Pole Trailer

Model 1595

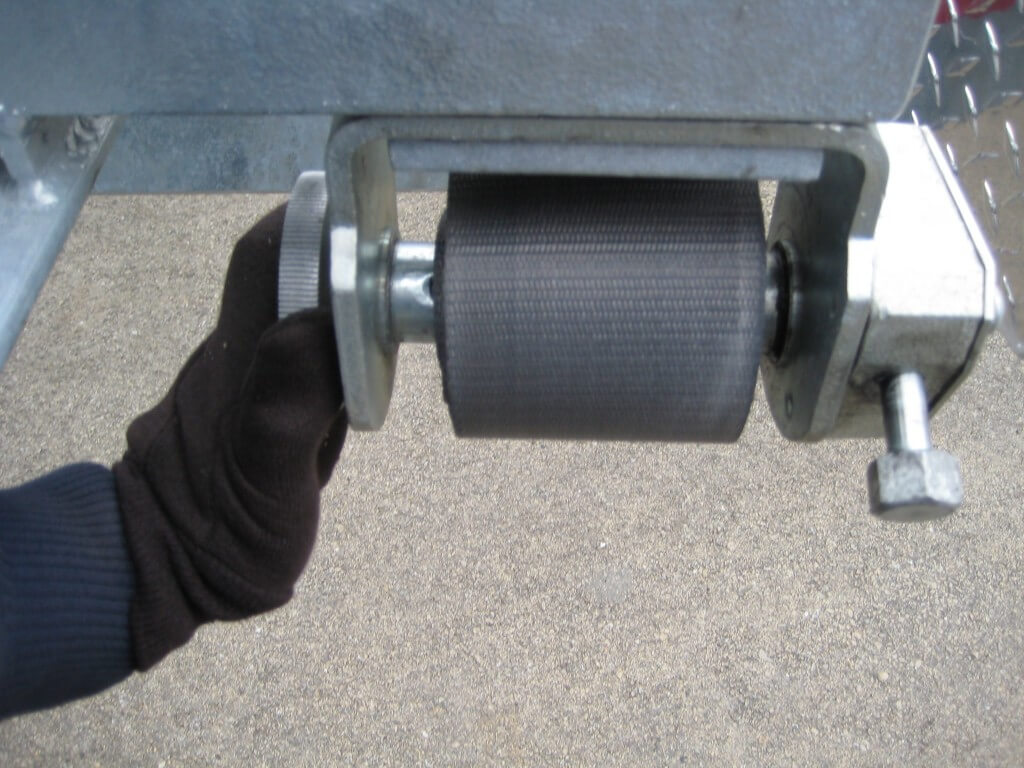

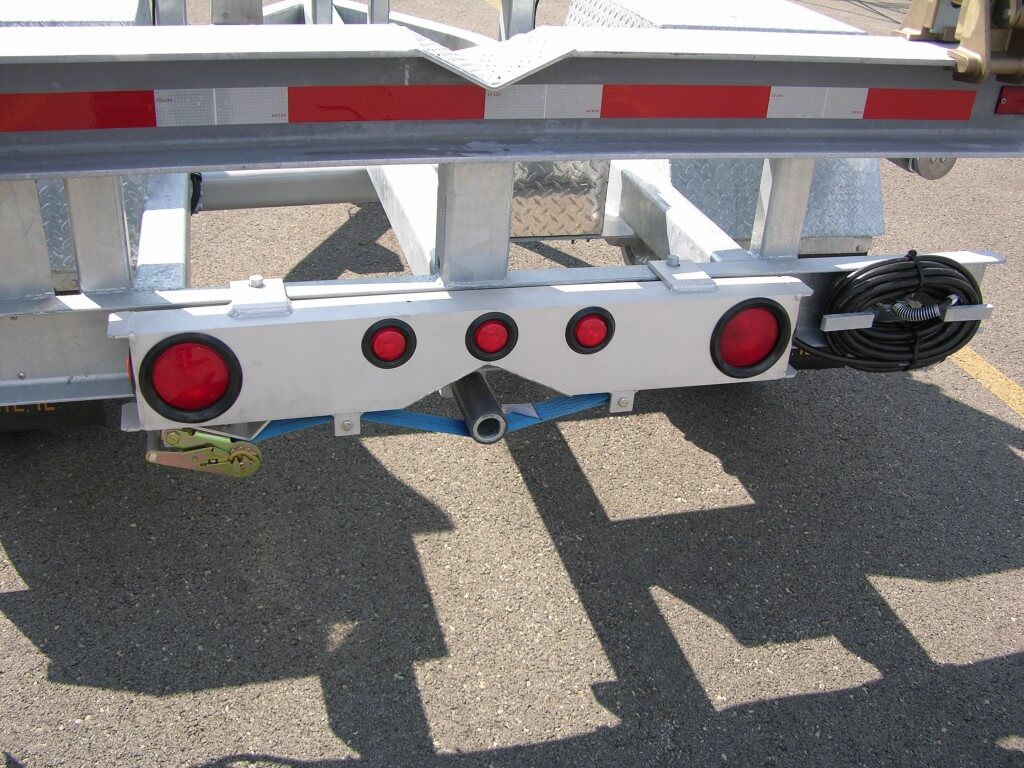

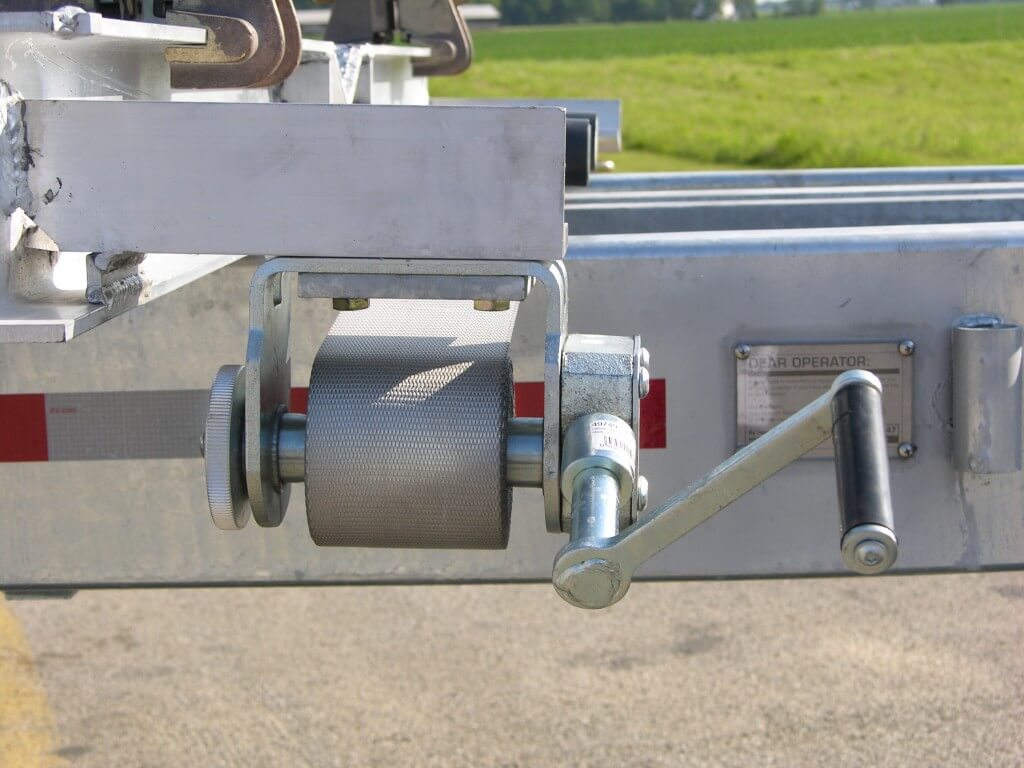

