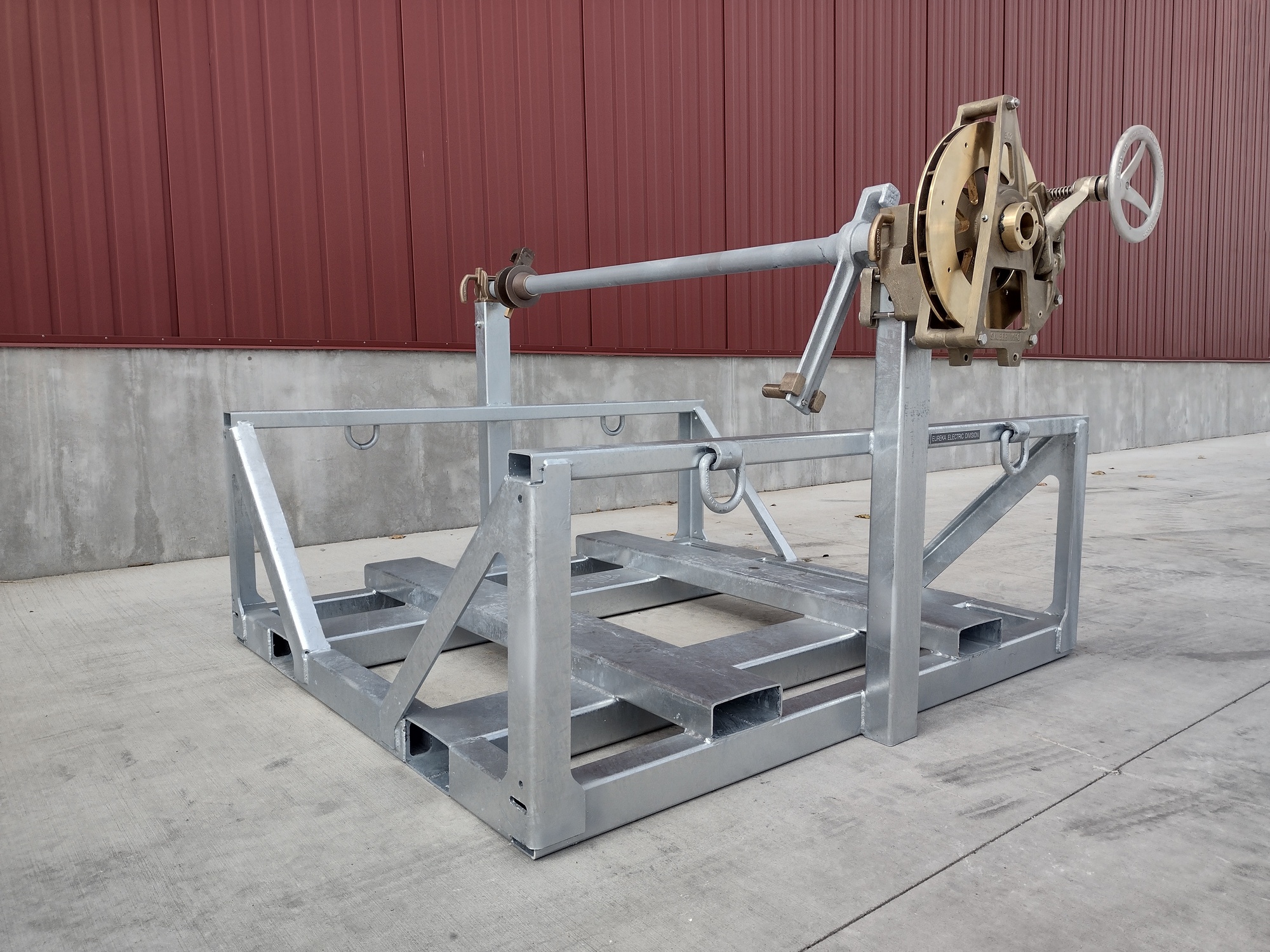

Tiltbed Trailer

Model 1580-TB

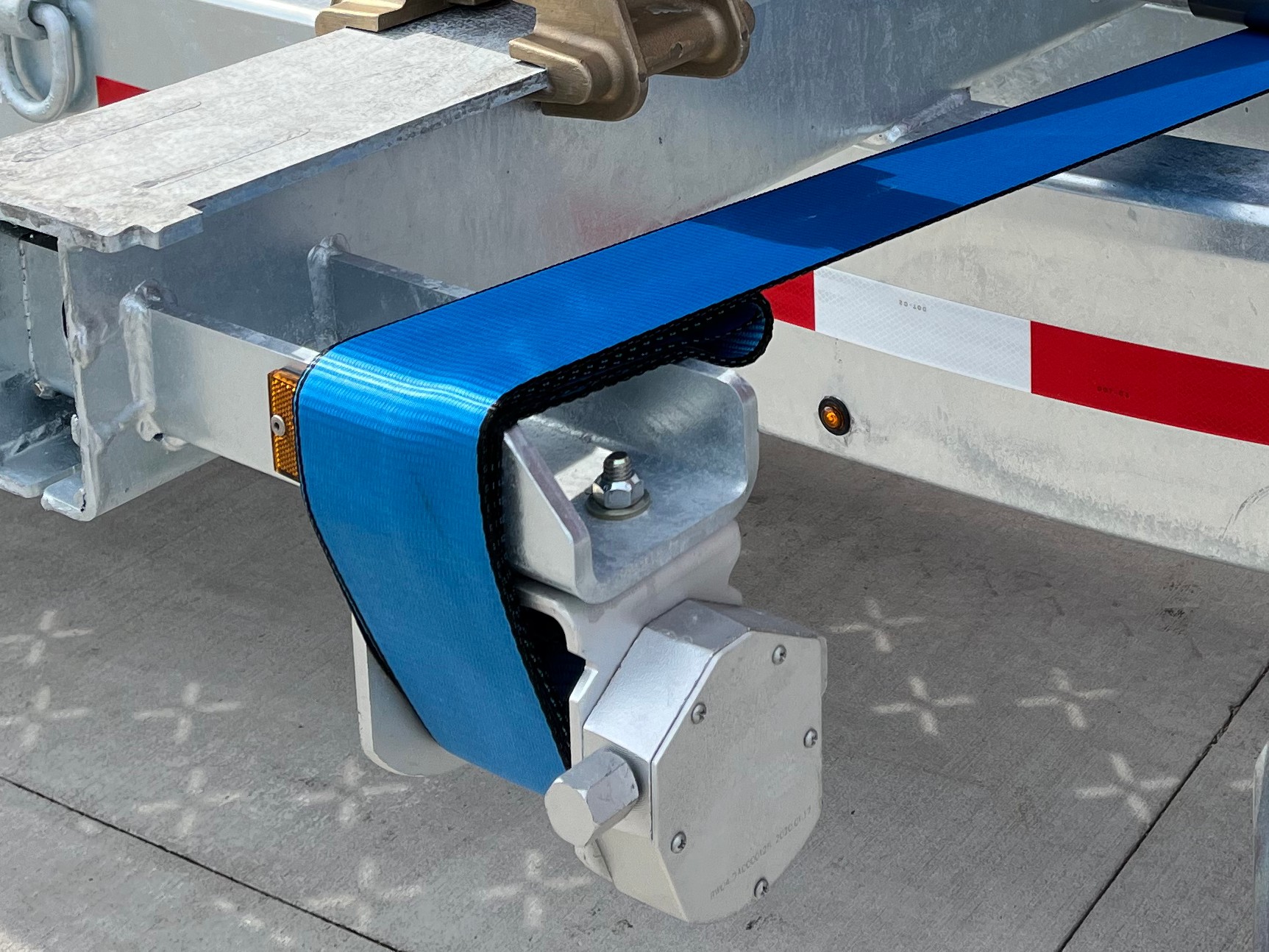

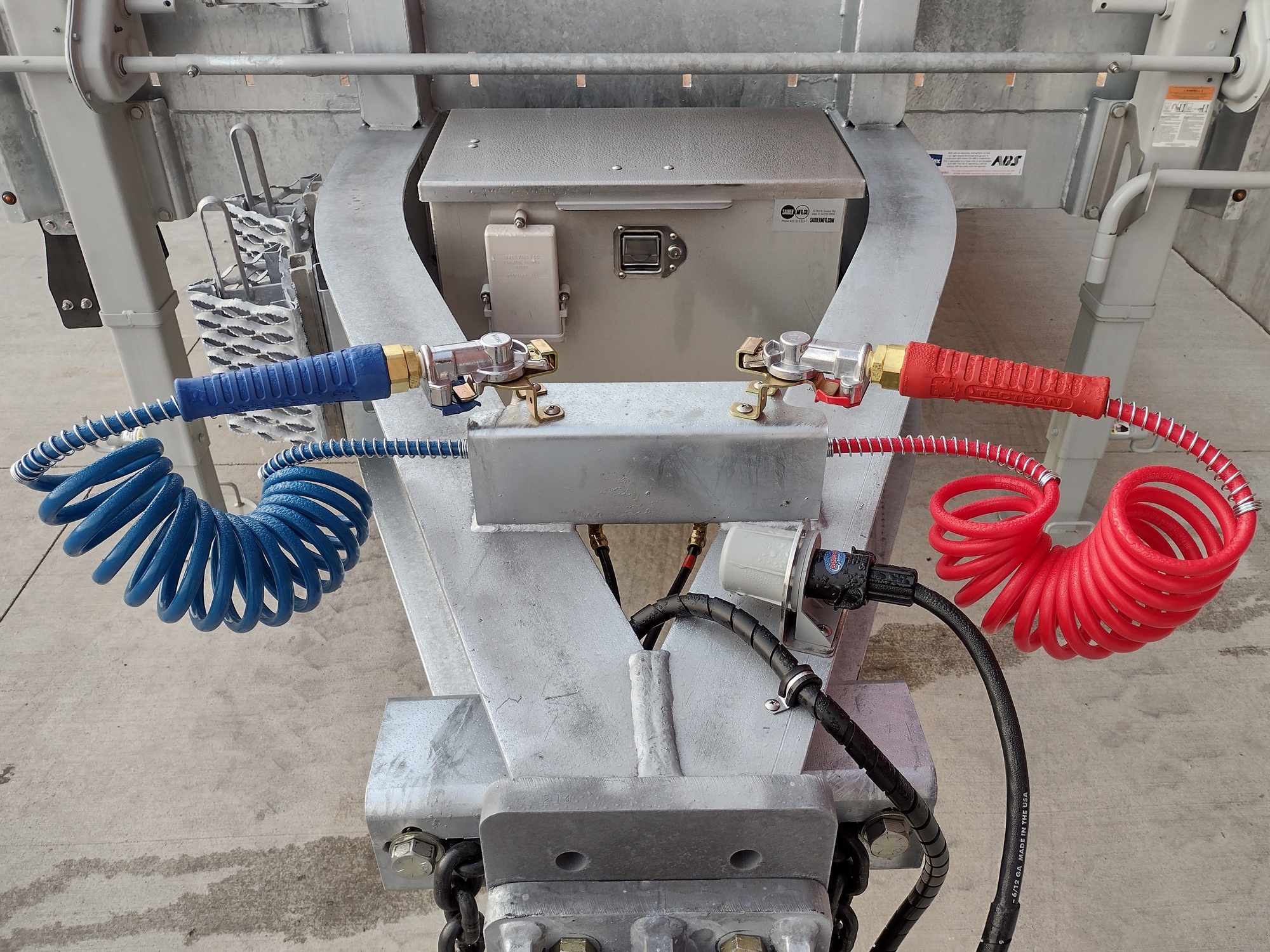

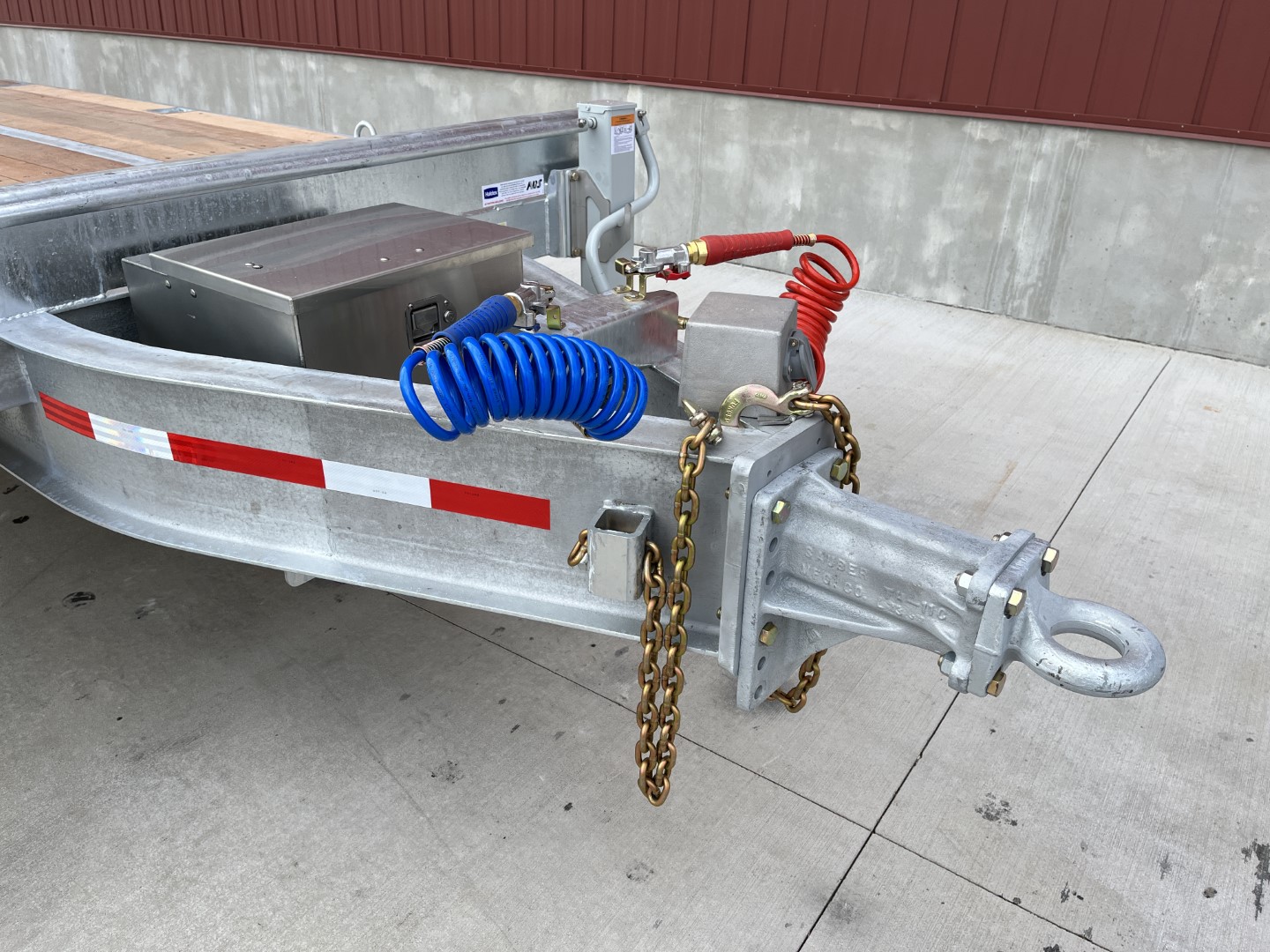

