Construction and Maintenance Trailer

Model 1592

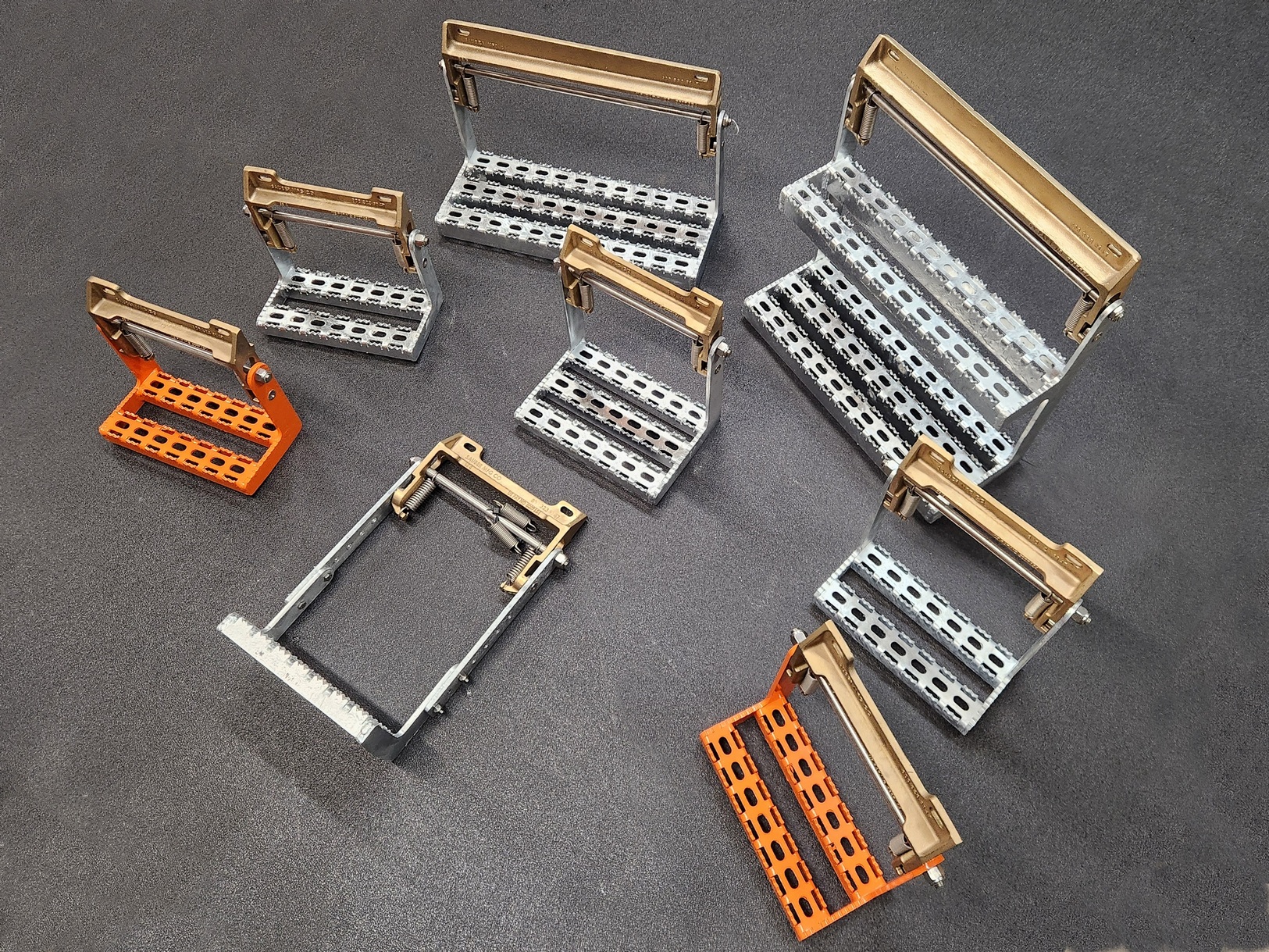

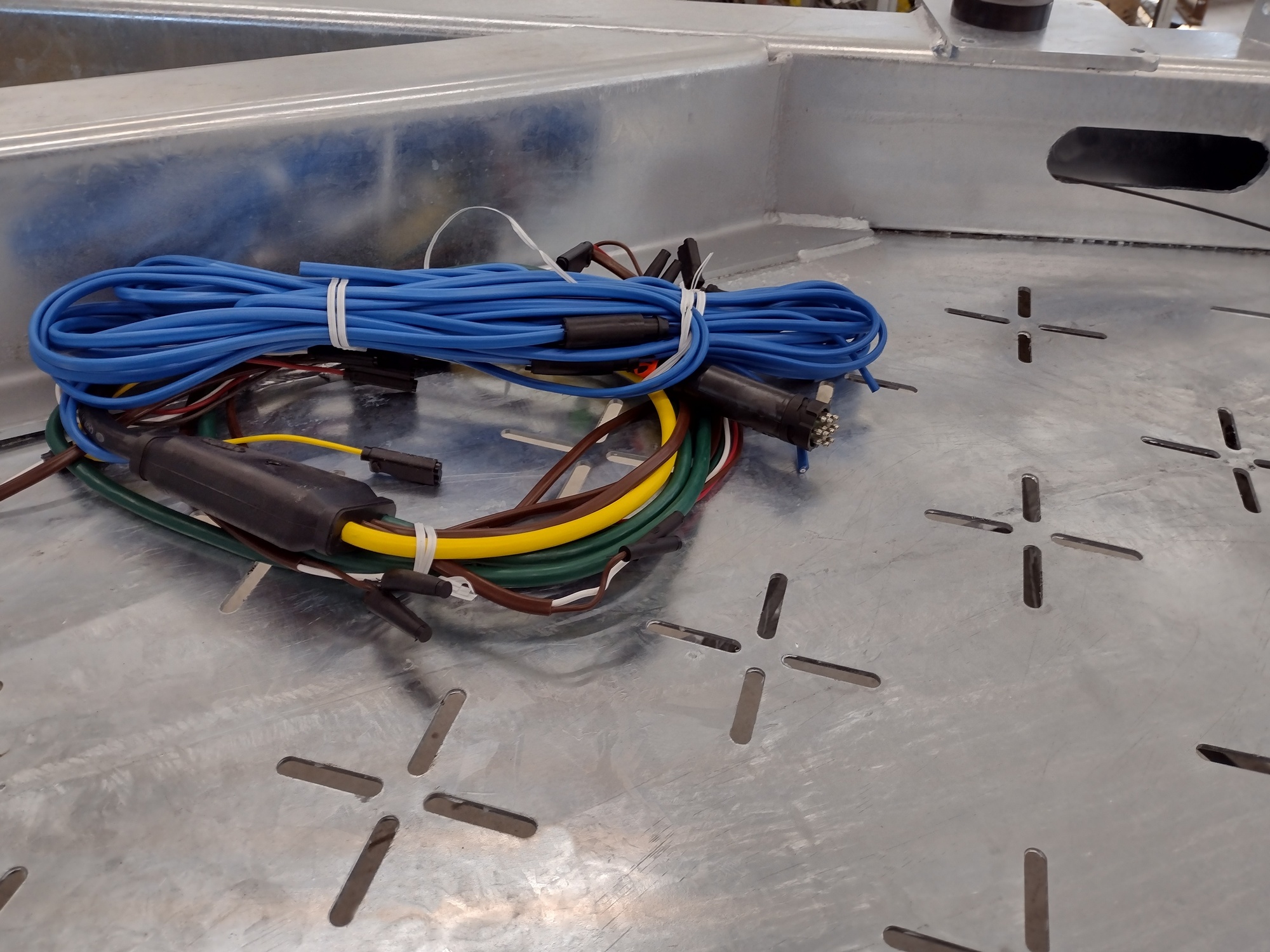

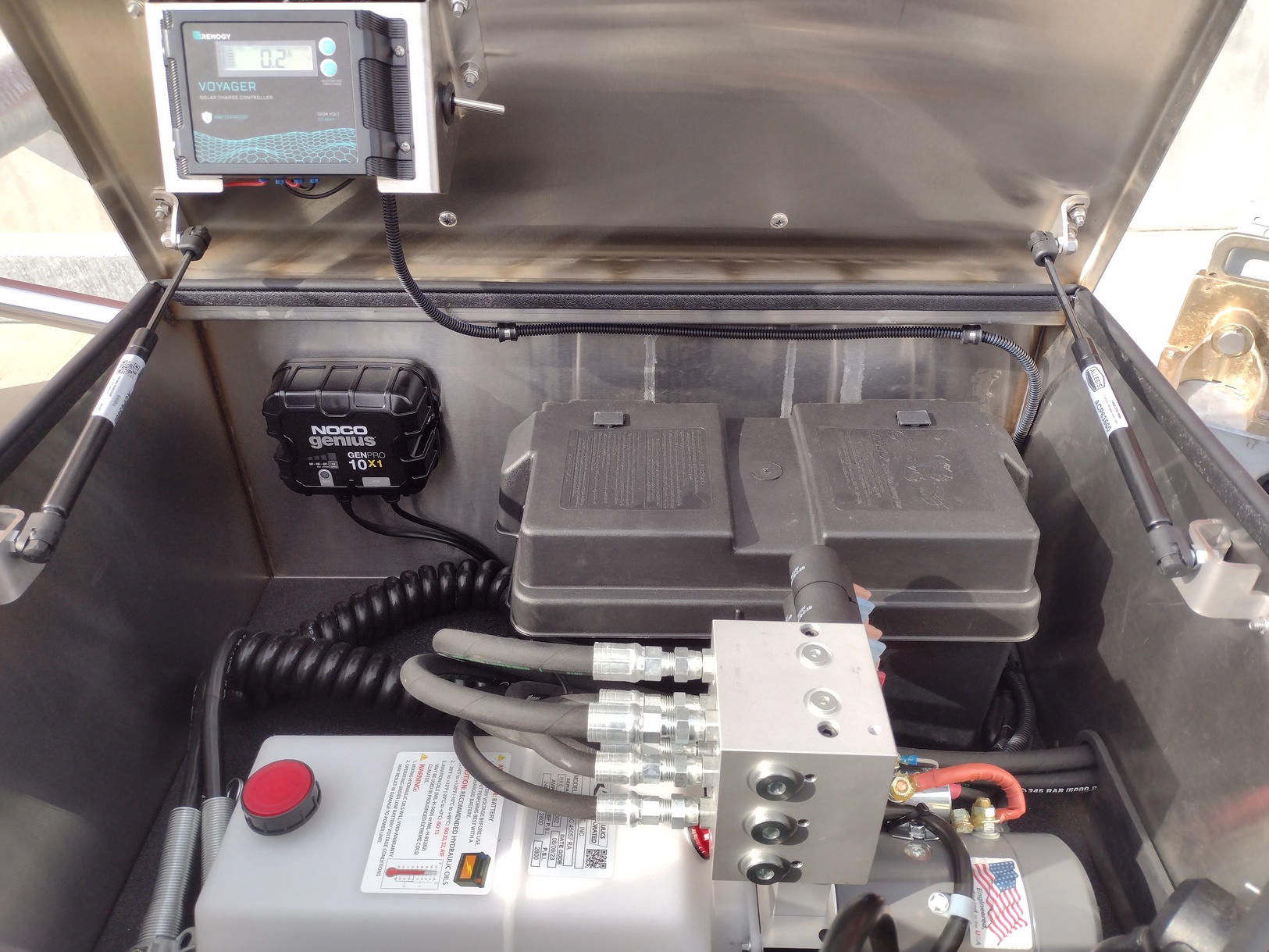