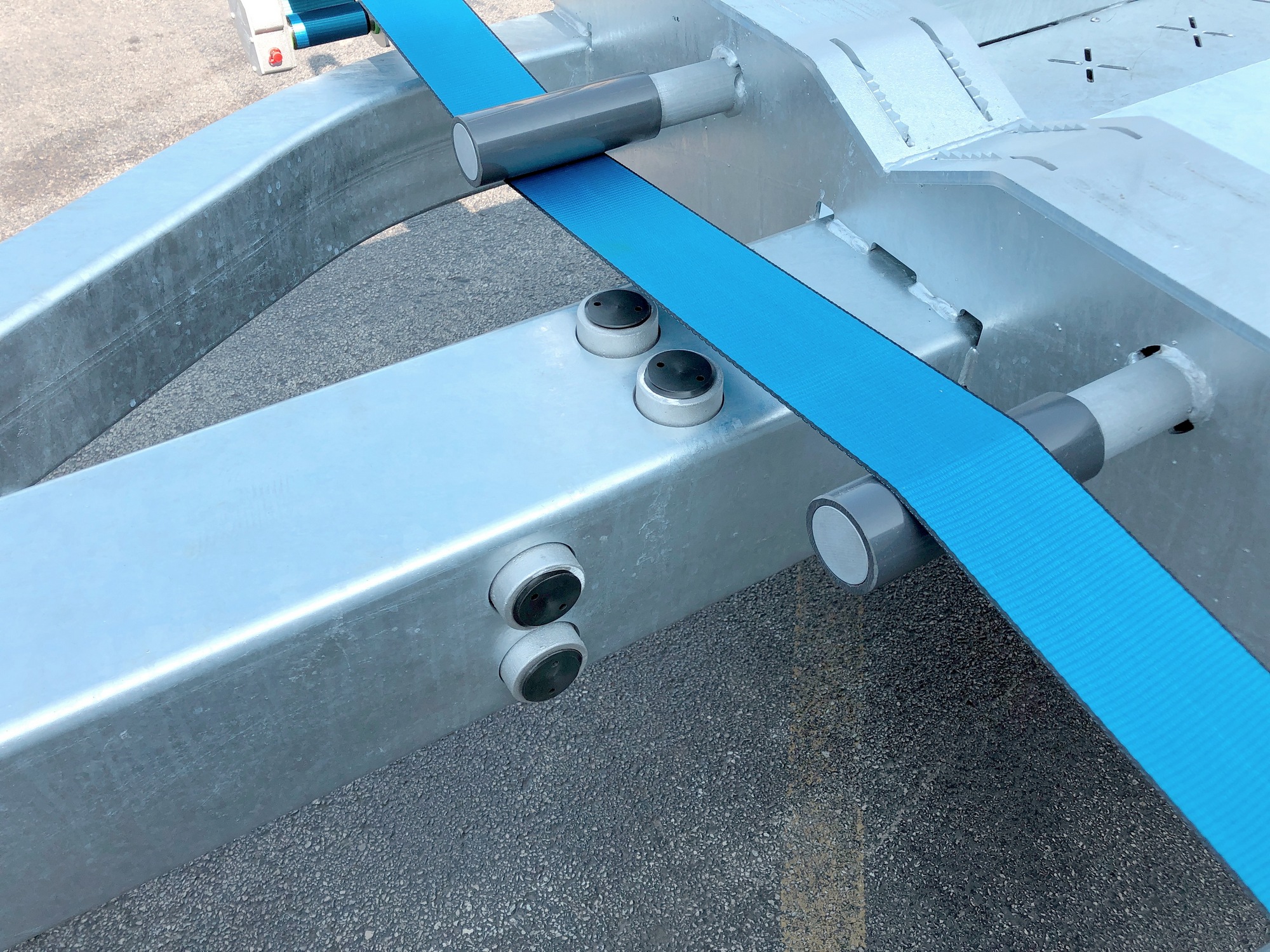

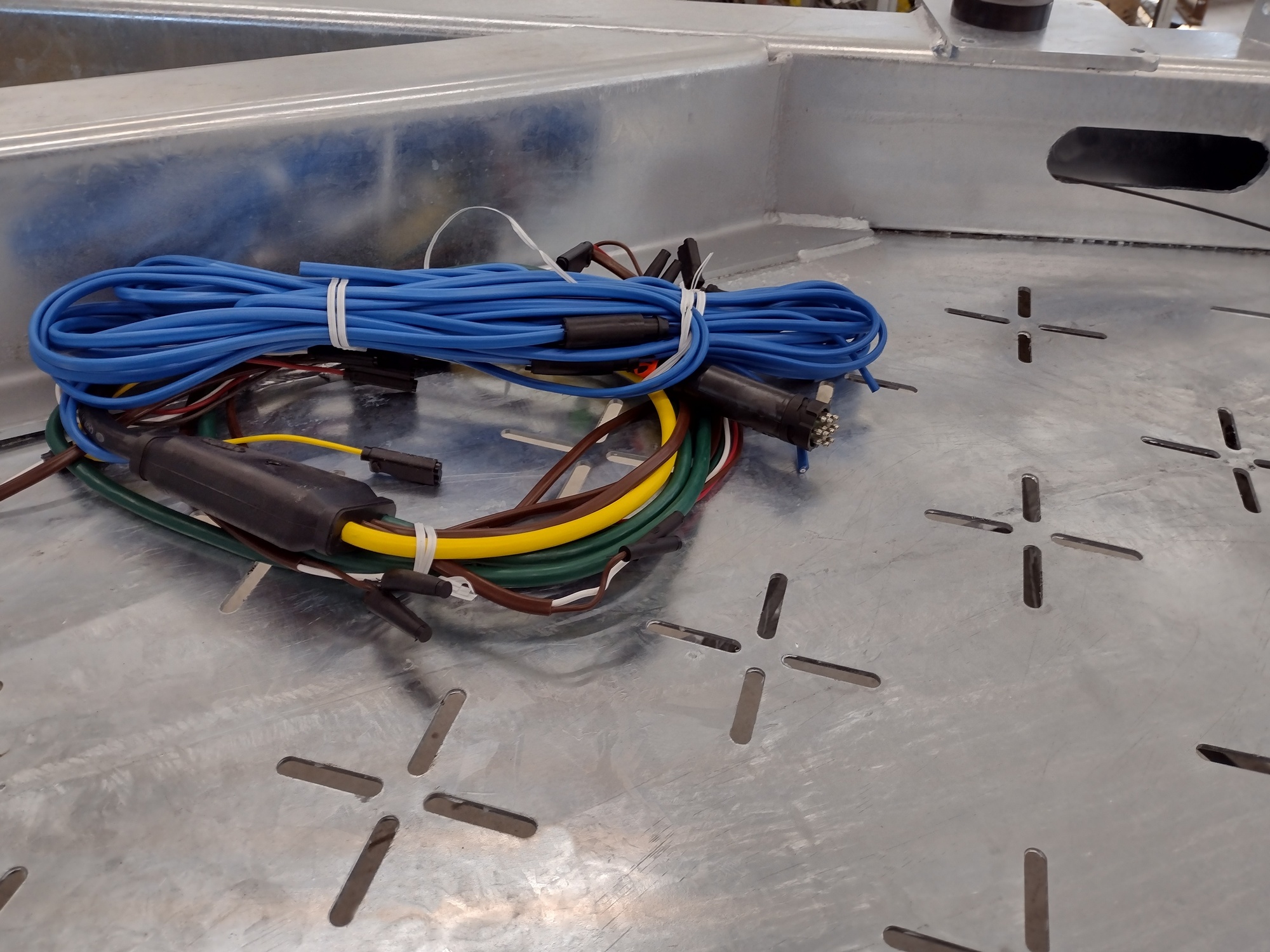

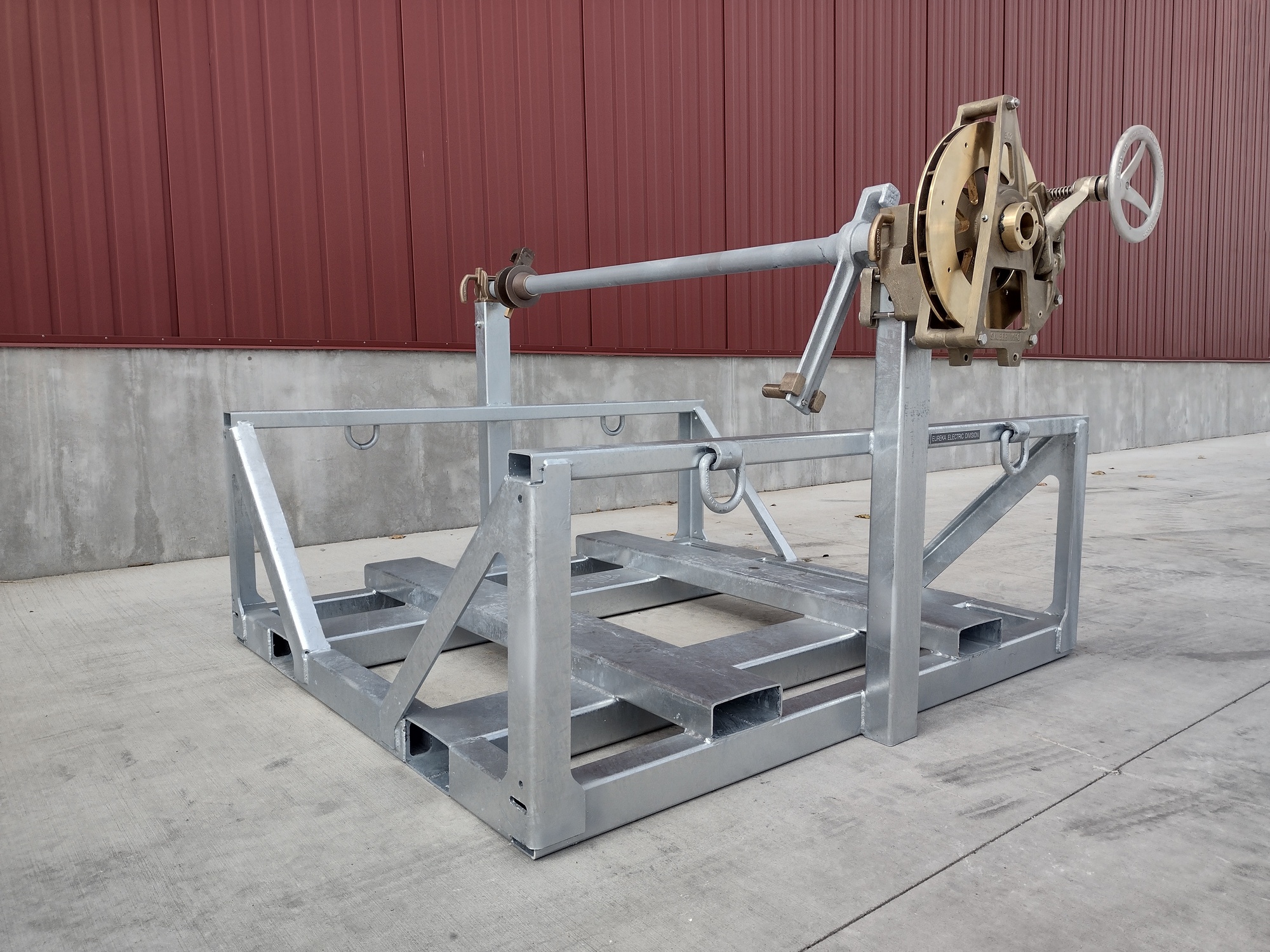

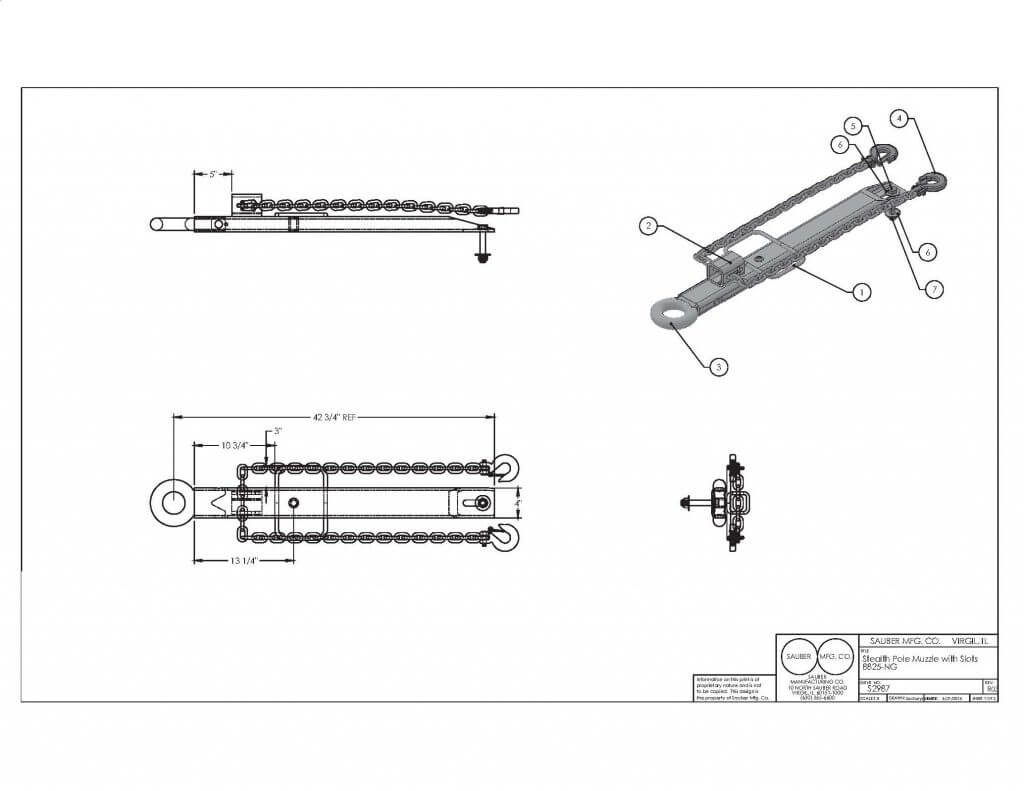

