Dumping Cargo Trailer

Model 1599-DT

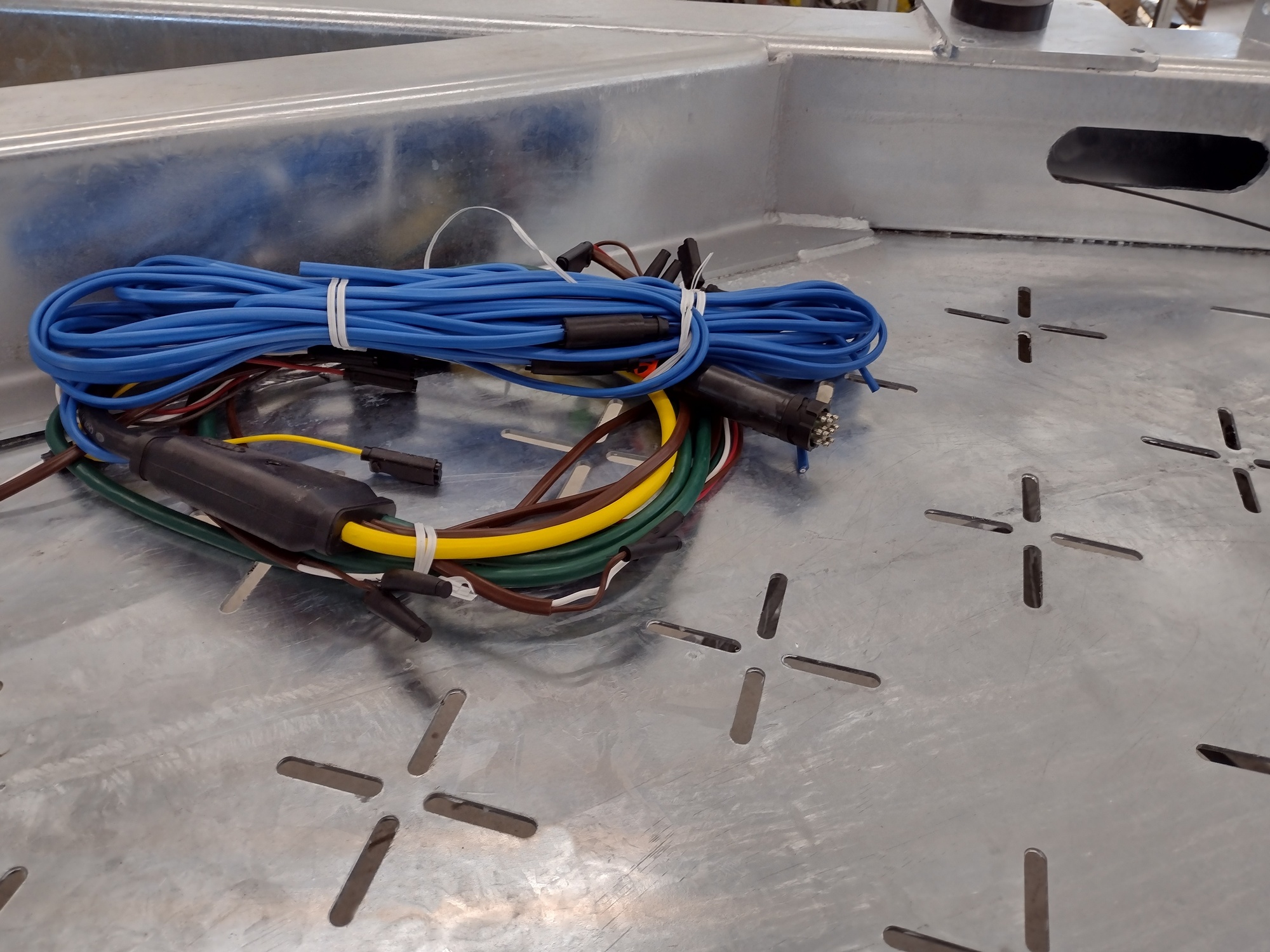

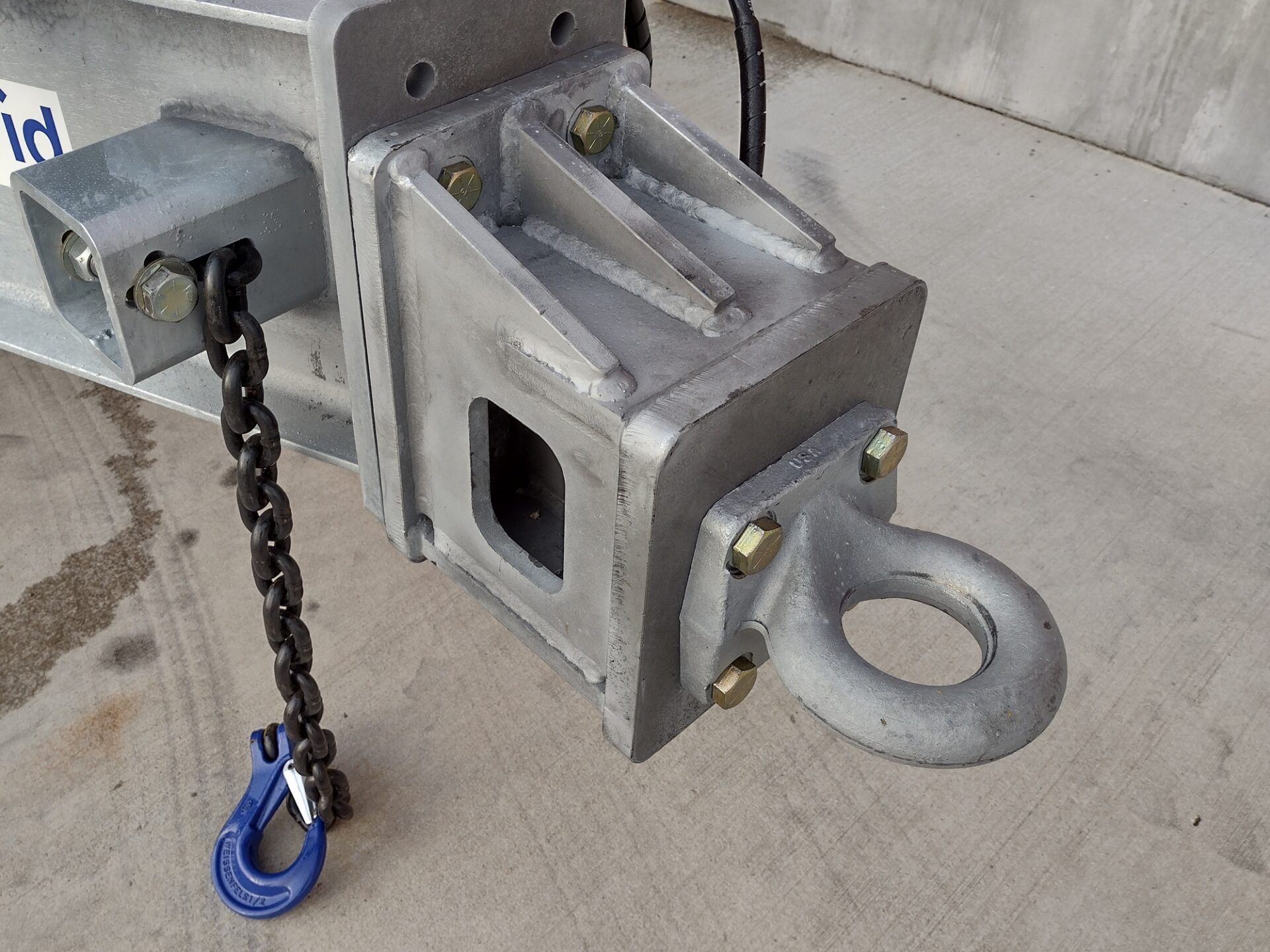

