Wire Service Trailer

Model 1599-WS

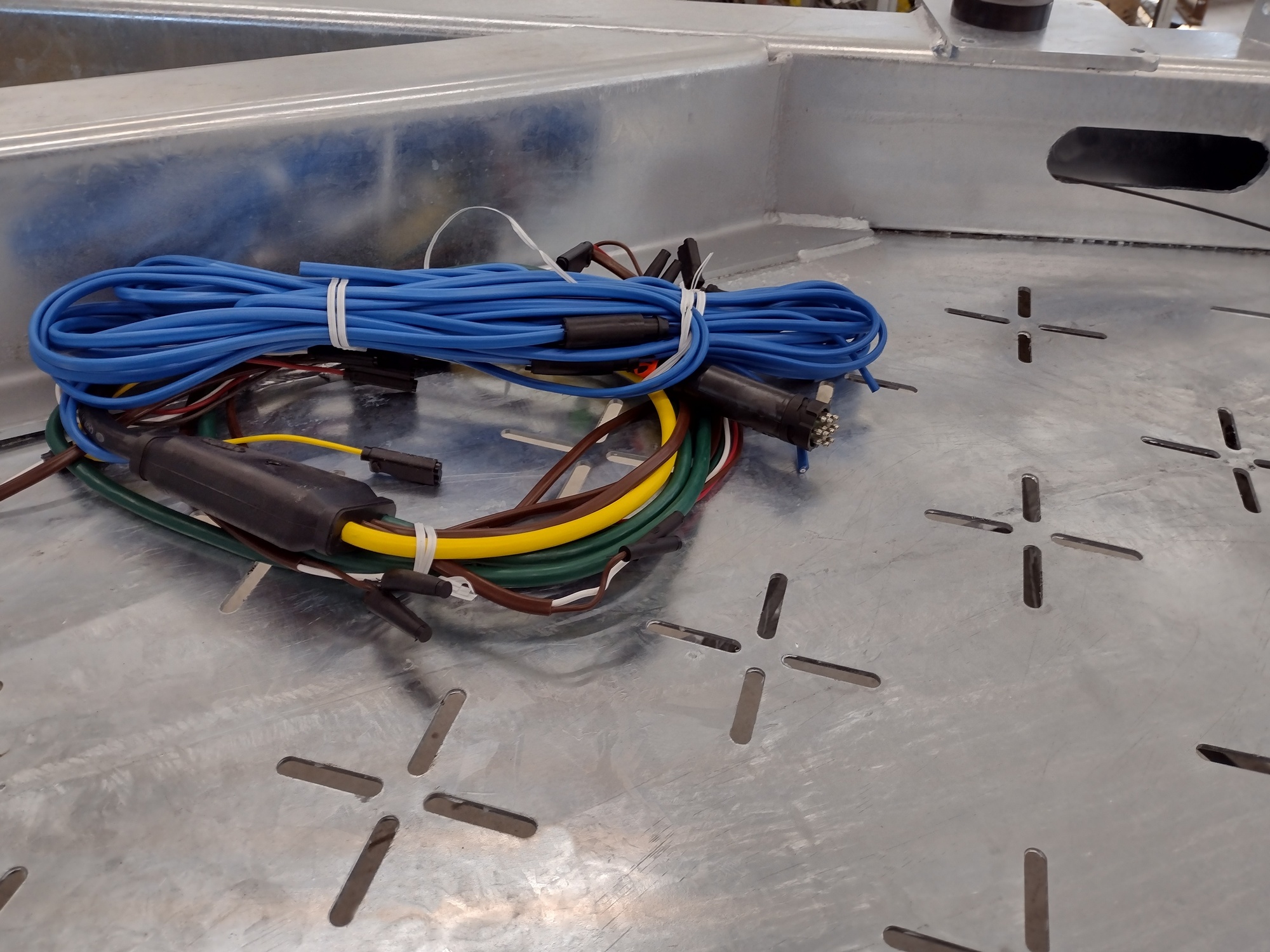

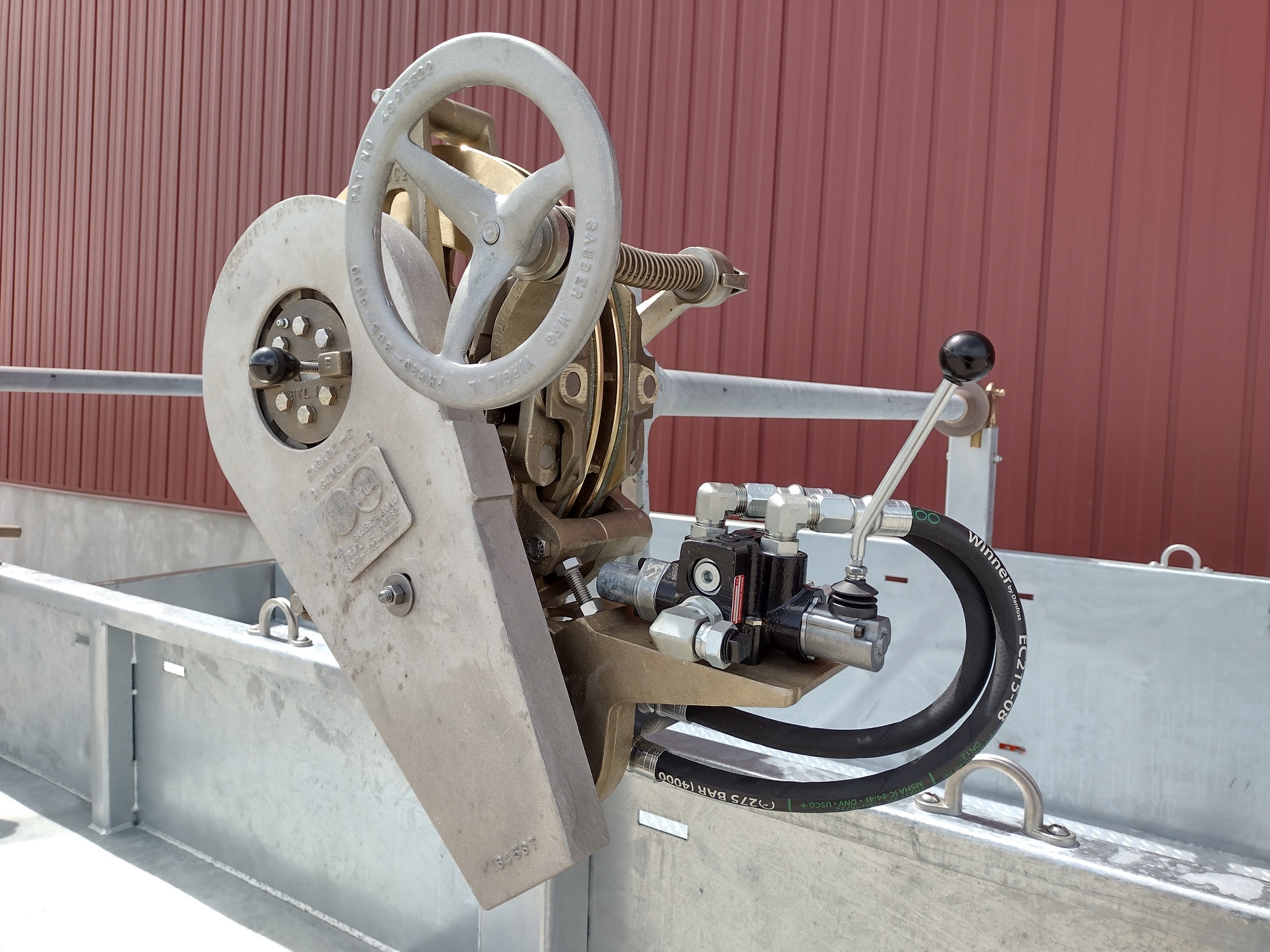

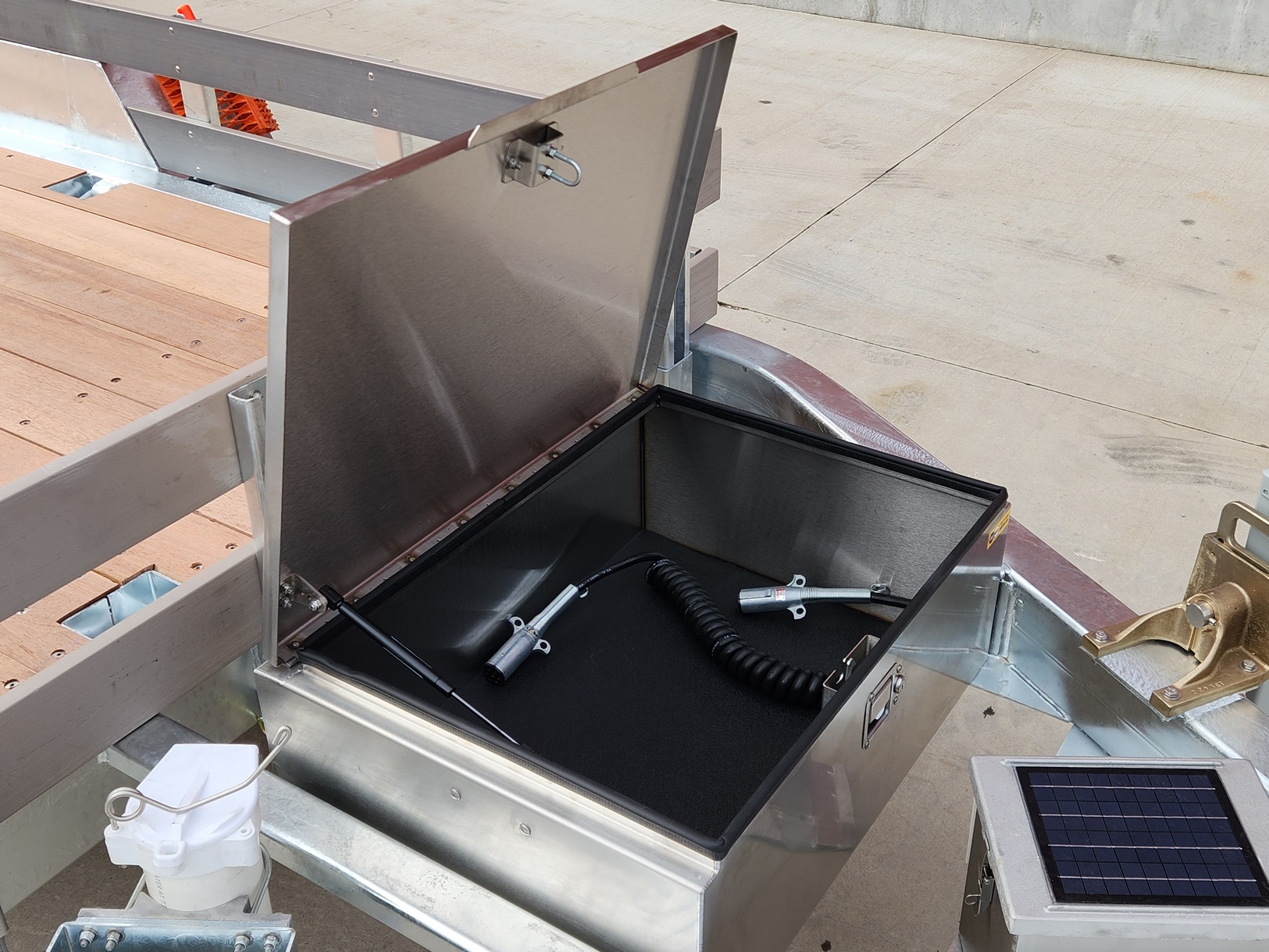

Configured specifically for underground fault response, our Model 1599-WS Wire Service Trailer puts you in control of the outage situation. Your crews gain storage for the tools, components and wire required to connect power around the underground fault. Once the power is on, you gain the time needed to plan efficient repair of the underground lines. Our commitment to durability ensures the wire service trailer will be ready to work at a moment’s notice.

Click here for other specialty equipment.

Capacity: 5950#

GVWR: 8750#

Reel Size: 54" OD x 36" ID, 6" & 27" Compartments

Dimensions: 18'L x 96"W