Pole Trailer

Model 4500

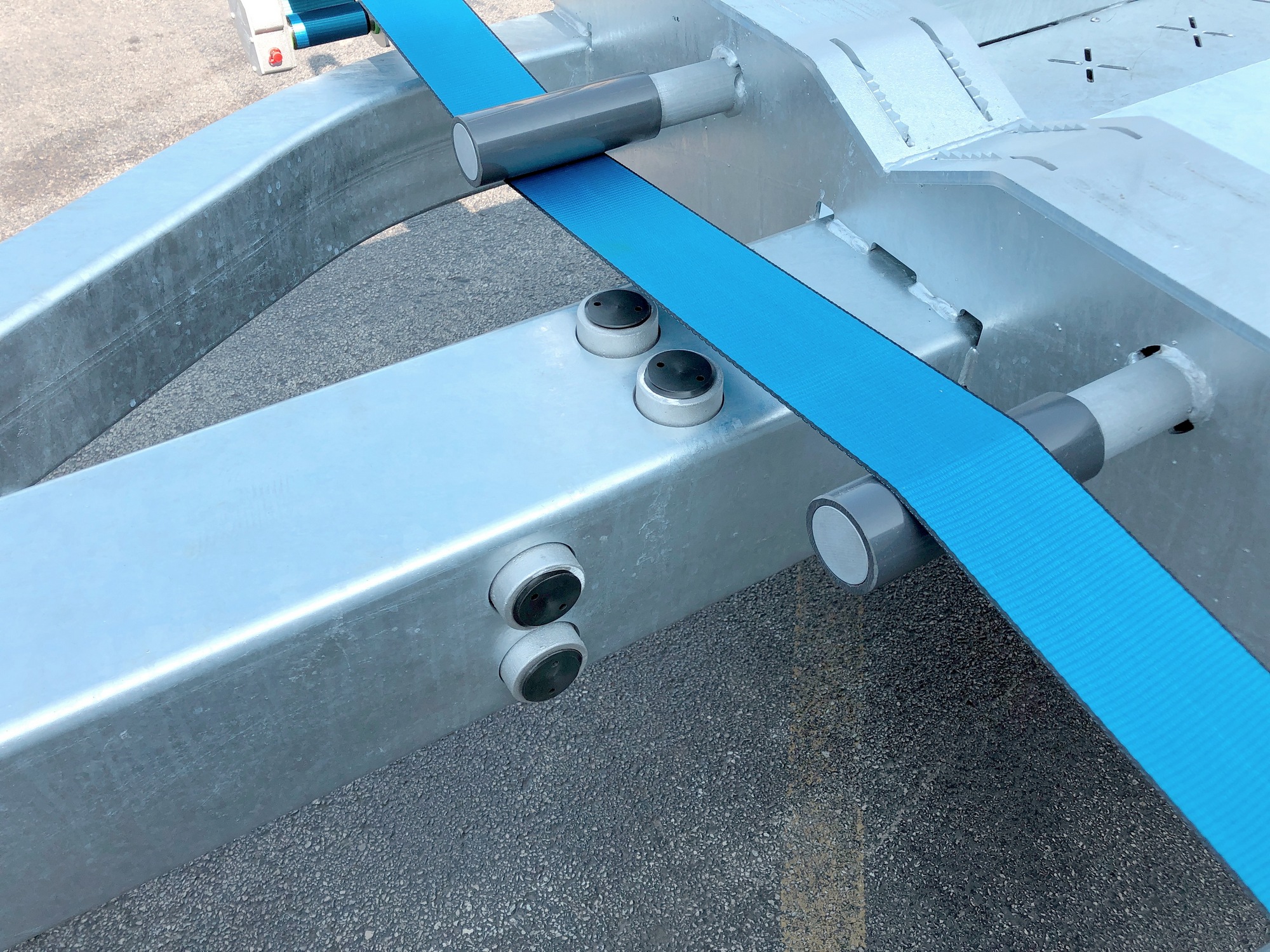

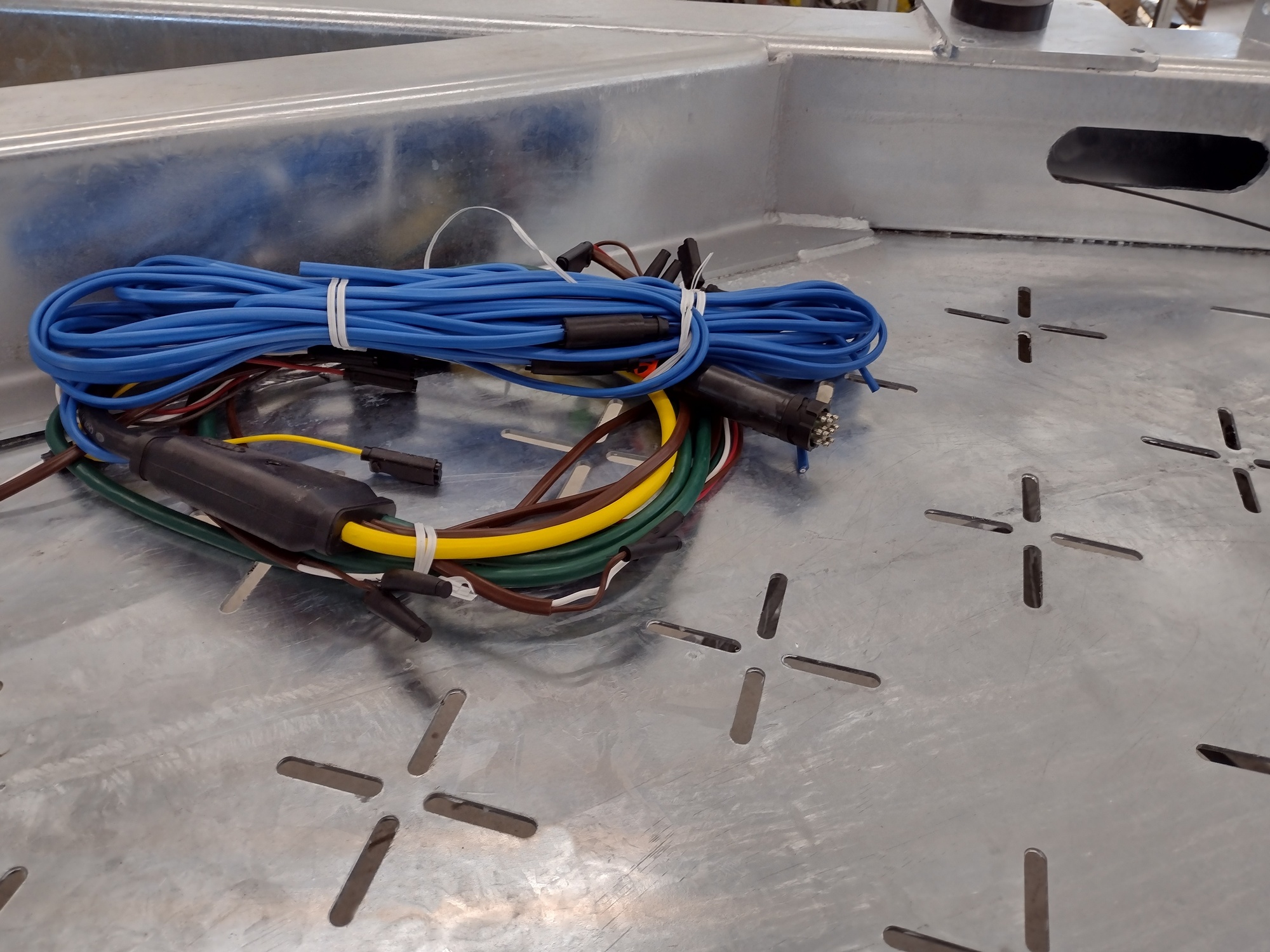

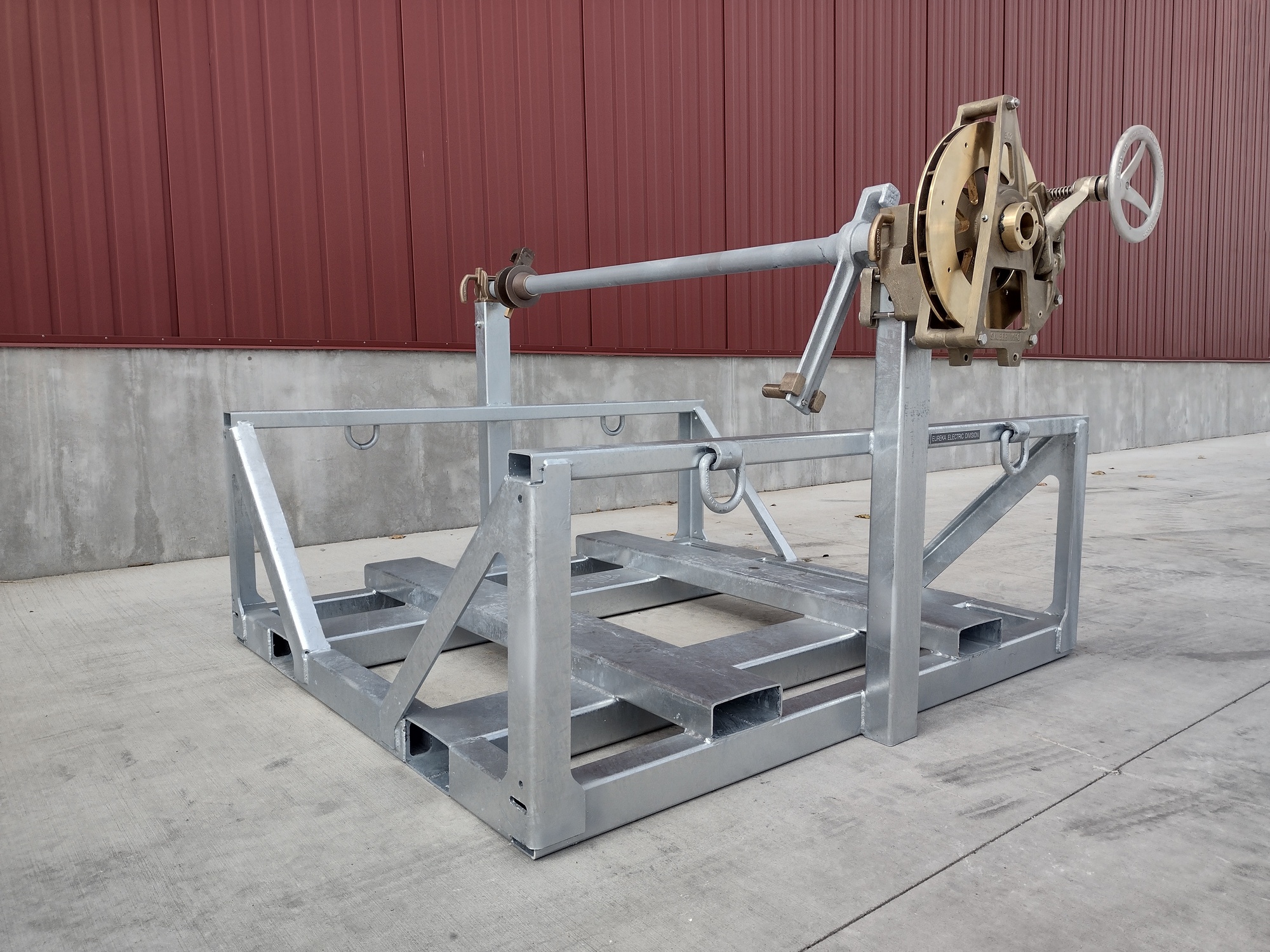

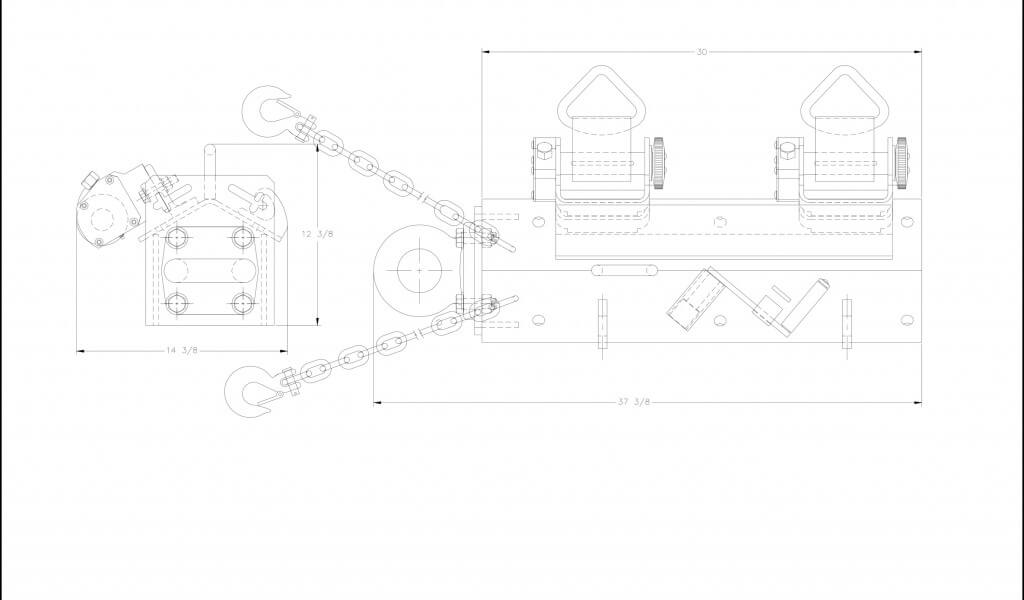

