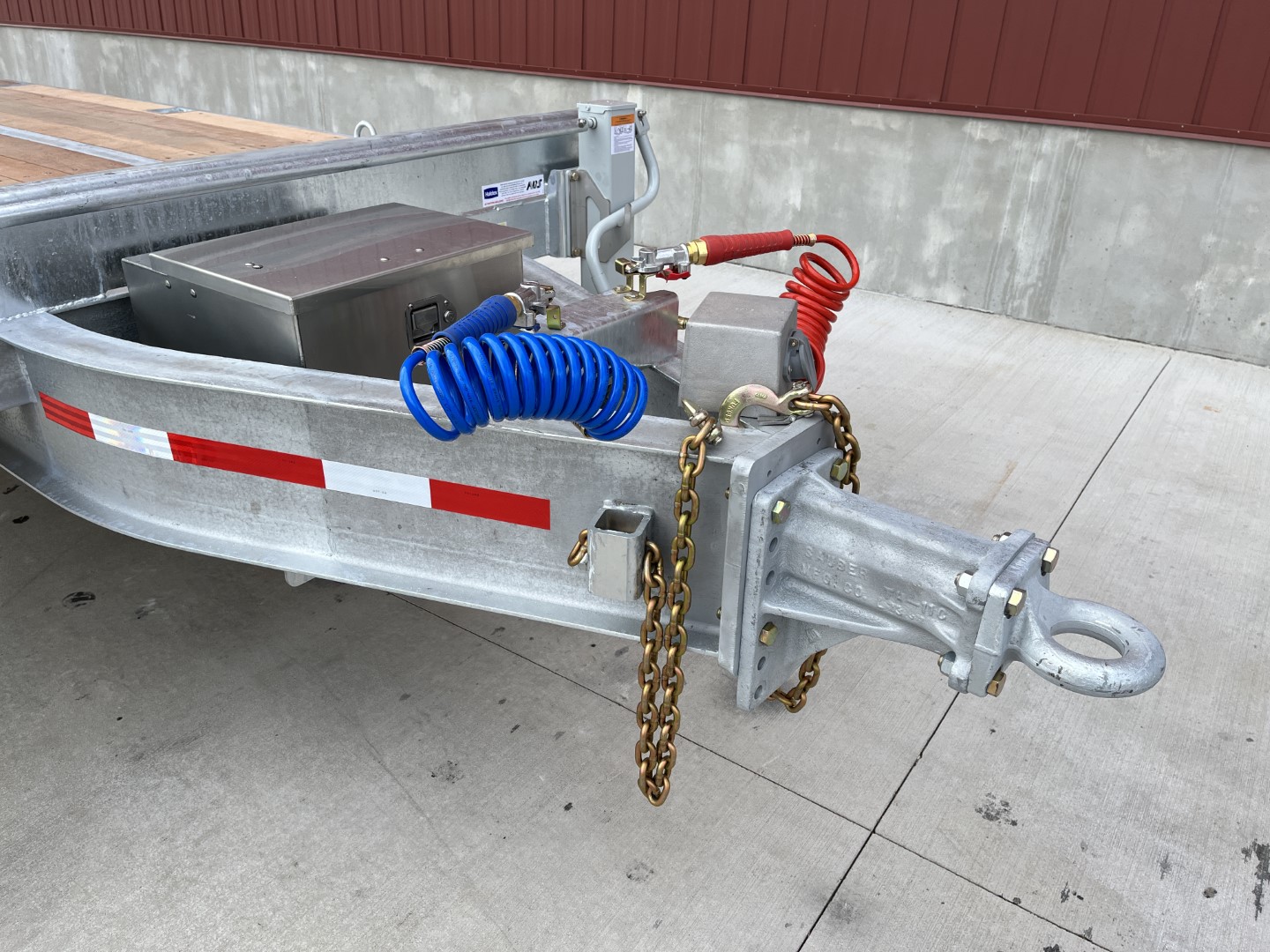

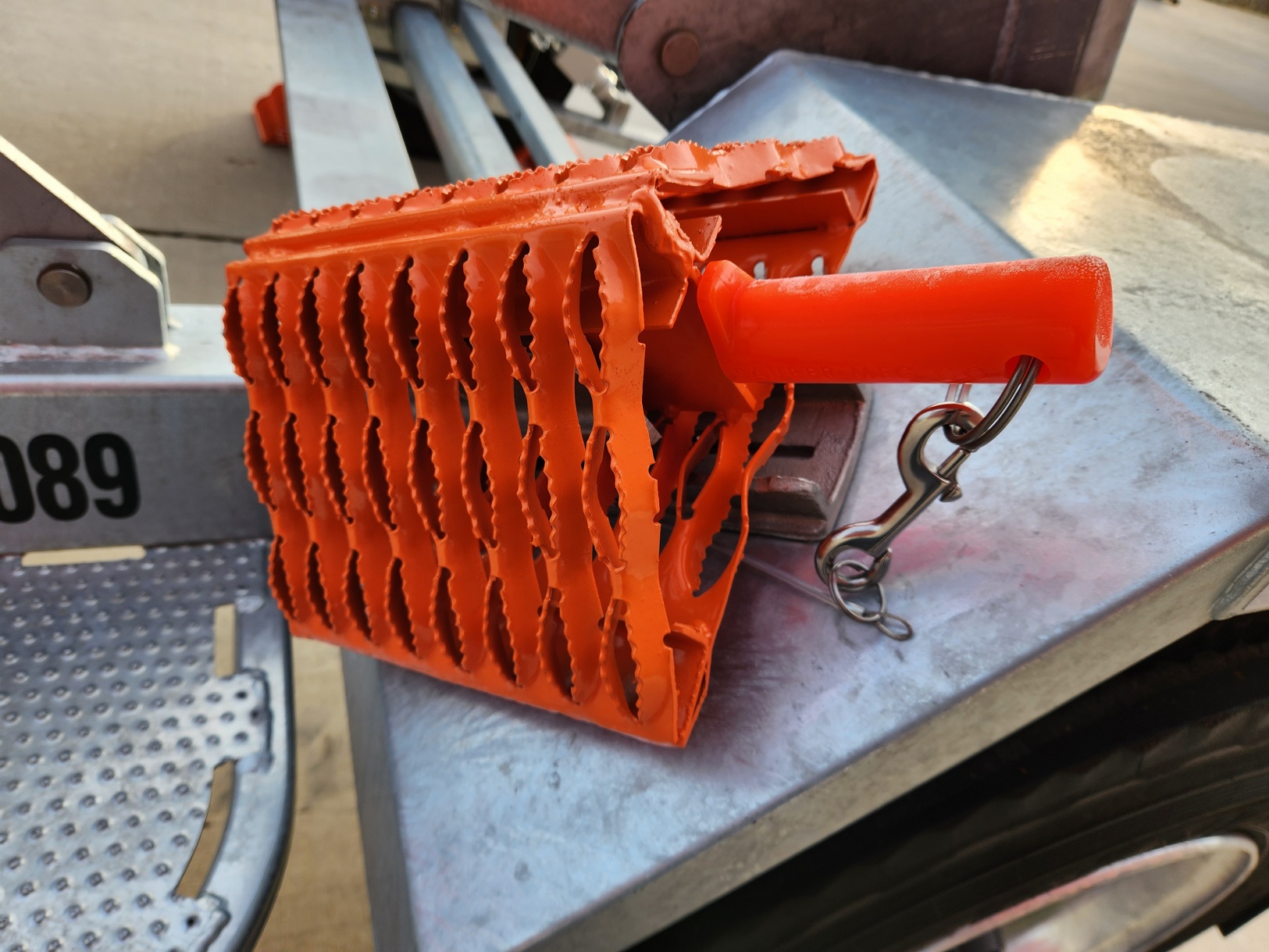

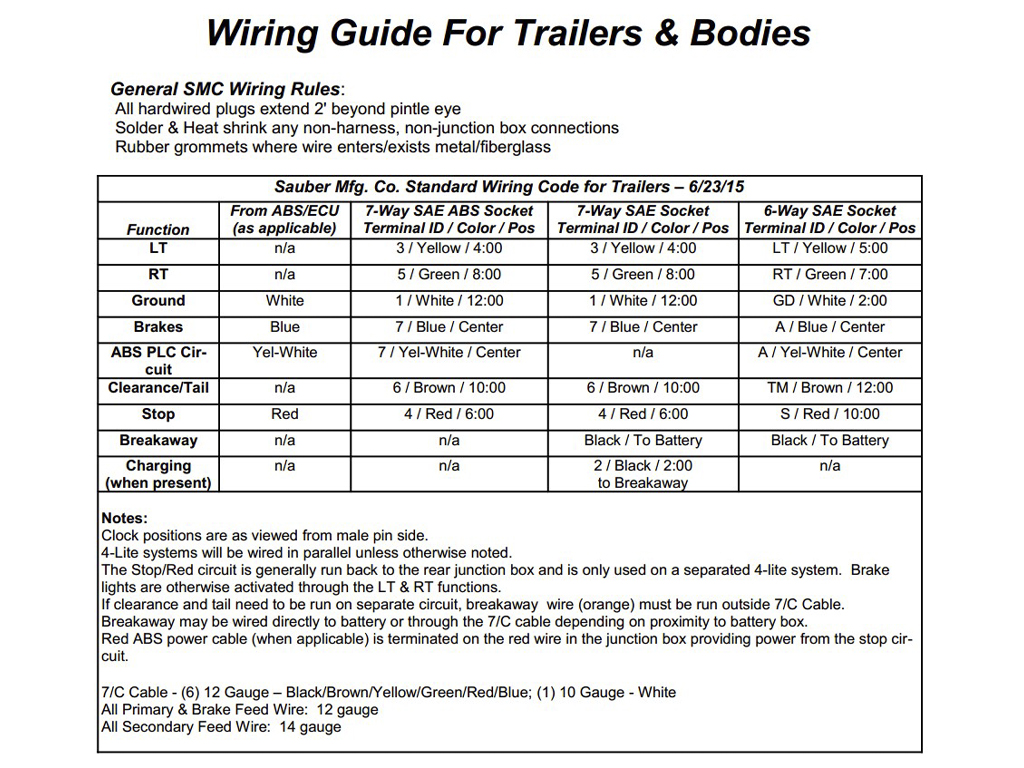

Equipment transport requires reliability and safety. This galvanized beavertail equipment trailer offers that plus extreme durability in heavy construction environments. Standard features include the galvanized finish, angelim decking, and low effort ramps. Outfit the trailer to meet your work. Choose storage and securement components for materials that must go with the trailer to ensure operators can work efficiently. Specify your beavertail equipment trailer with deck size and weight capacities required by your work. Solid model approval drawings provide confidence in the final design. Contact us to specify your trailer today.

Click here to see trailer specifications similar to the Model 1580-BT Galvanized Beavertail Equipment Trailer.

Capacity: 20600#

GVWR: 28200#

Deck: 19'L Flat Deck + 4'L Beavertail

Dimensions: 30'L x 102"W