Telescoping Pipe Trailer

Model 1590

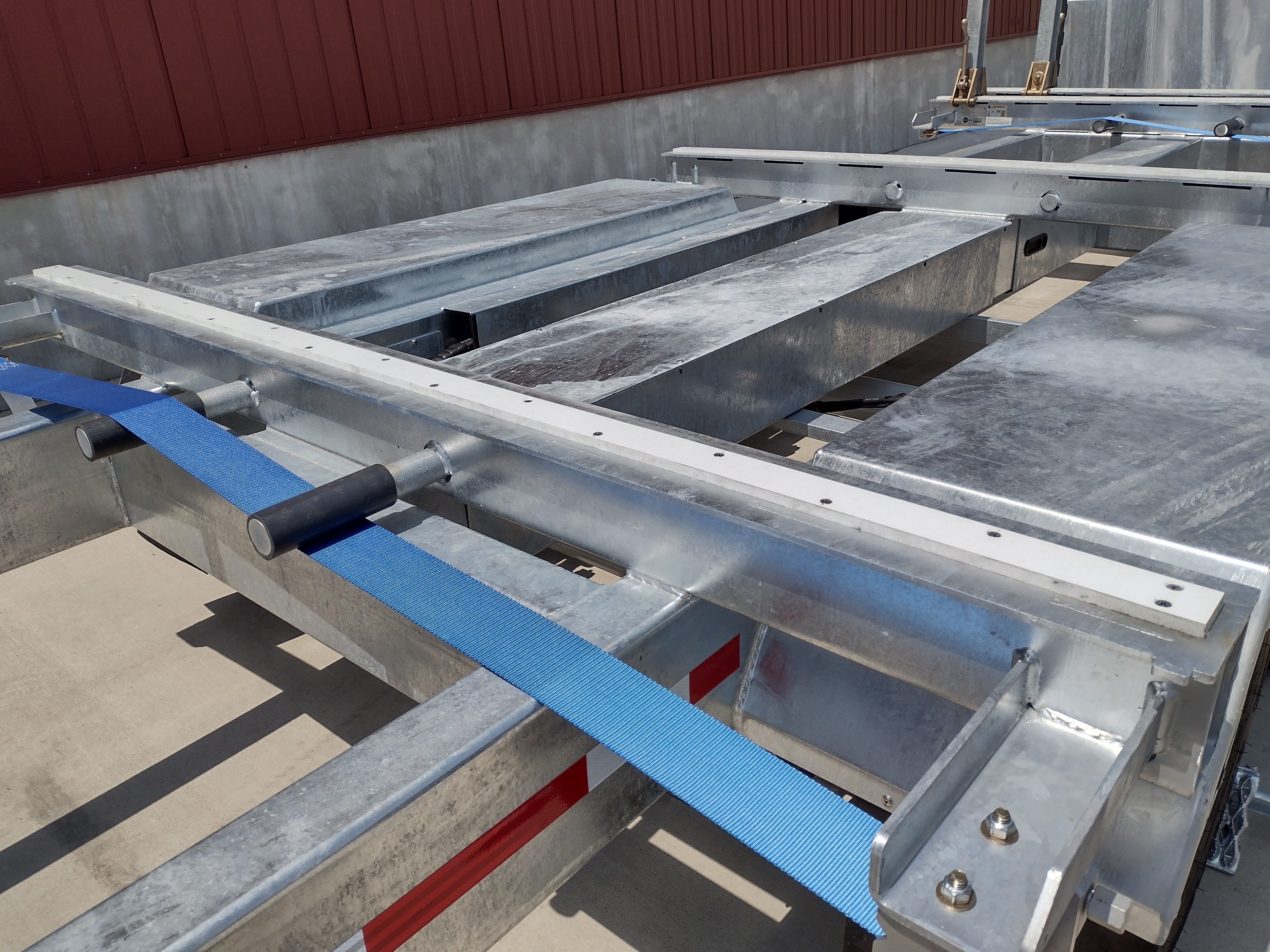

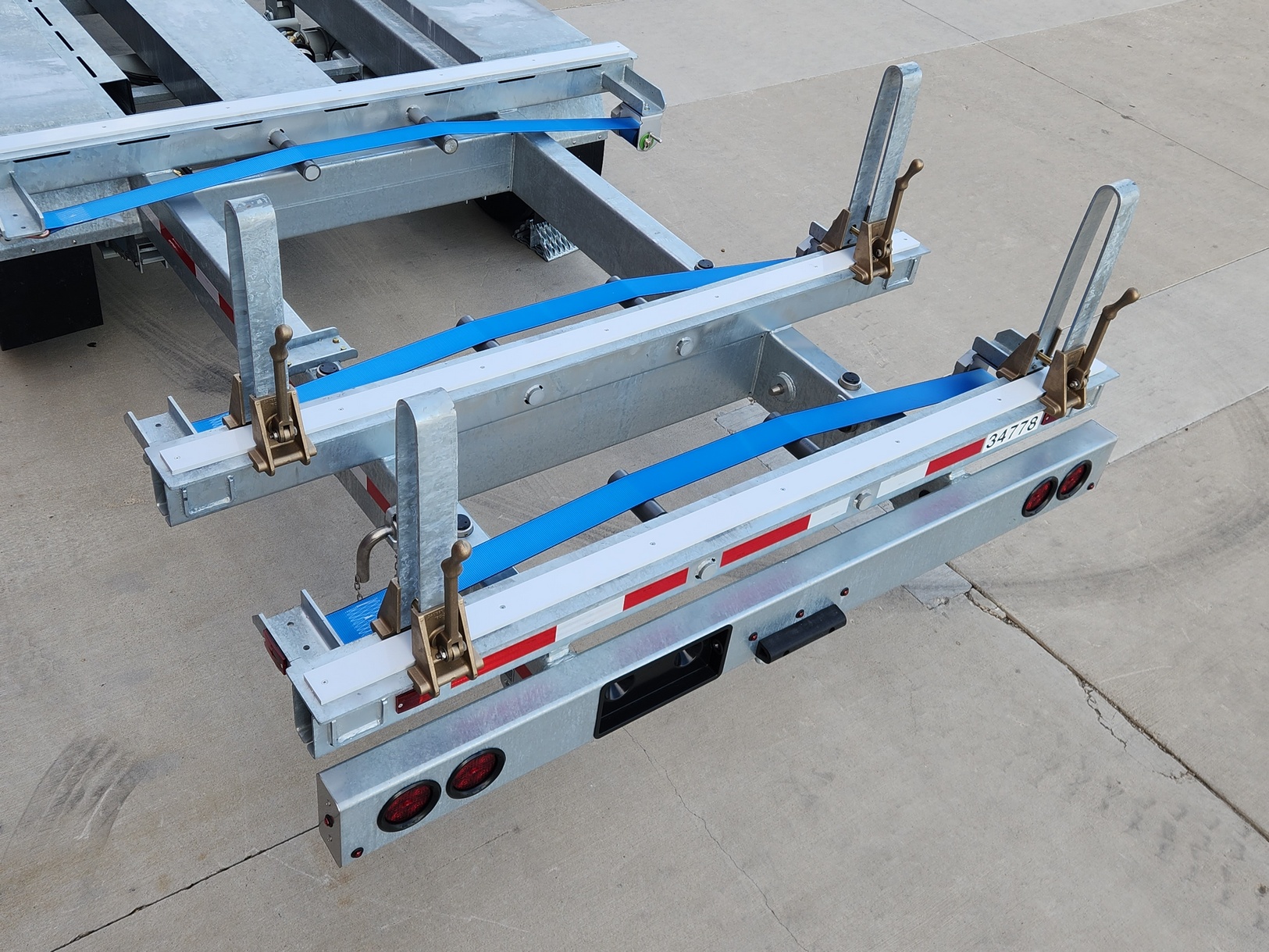