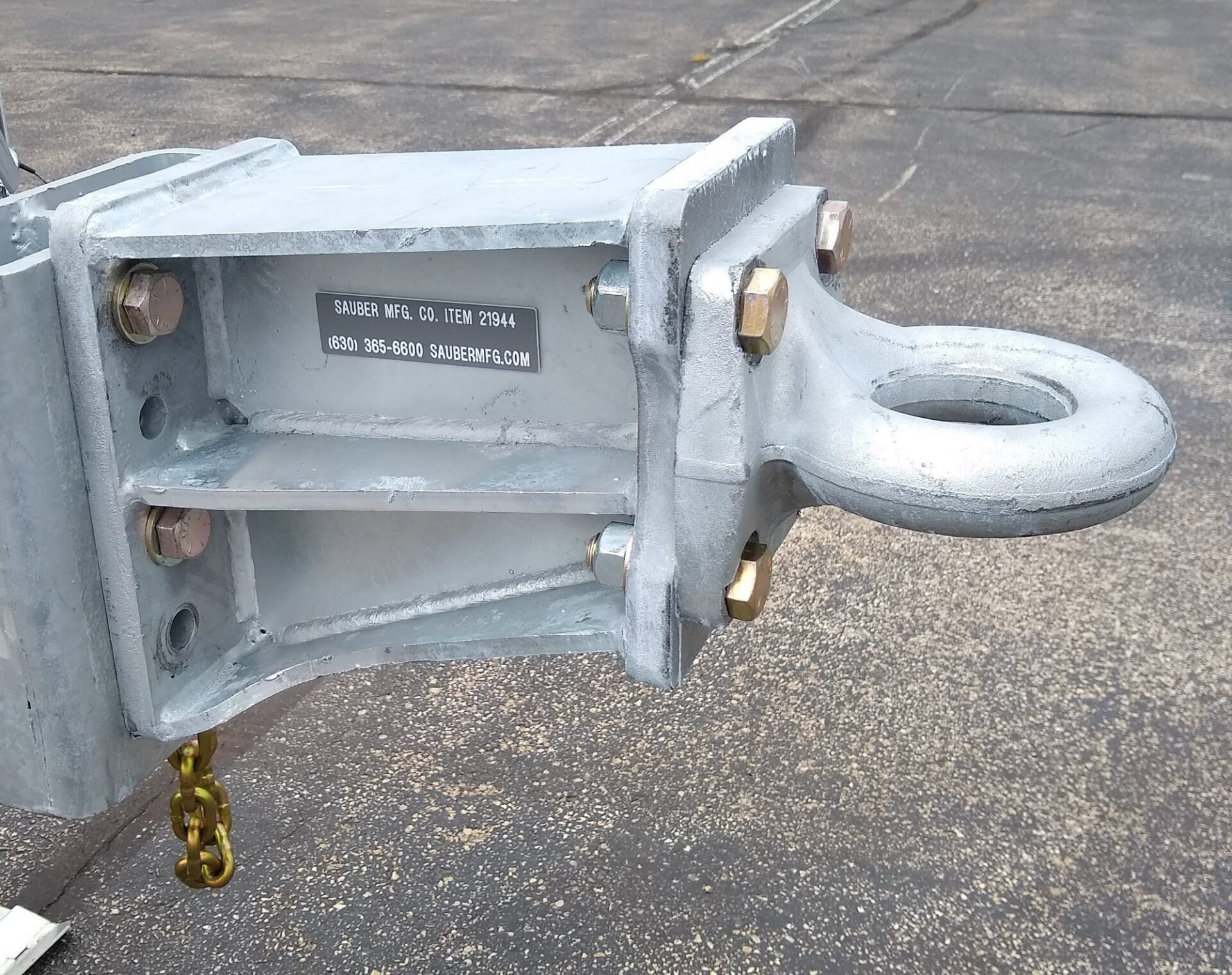

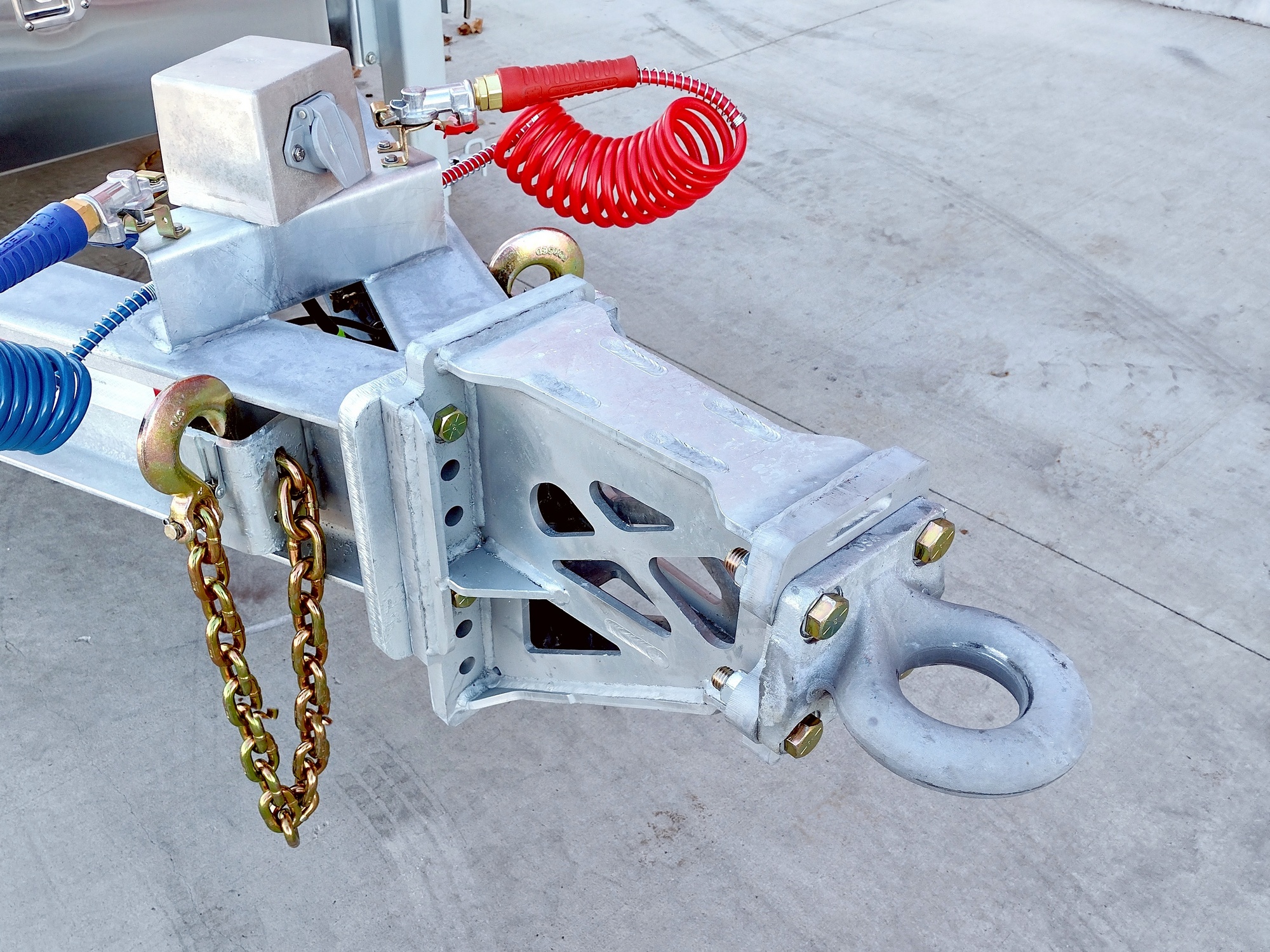

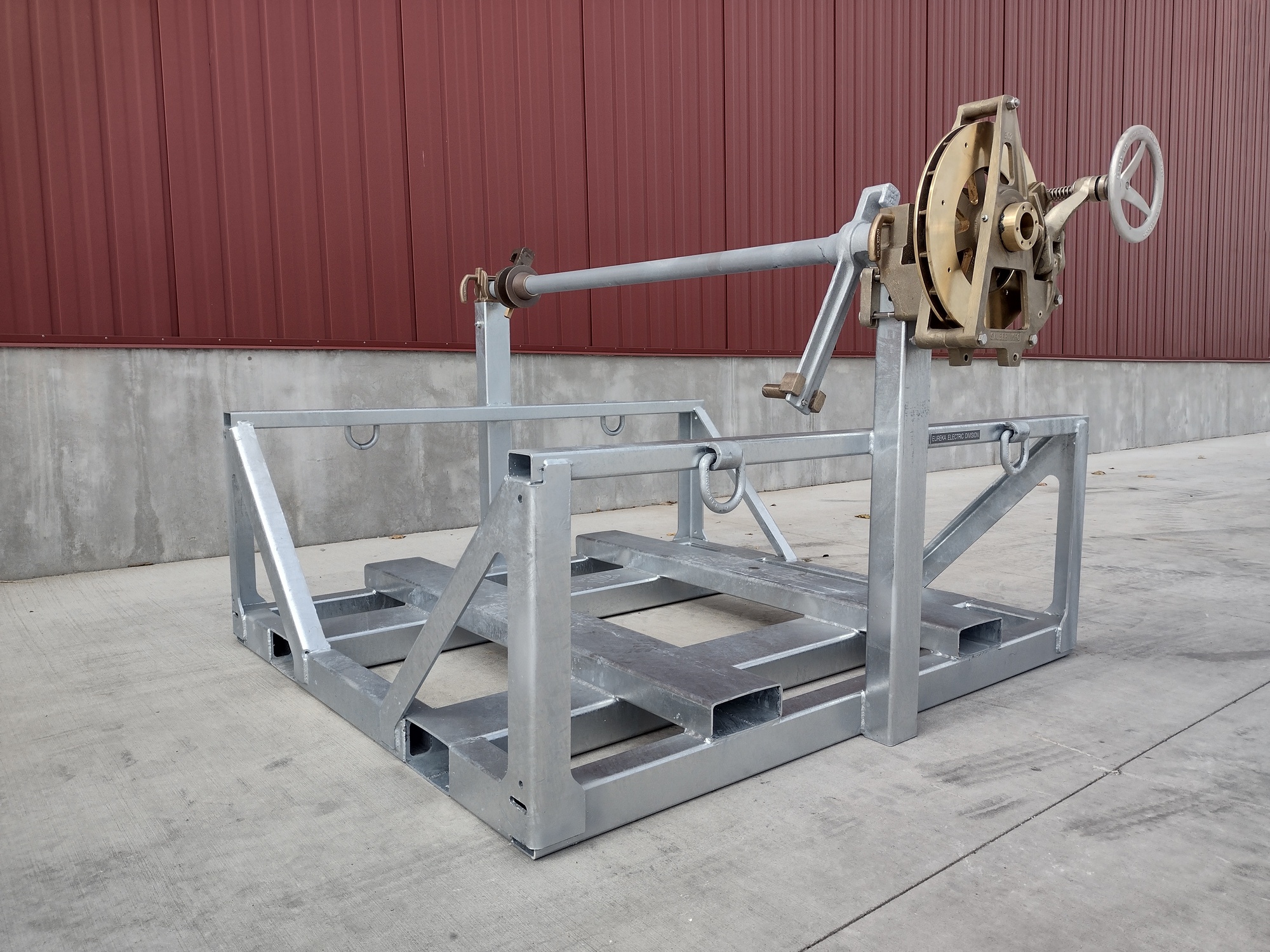