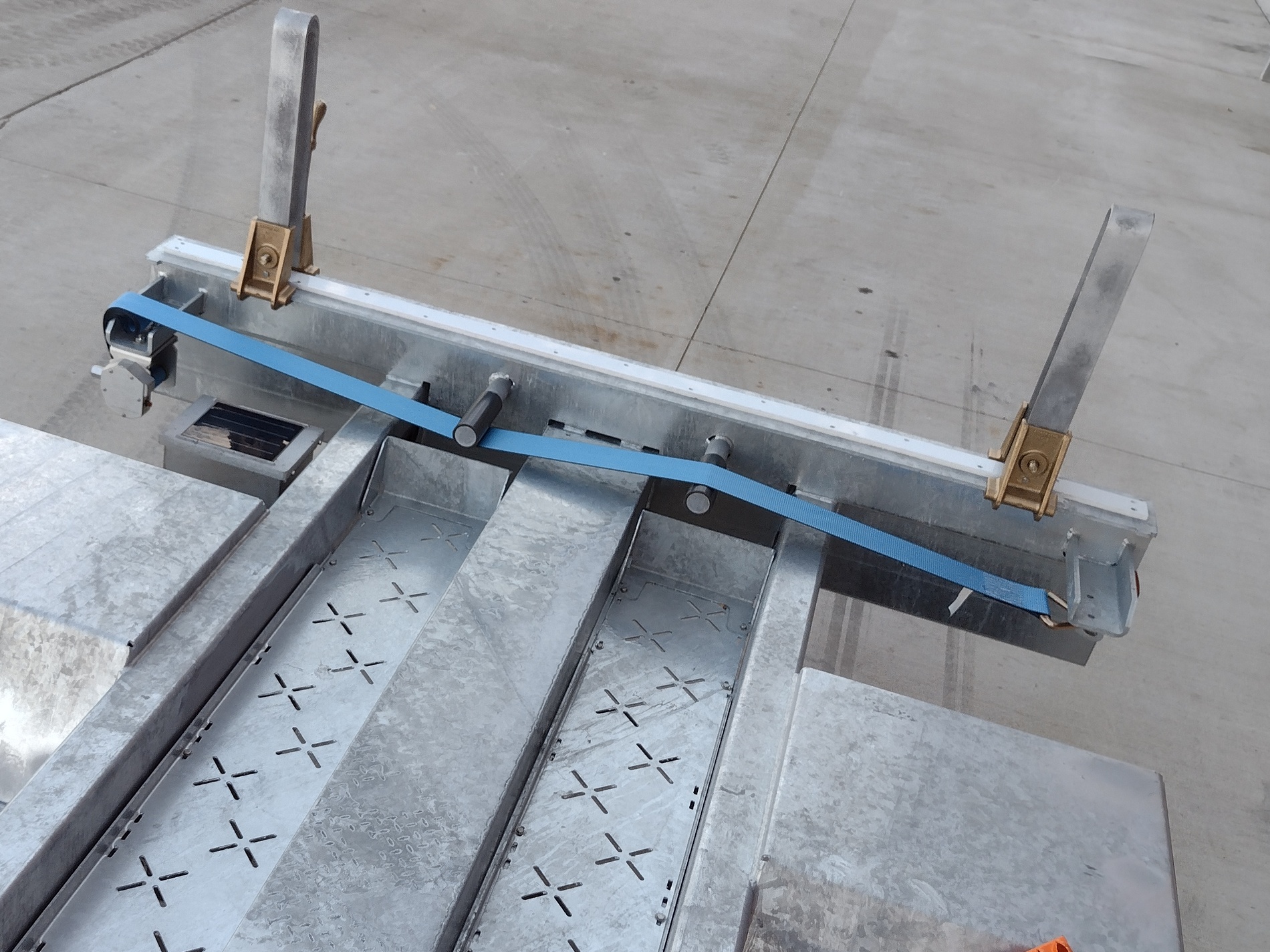

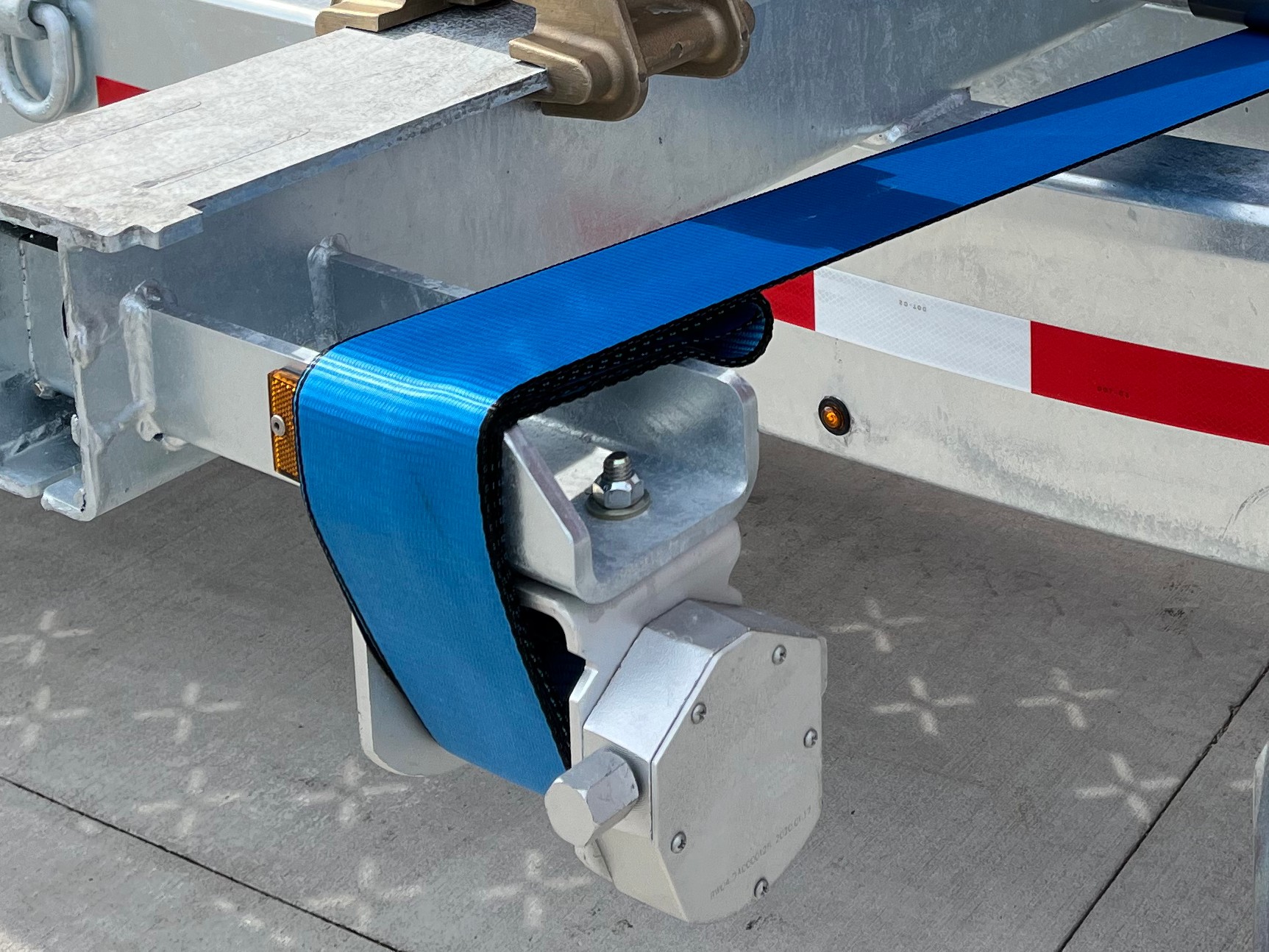

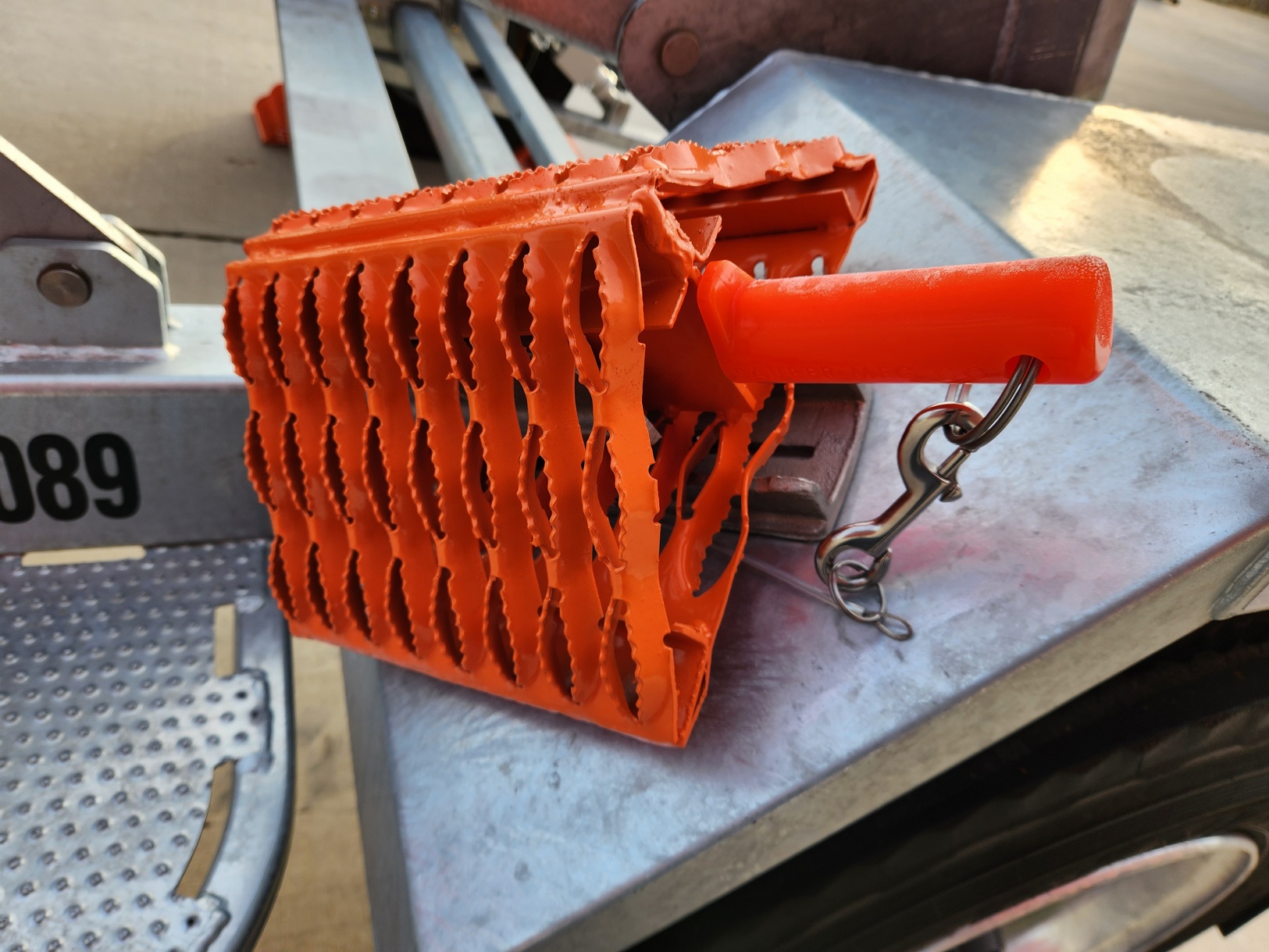

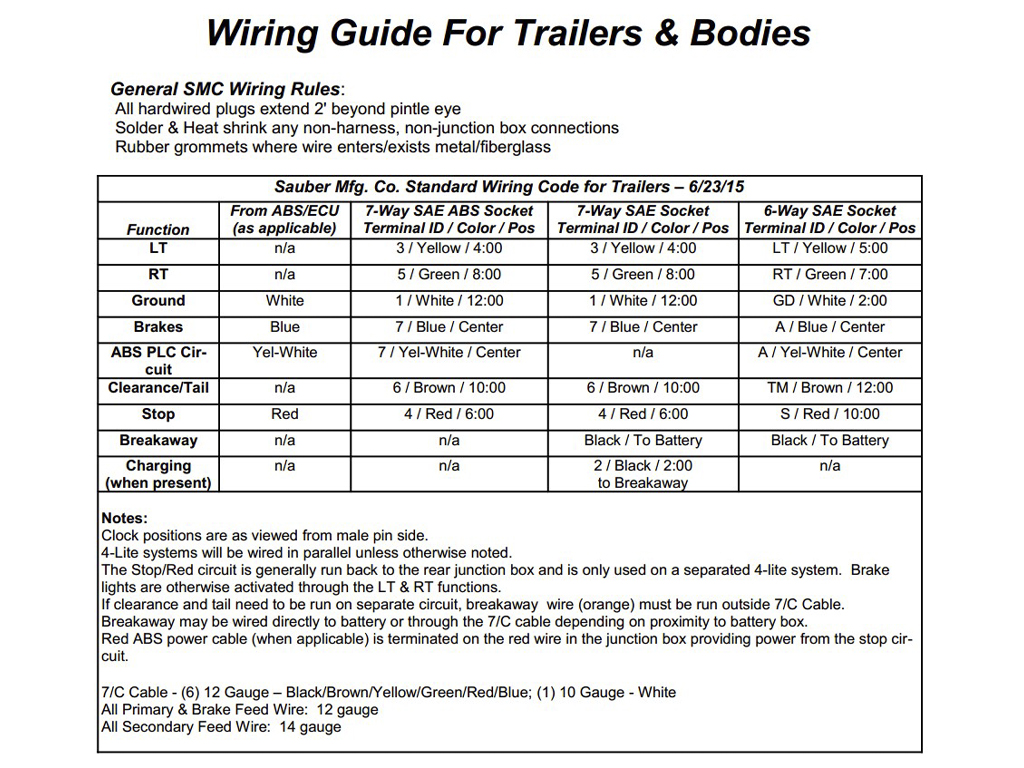

Pole hauling is demanding work and your crews need great performance, easy use and durability. The advanced design features of this large extendible pole trailer include a durable nylon slide system, non-rusting components and integral aluminum light bar to meet these requirements. From the dual 10K EZ Up Jacks to the standard self-locking worm gear drive winches, you’ll see that this trailer makes the work easier and safer. Configurable for large pole lengths and high weight capacities, work with us to specify the Model 4500 Pole Trailer to fit your work requirements. The standard hot dipped galvanized finish, protected wiring harness with cat track tongue system and bronze stanchion insure operability throughout your trailer’s long life.

Click here to see similar equipment.

Capacity: 14730#

GVWR: 18750#

Retracted: 22'L x 90"W

Extended: 30'L x 90"W LR H

Benefits