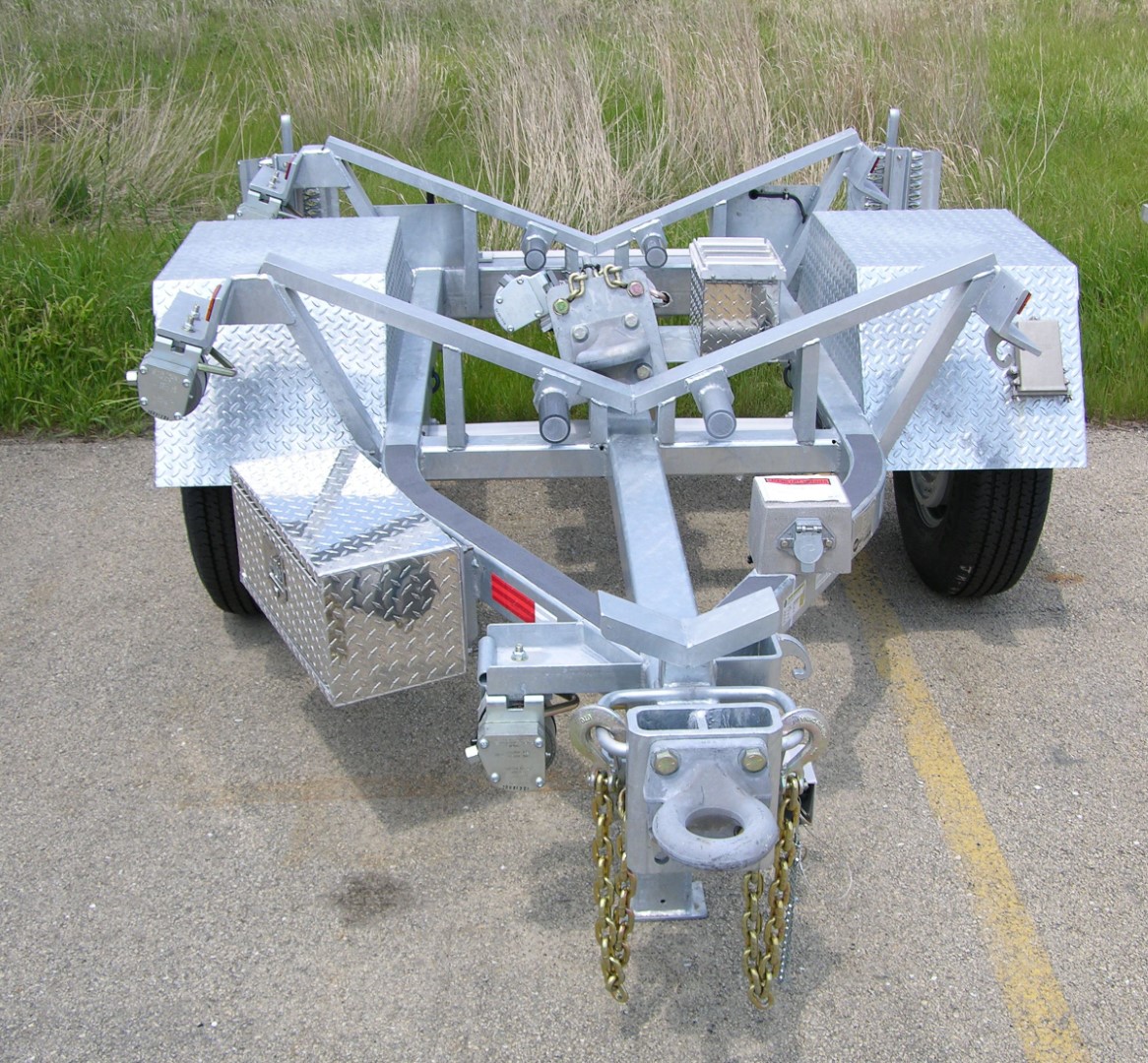

Pole Dinkey