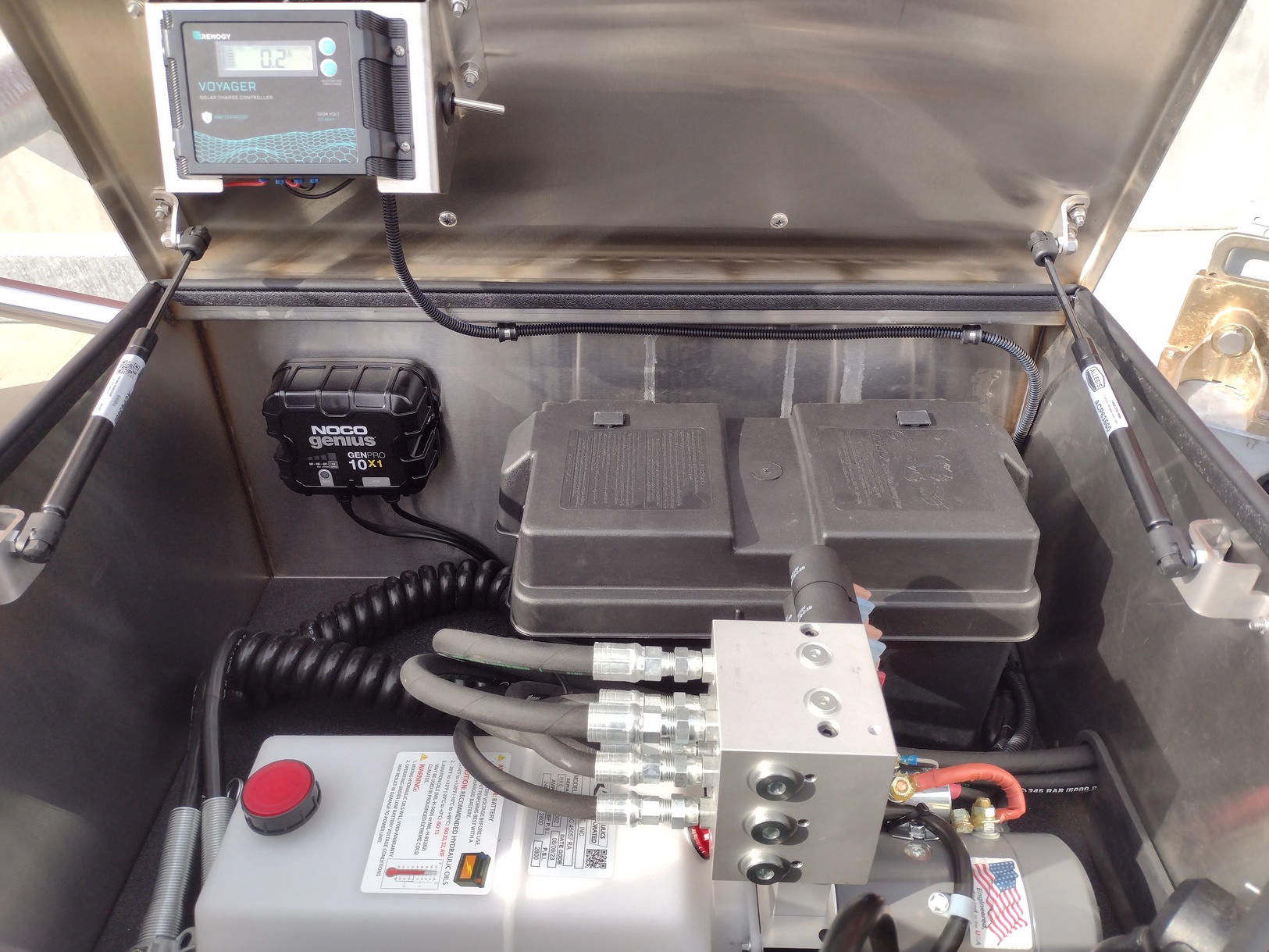

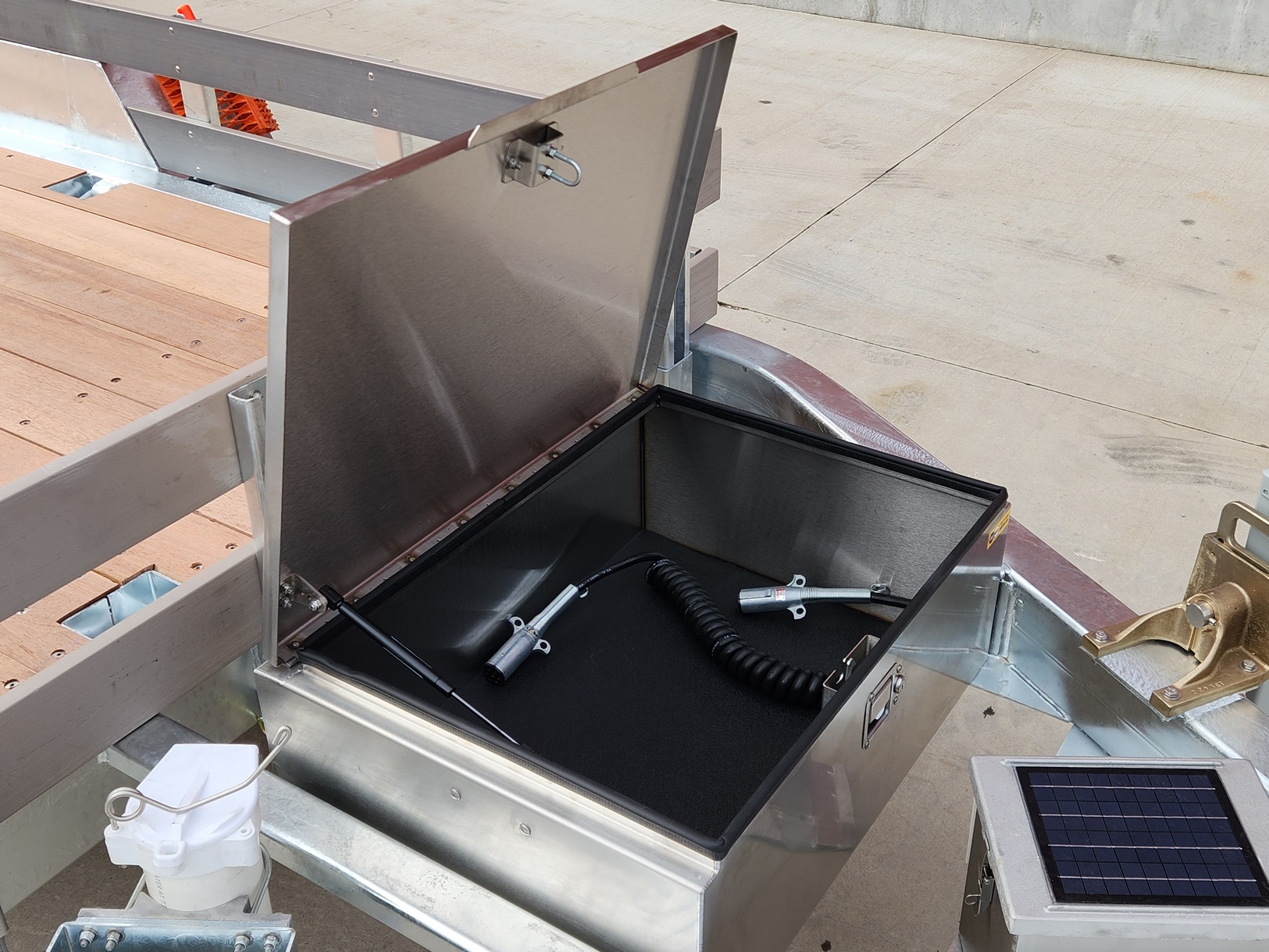

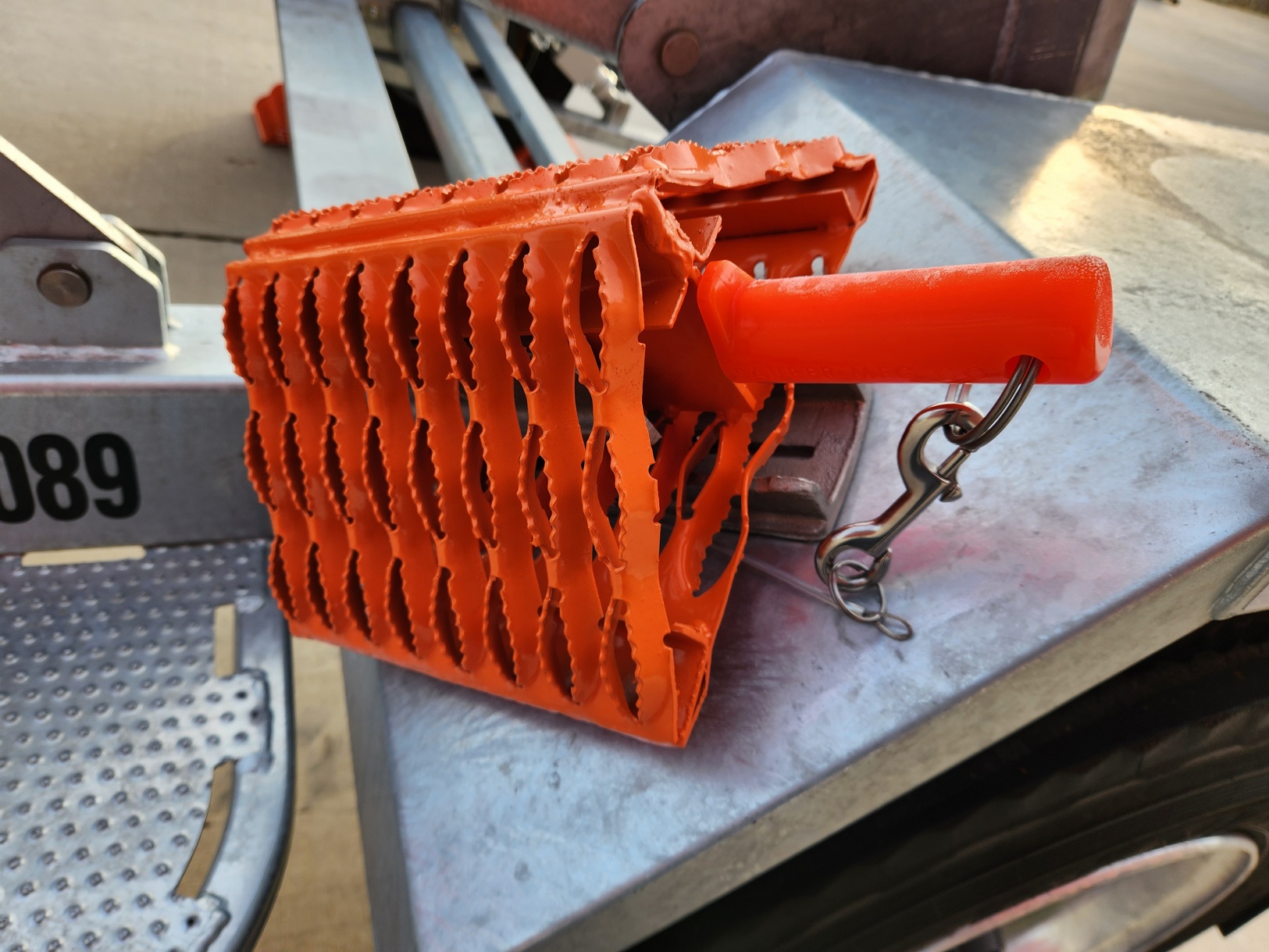

When the job calls for a reliable large dumping cargo trailer, Sauber Mfg. Co. has your solution. Rely on standard features like bent tube frames, stainless steel pivot pins with oil lite bushings and hot dipped galvanized finish to for a low maintenance, and long life. With the Sauber SmartPower 12VDC Electric/Hydraulic Power Source this unit has the reliable power you need. Increase the utility of this dumping cargo trailer with optional features like ramps, tarp systems and reel carriers. Contact us today.

Click here to see similar equipment.

Capacity: 11240#

GVWR: 16450#

Dimensions: 20'L x 96"W; 144"x 72"Cargo