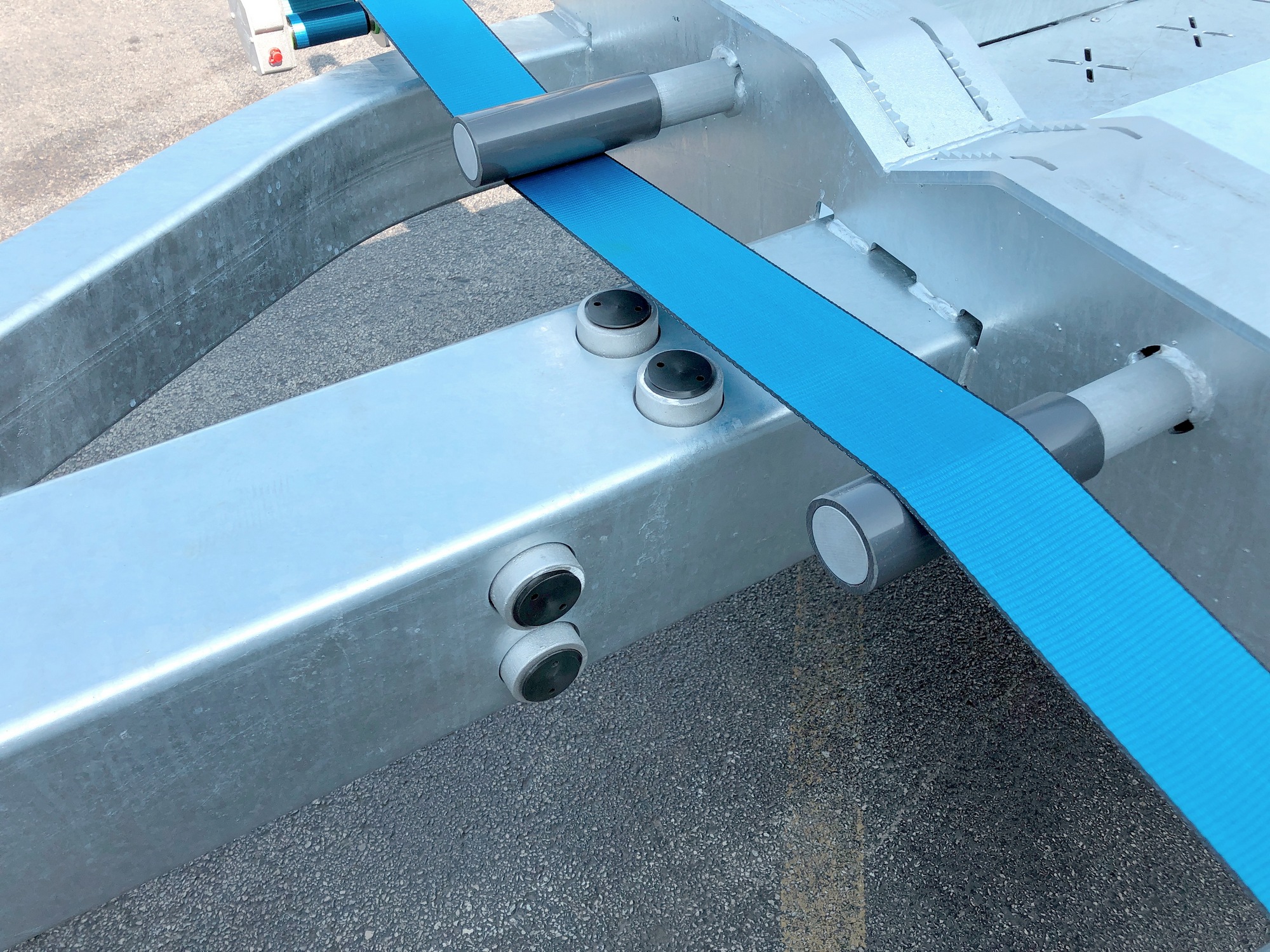

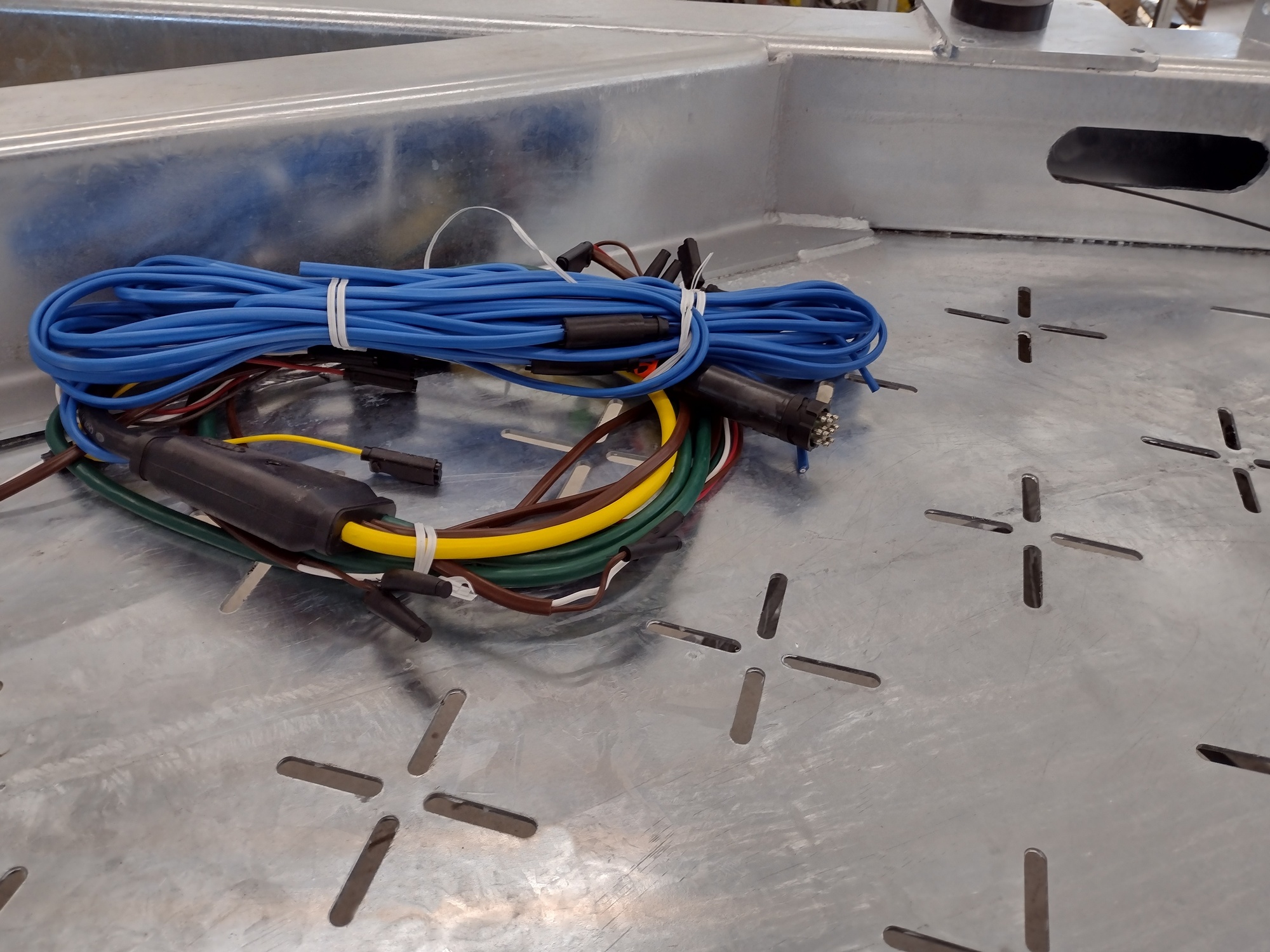

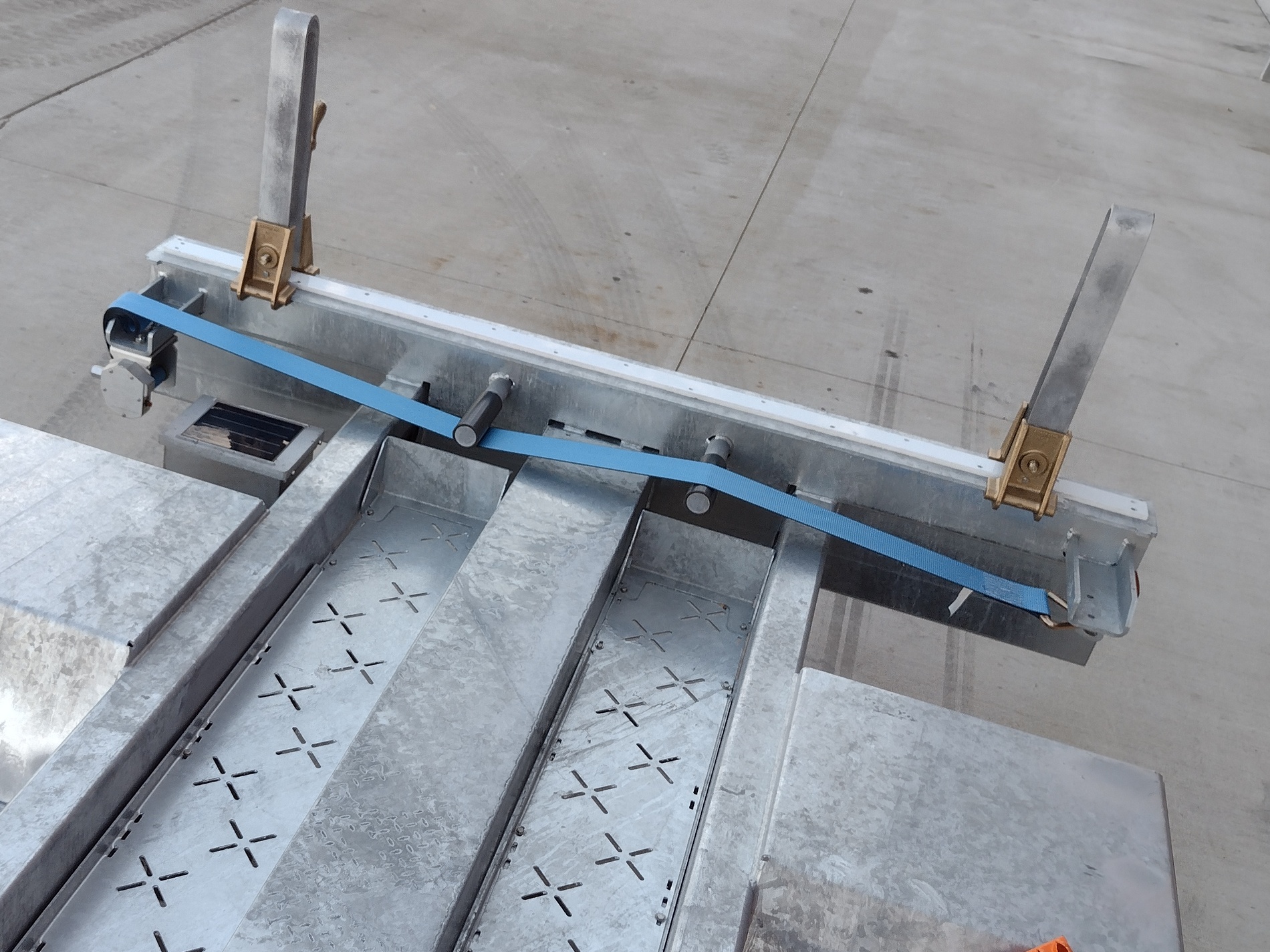

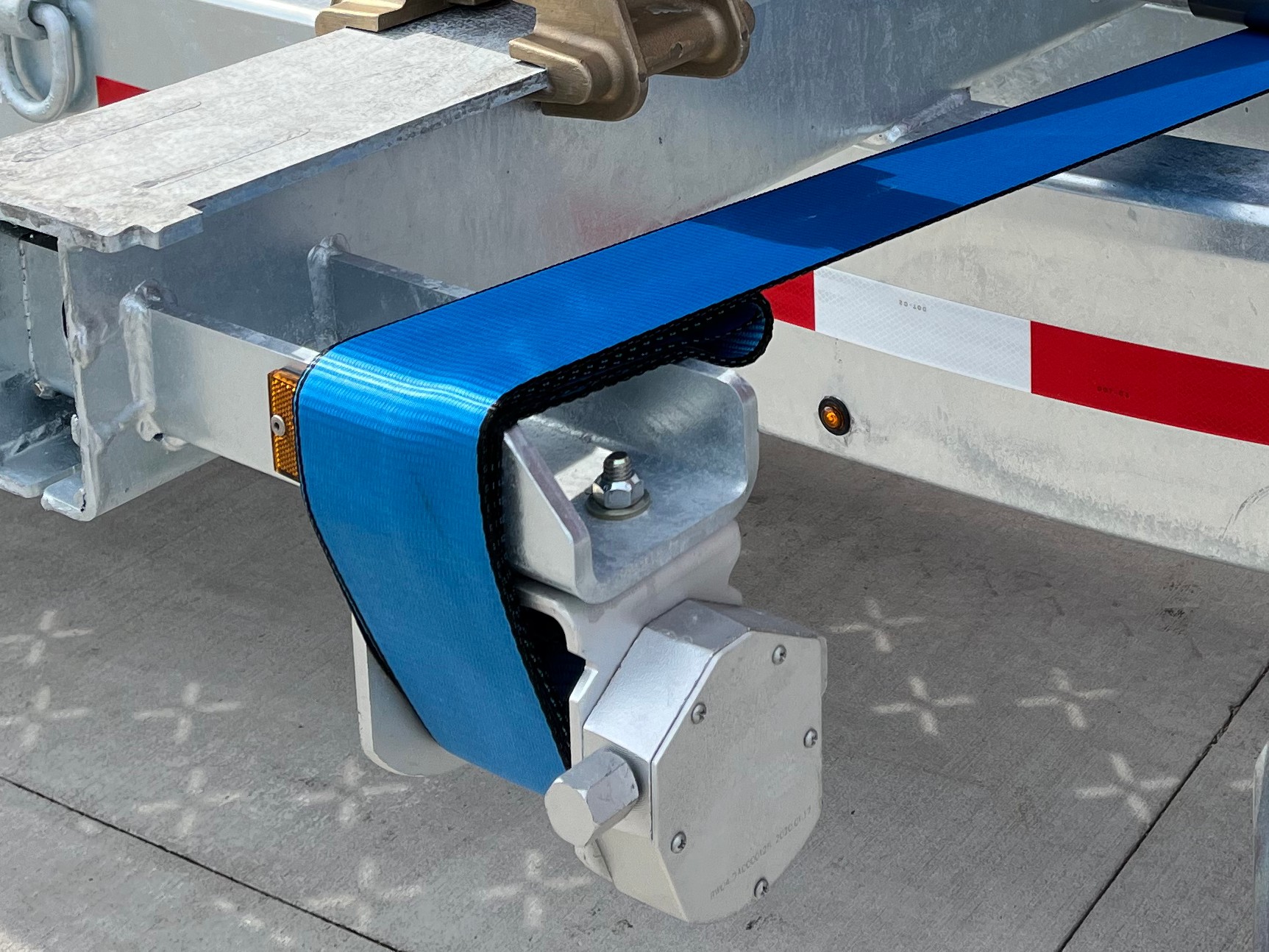