Model 4501

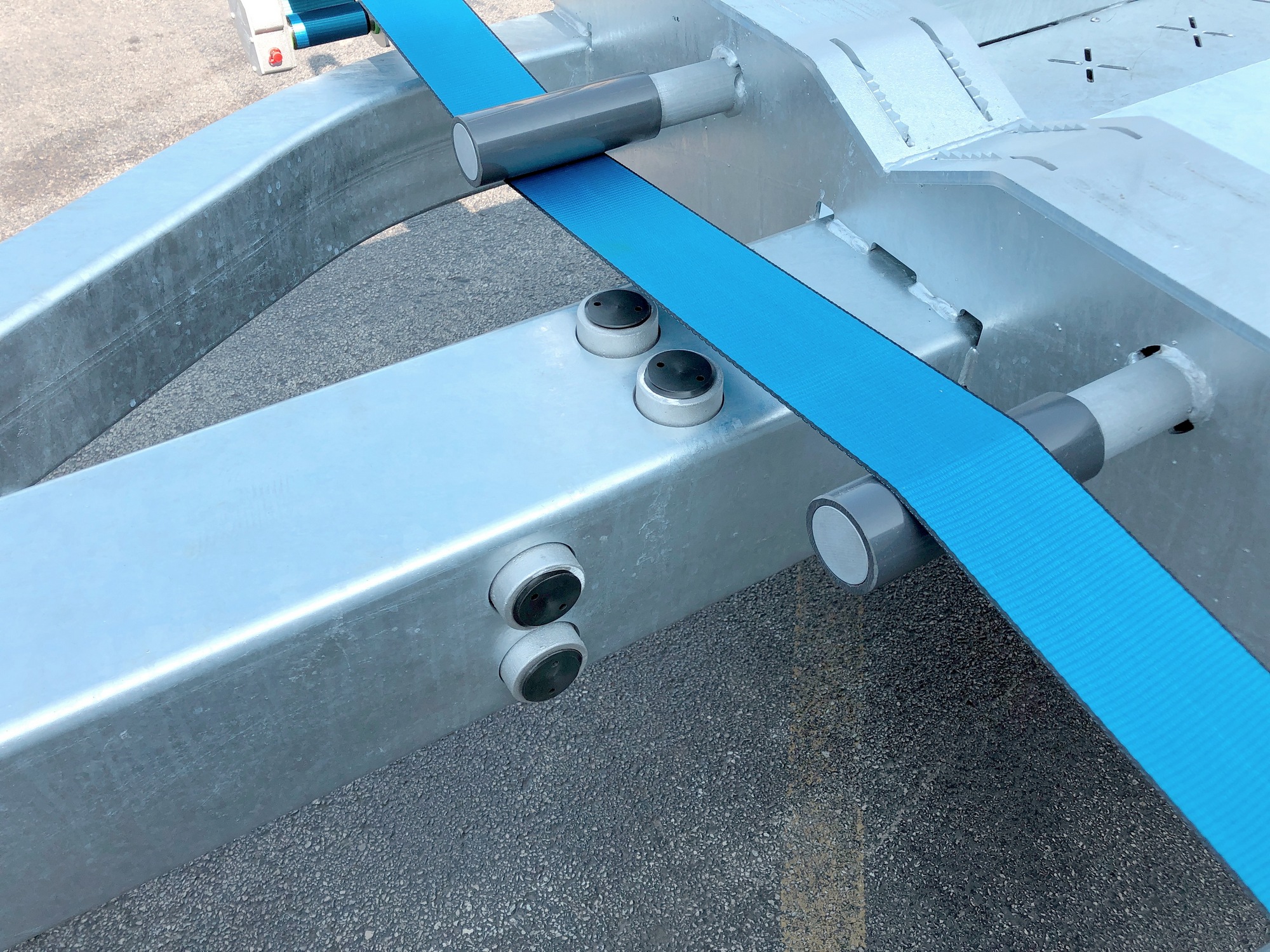