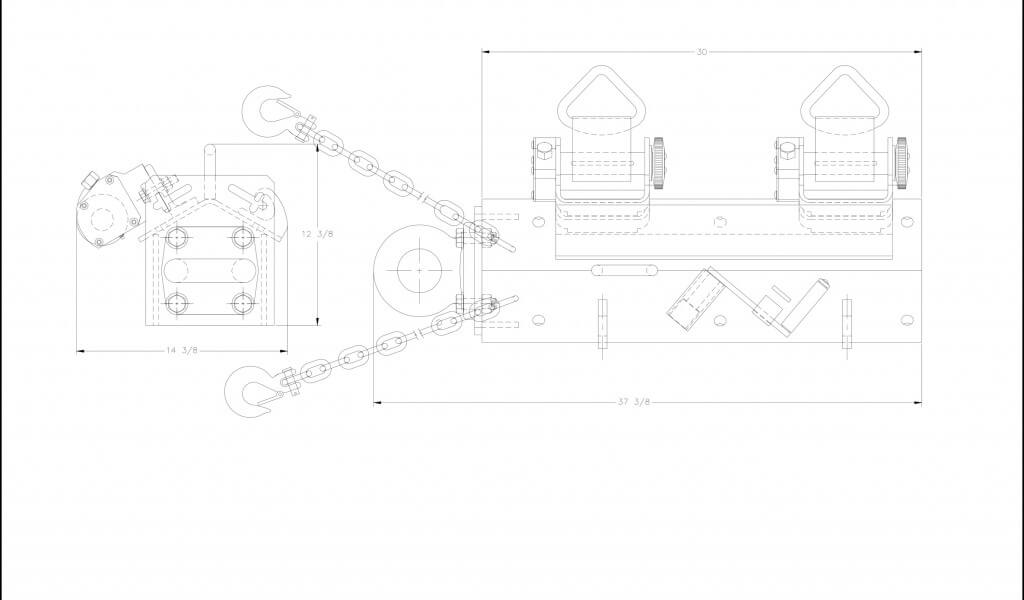

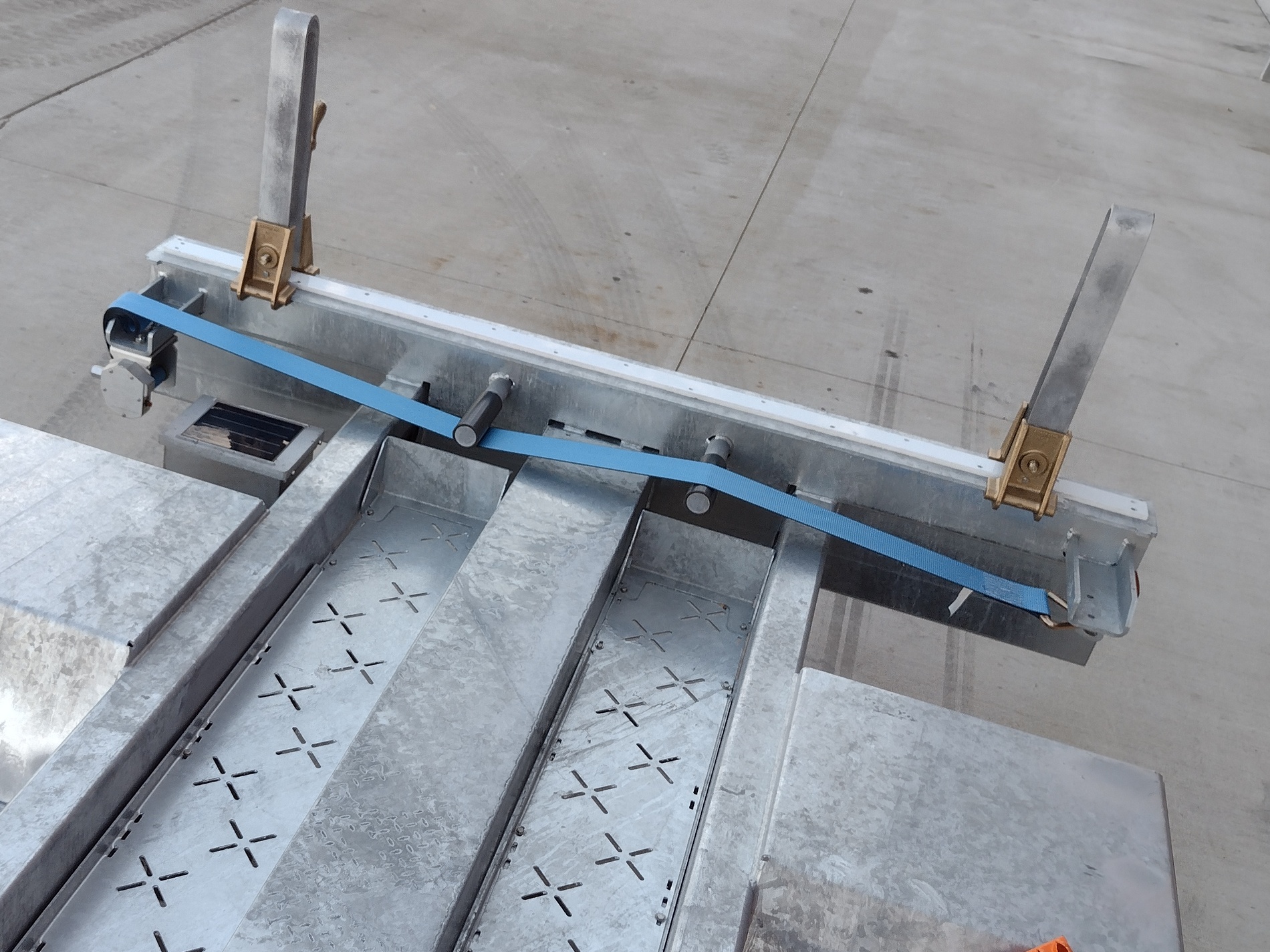

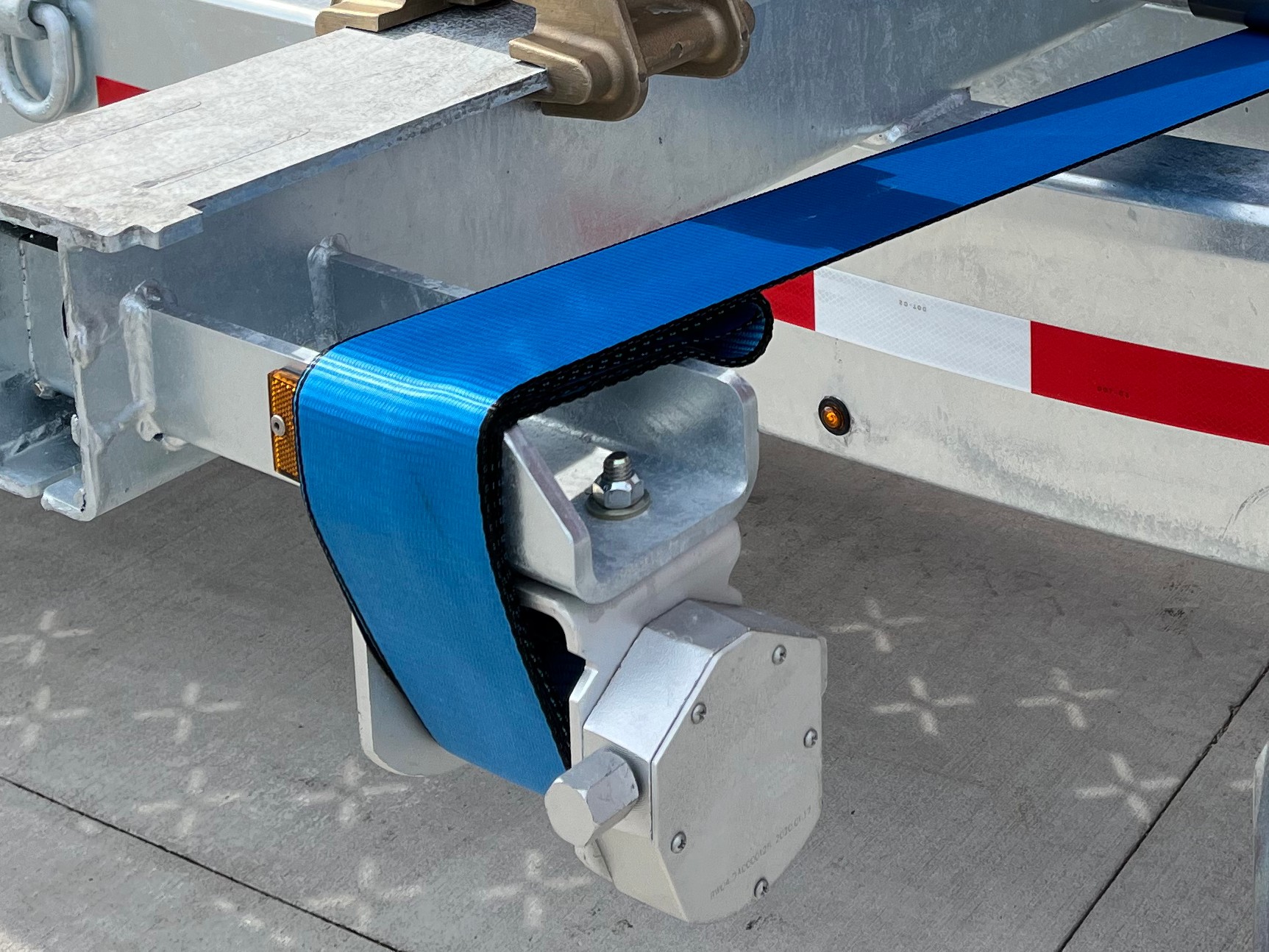

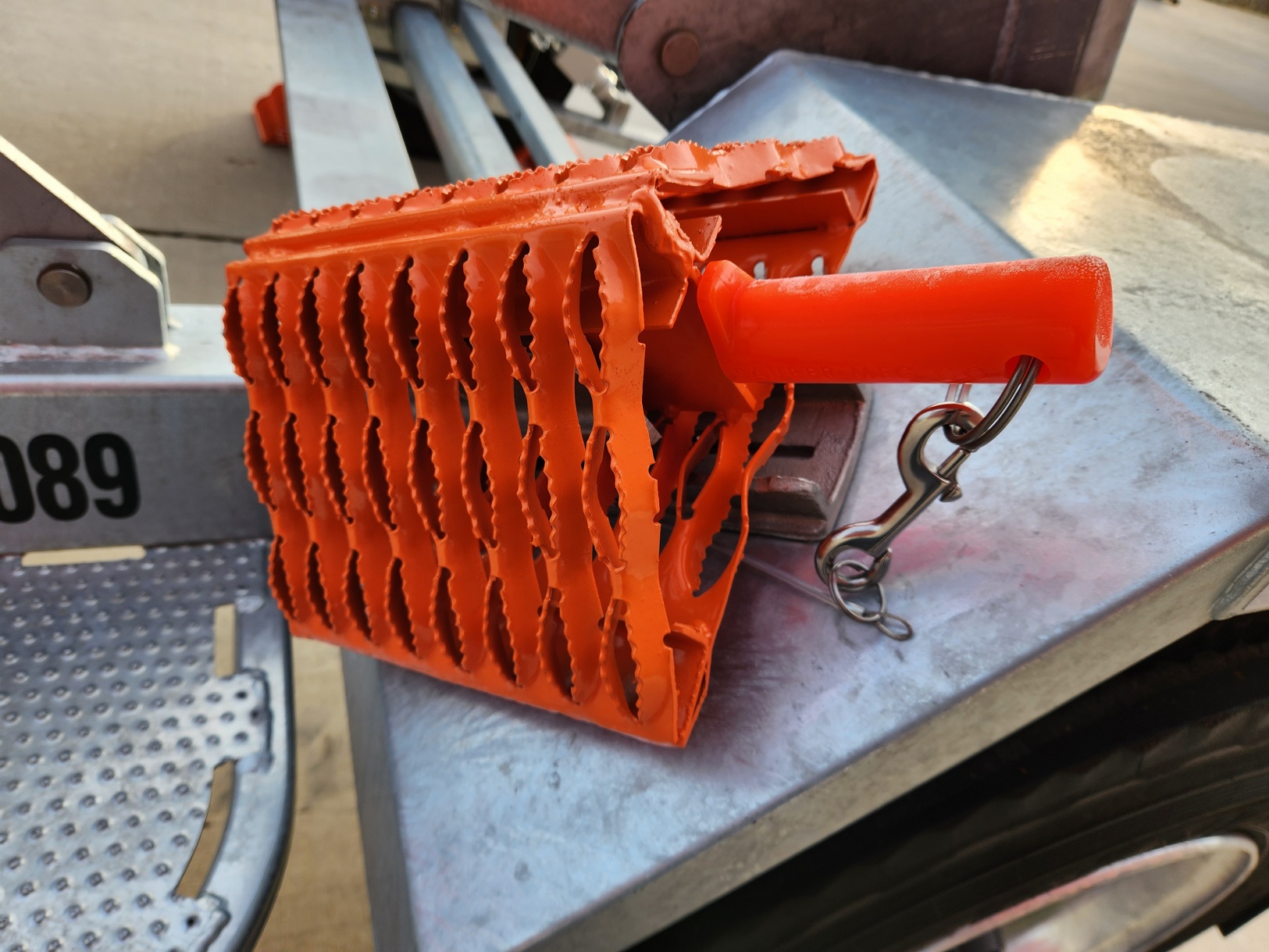