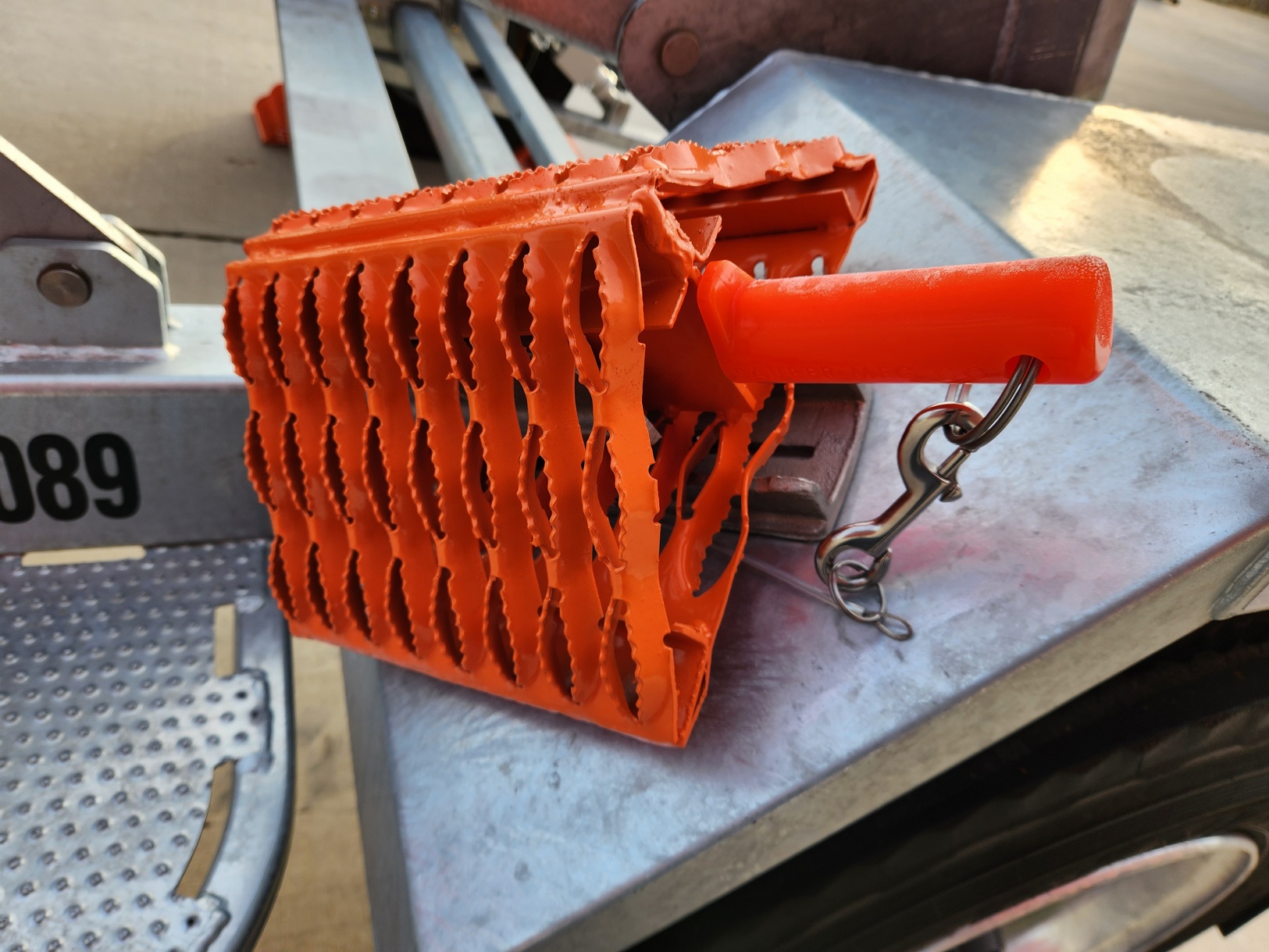

With high capacity, operator friendly features and proven durability, this equipment trailer is ready for utility work. Standard features such as galvanized finish and angelim decking are coupled with a Hutch suspension and a 14.6 degree loading angle. Standard operator access steps with three-point contact and stainless-steel toolbox add to your crew’s safety and efficiency. This unit is designed for productivity and low lifecycle cost.

Capacity: 17400 lbs

Deck: 20' x 96"

Dimensions: 28'L x 96"W, 33" Deck Height

Axle: (2) 12000 lbs

Brakes: 12.25" x 5", Air

Suspension: Hutch # H-900 Single, Point - 36,000 lbs

GVWR: 28200 lbs

Tires: (8) 235/80R16(E)

Rims: (8) 6.00 x 16, Disc