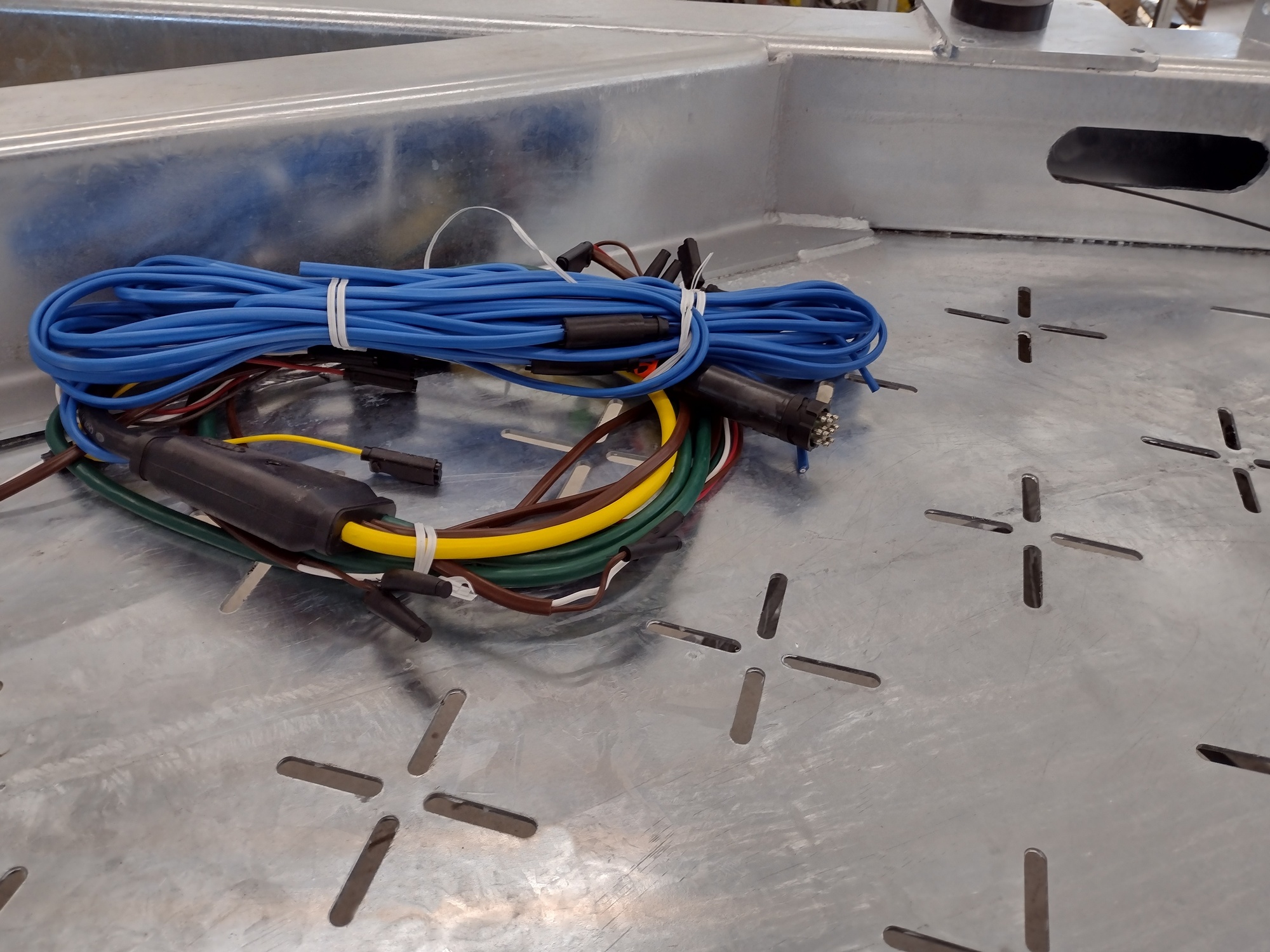

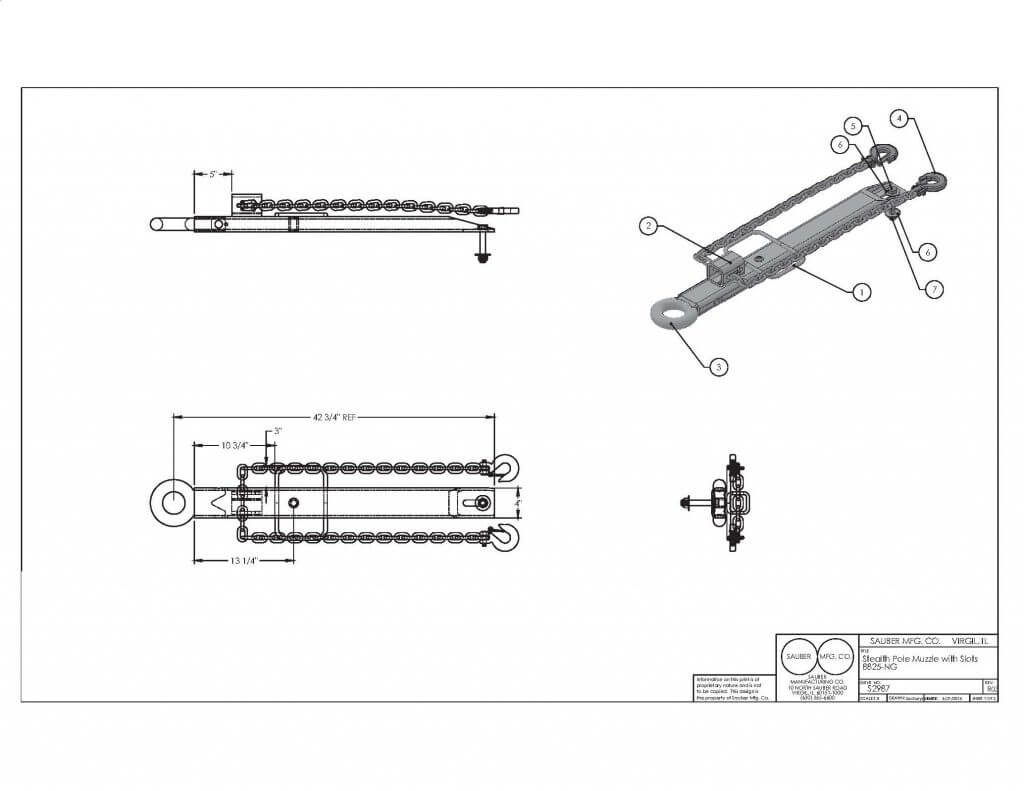