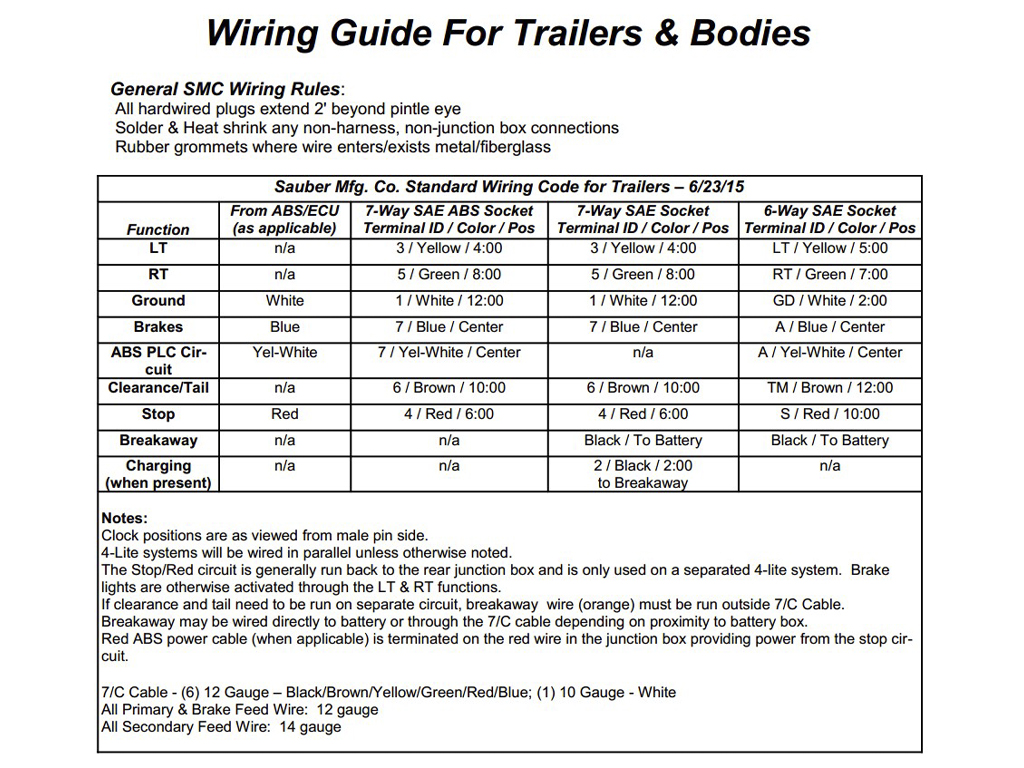

This high-capacity pole trailer fits applications where you need to support the load more fully during transport. It can be optimized for decorative or concrete poles with bolster liners and additional cargo securement. With both front and rear extension, you’ll have a short trailer for your return trip. Like all our pole trailers you'll enjoy self-locking worm gear drive winch binders, high strength fabricated bolsters and adjustable nylon slides. Of course, the protected sectionalized wiring harness, hot dipped galvanized finish, and other Sauber Mfg. Co. standard features are included as well.

Click here to view similar Sauber Mfg. Co. Trailers.

Capacity: 26450#

GVWR: 35250#

Retracted: 35"L x 96"W

Extended: 58'L x 96"W

Benefits