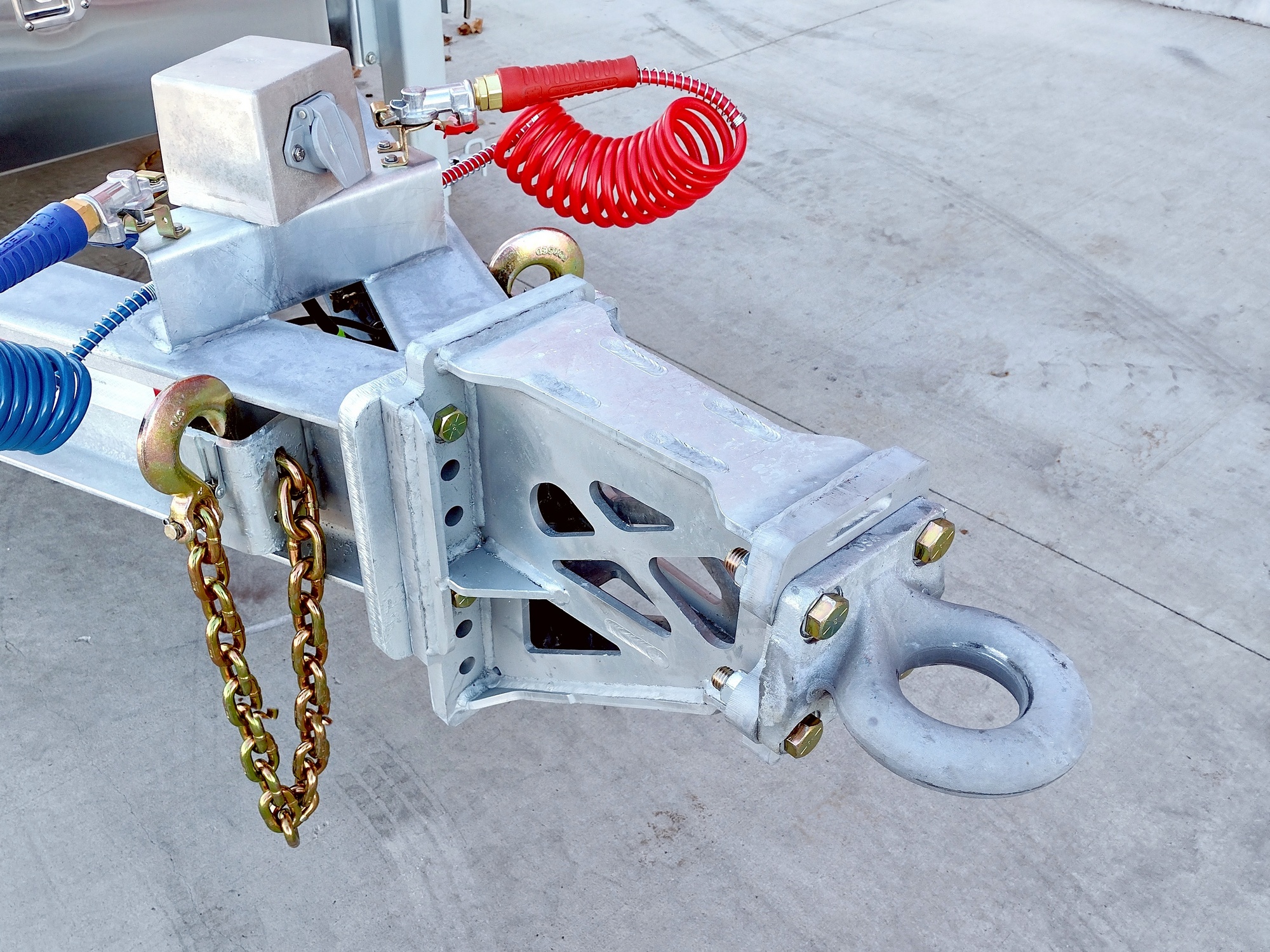

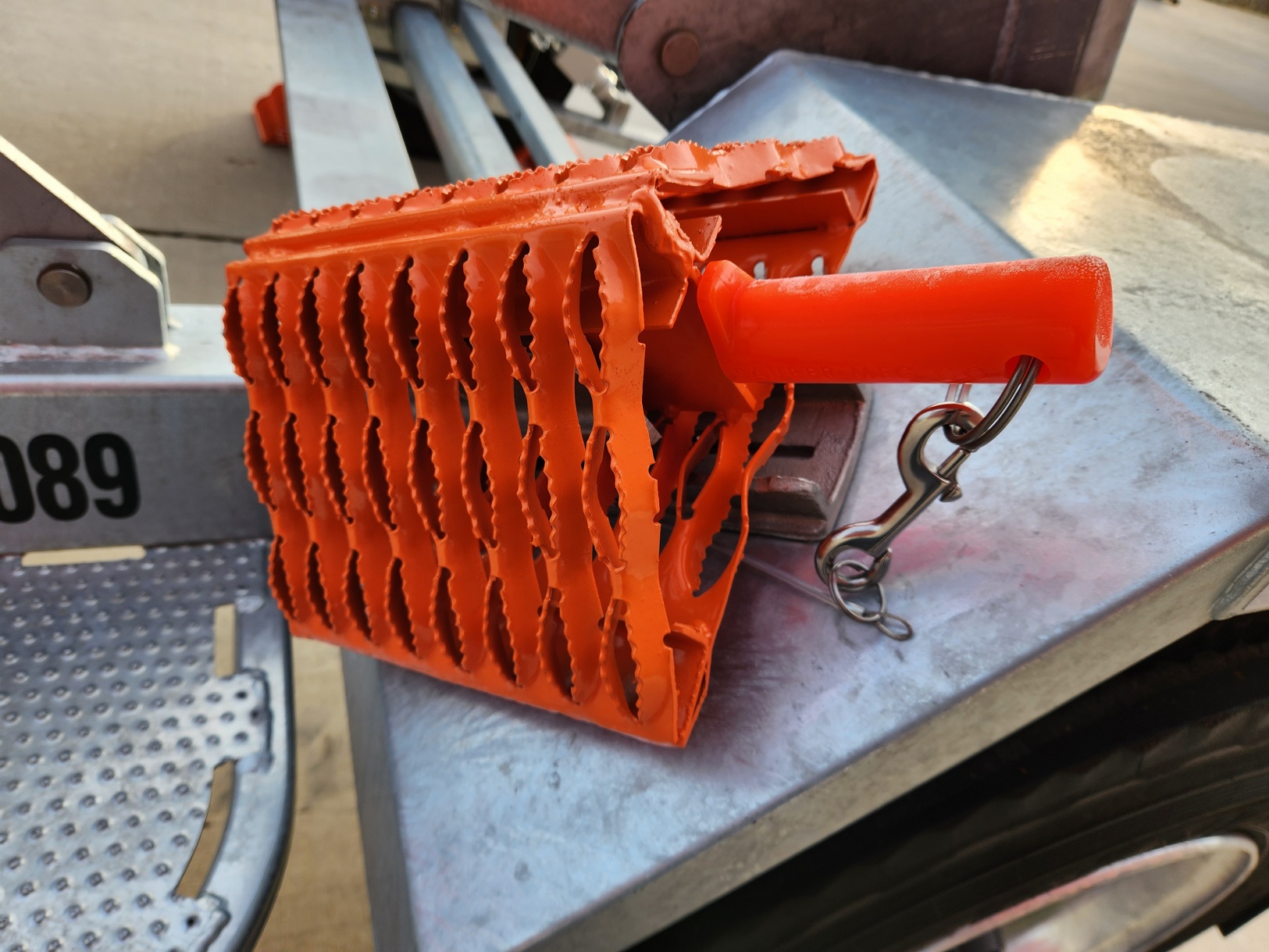

Inventory your materials right on the trailer and eliminate extra trips. The Model 1592 Construction and Maintenance Trailer carries your tools and materials right to the job site. The modular aluminum structure, stainless steel doors and integrated flasher system make a compelling case for this productivity enhancing trailer. Modify the trailer to meet your work methods and capacity requirements with available tandem axles, enclosures, onboard power and additional box configurations. Sauber Mfg. Co.’s standard components and designs ensure your construction and maintenance trailer will last for decades.

Click here to view similar equipment.

Capacity: 4000#

GVWR: 8300#

Cargo: 112" x 56"

Dimensions: 16'L x 90"W