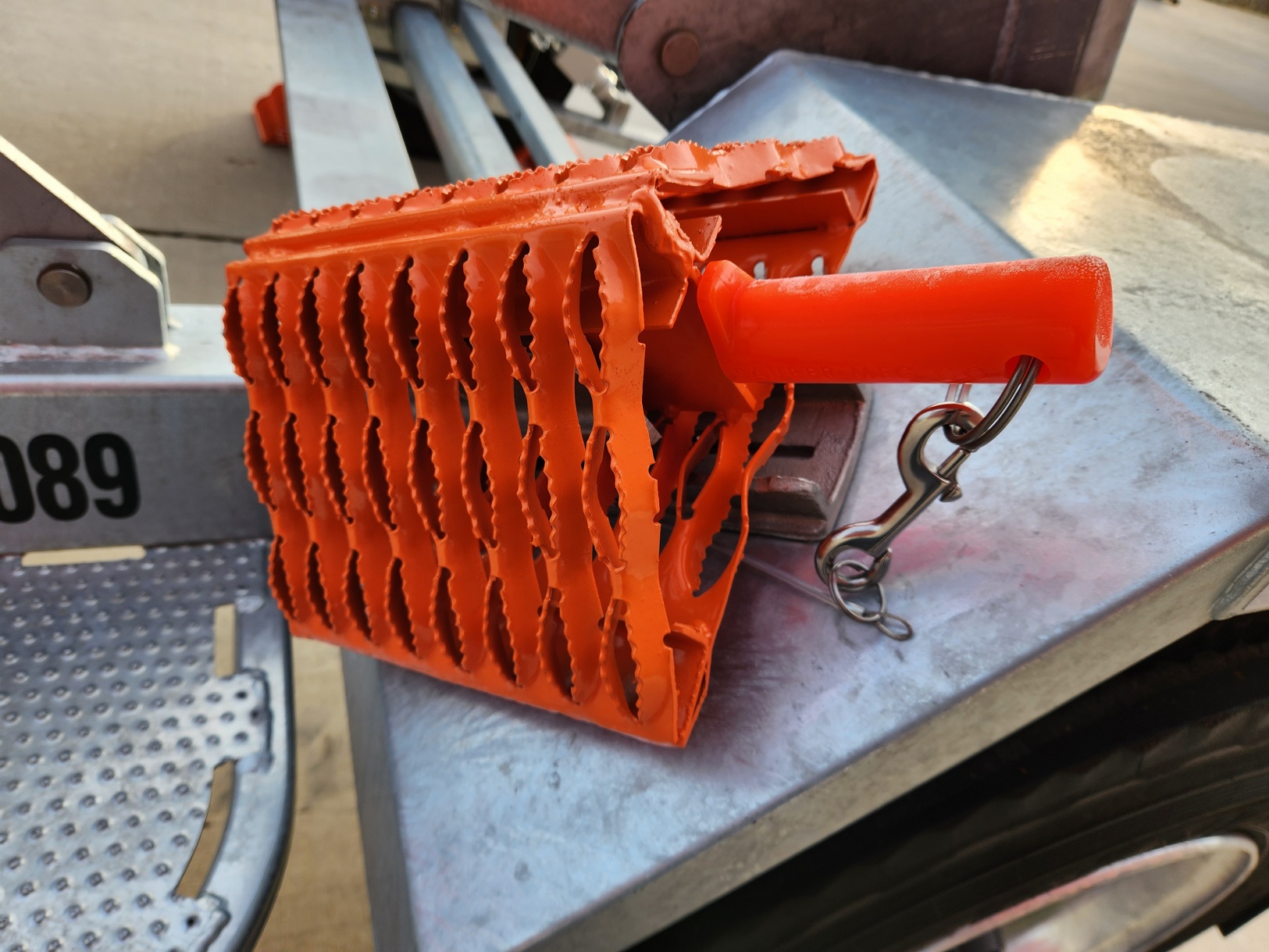

Get reliable hauling for your plastic or steel stick pipe from the Model 1590 Telescoping Pipe Trailer. Front and rear extension to provide the support required by the load and self-locking worm gear drive winch binders provide for easy securement. Plus, a standard bulkhead ensures a safe and secure load. Customize the telescoping pipe trailer to meet your capacity, loading method, and job site requirements. And with our standard features like tube construction, galvanized finish and sectionalized, hidden wiring harness it will handle utility work for years to come.

Click here to view similar equipment.

Capacity: 14910#

GVWR: 21150#

Dimensions: 46'L x 96"W