Oil Filtration Trailer

Model 1594

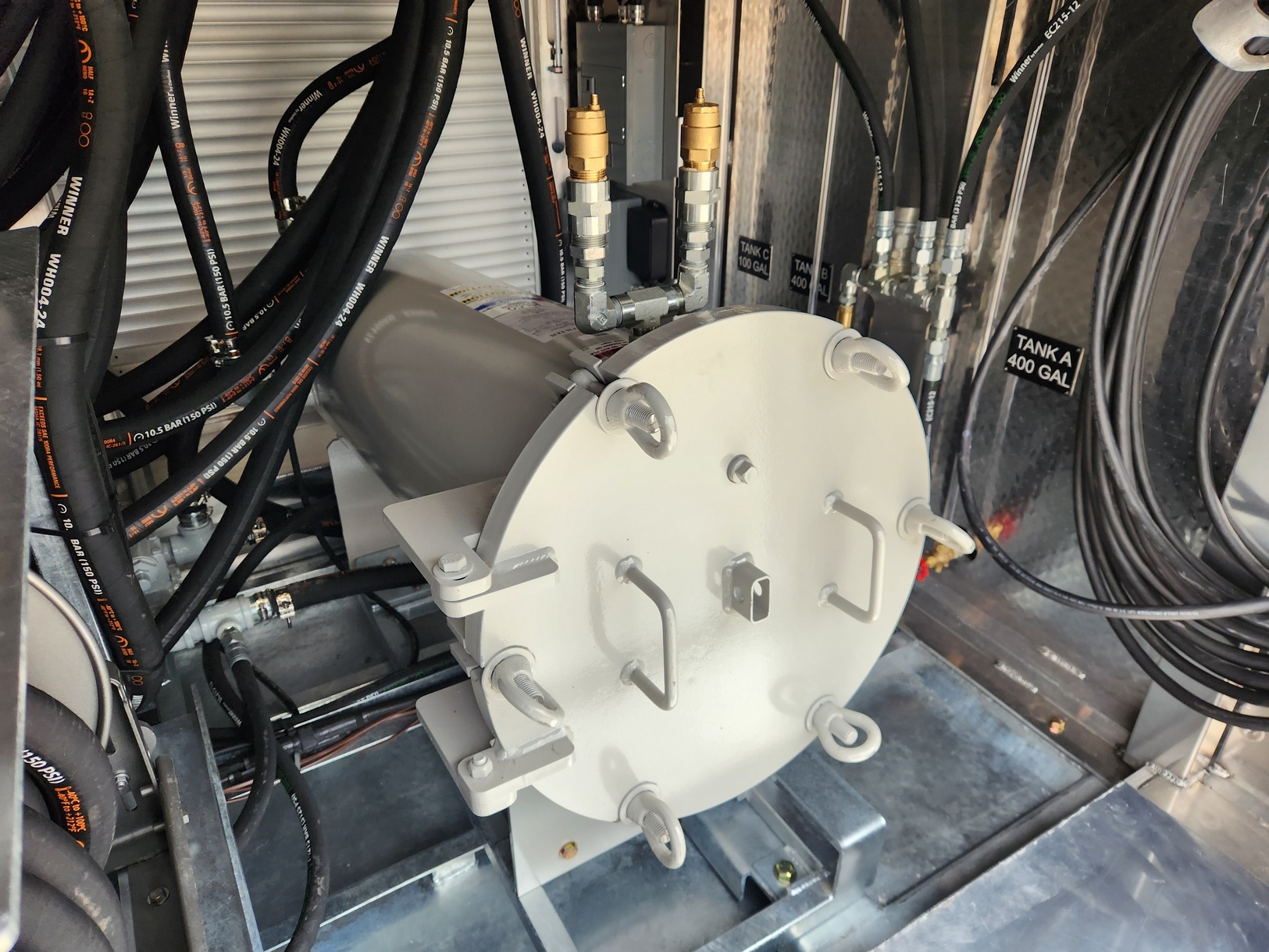

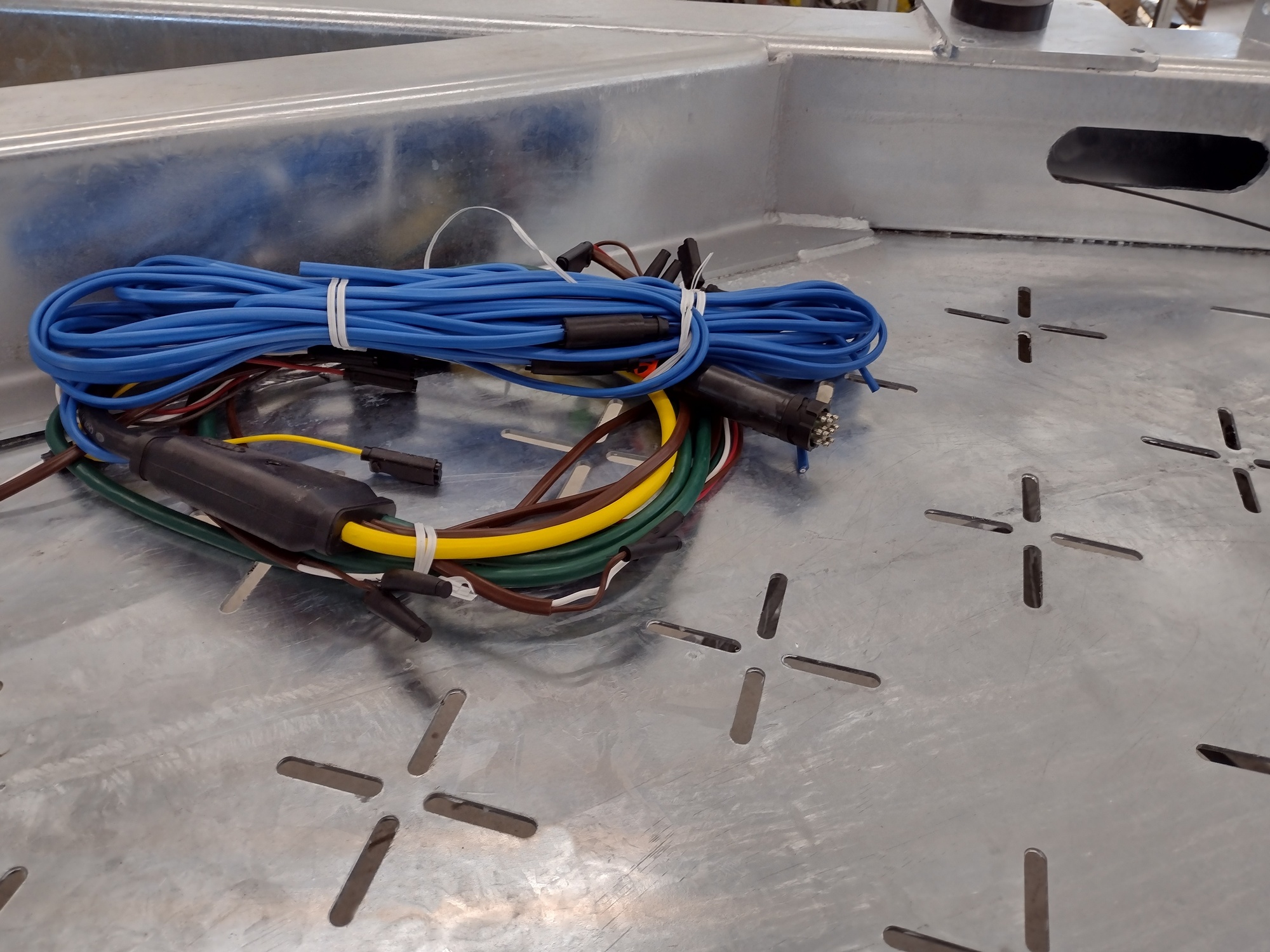

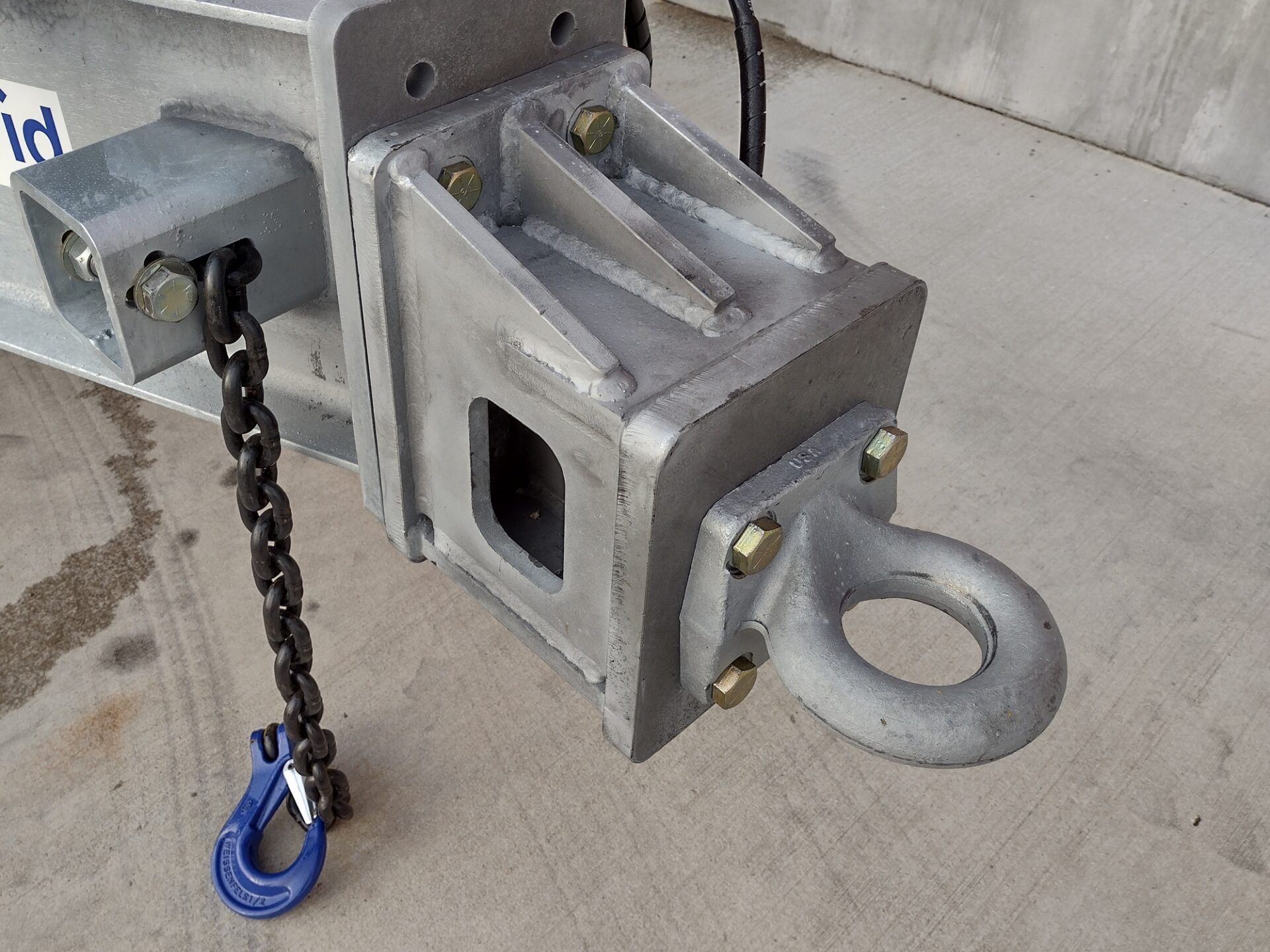

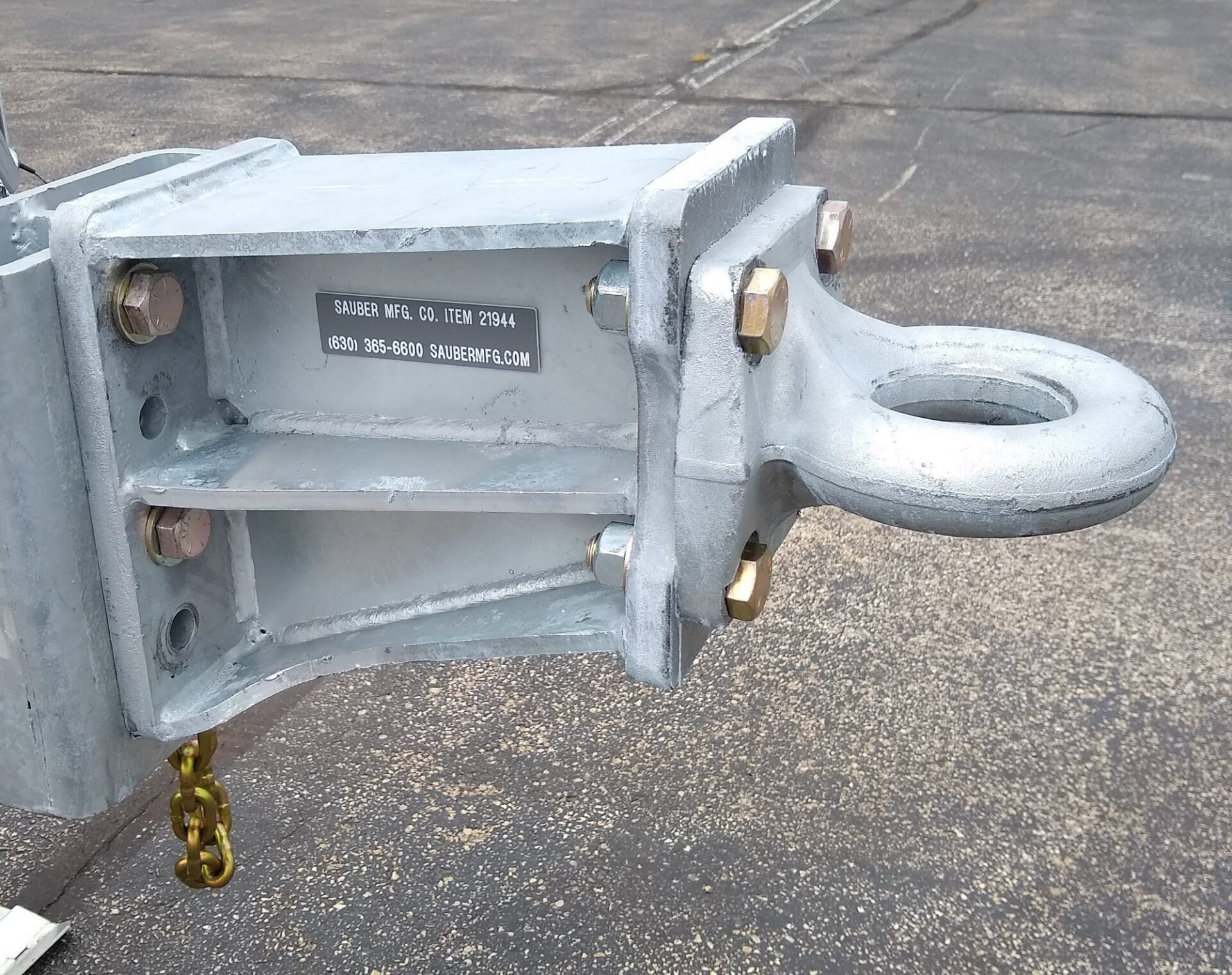

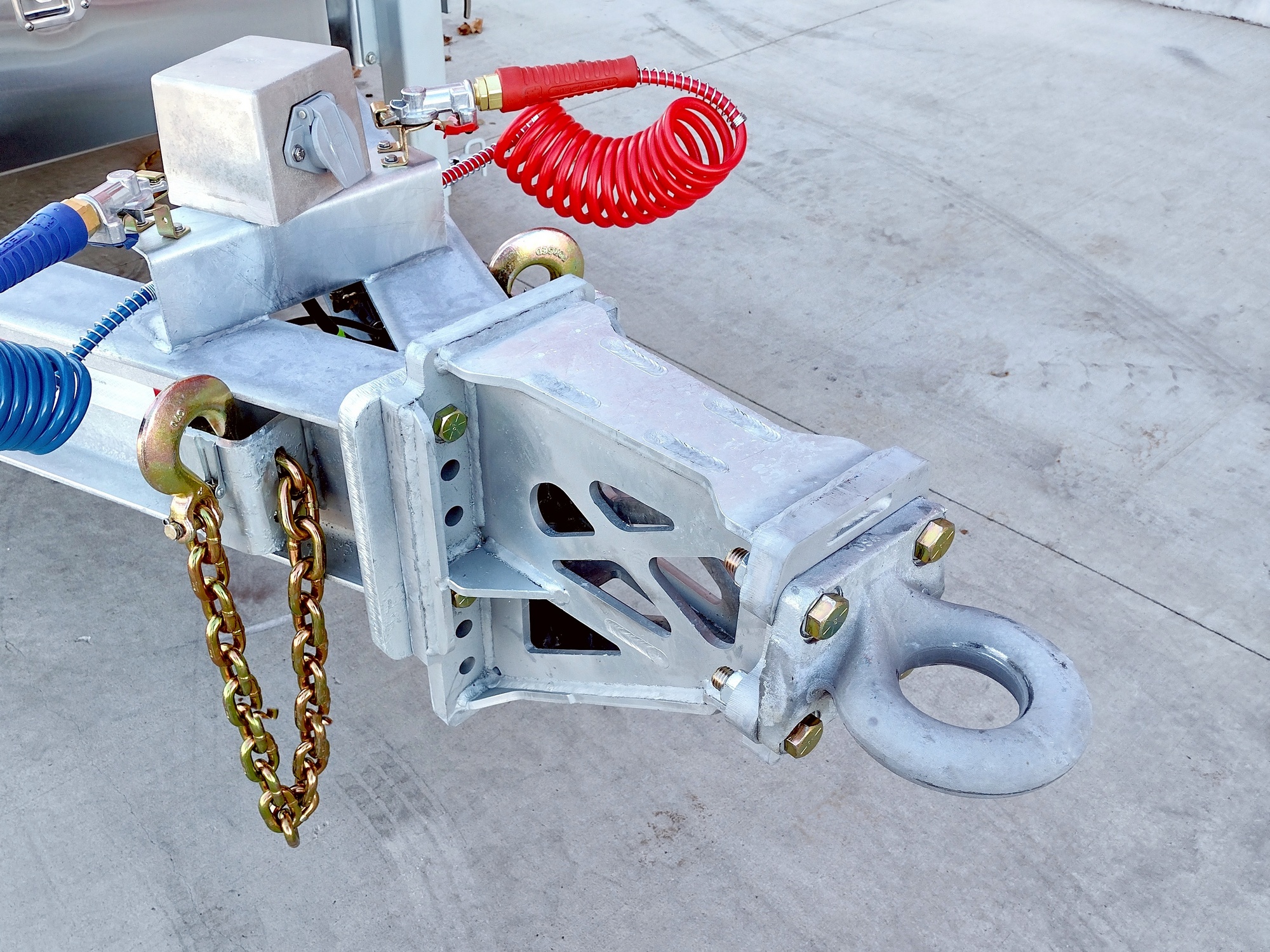

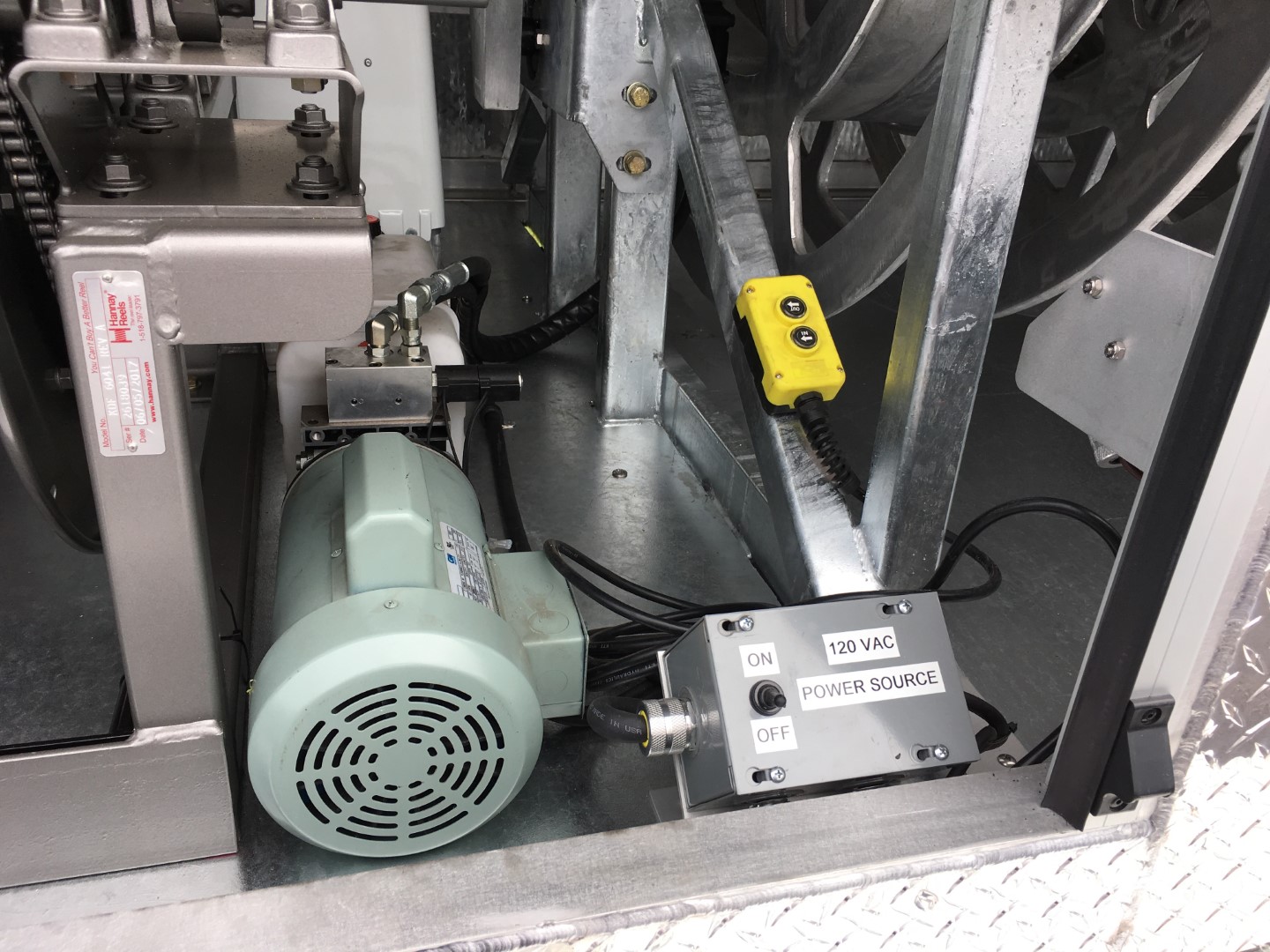

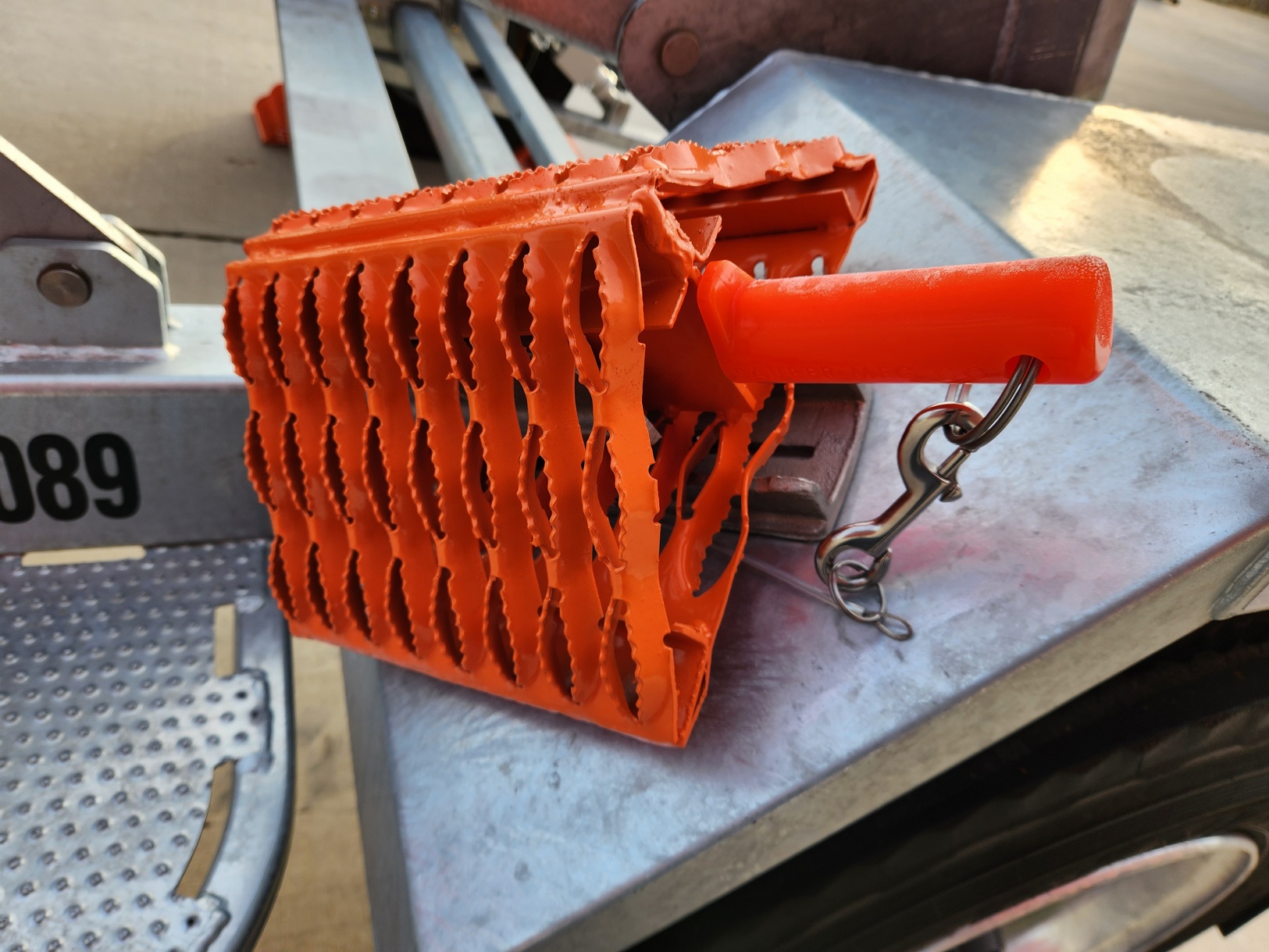

Configure your oil filtration trailer to your systems requirements and keep our simple to use EZ-Path controls. Simply choose the location and functions for the present task. With work area oil sump, hose reels, and available high oil shut off, you won’t waste time on your clean up phase. Onboard testing is available with integrated meters and 120 VAC outlets for your gear. You’ll rely on our oil filtration trailer for years thanks to the standard stainless-steel tank, aluminum enclosure, aluminum roll up doors and galvanized trailer frame. Contact us to review your requirements; you’ll be glad you did.

Click here to view similar equipment.

Capacity: 9550#

GVWR: 17750#

Dimensions: 19'L x 90"W