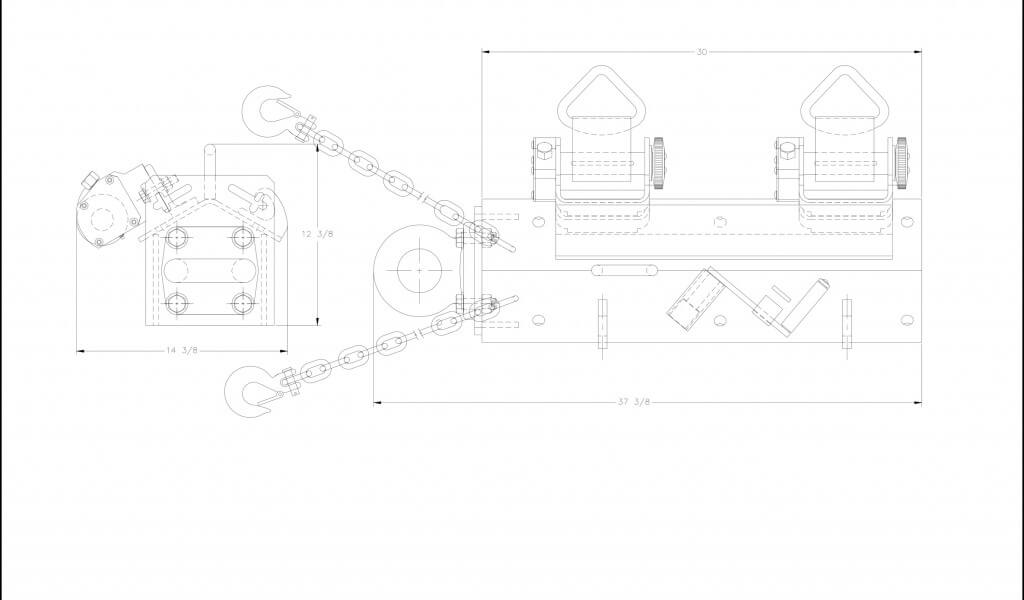

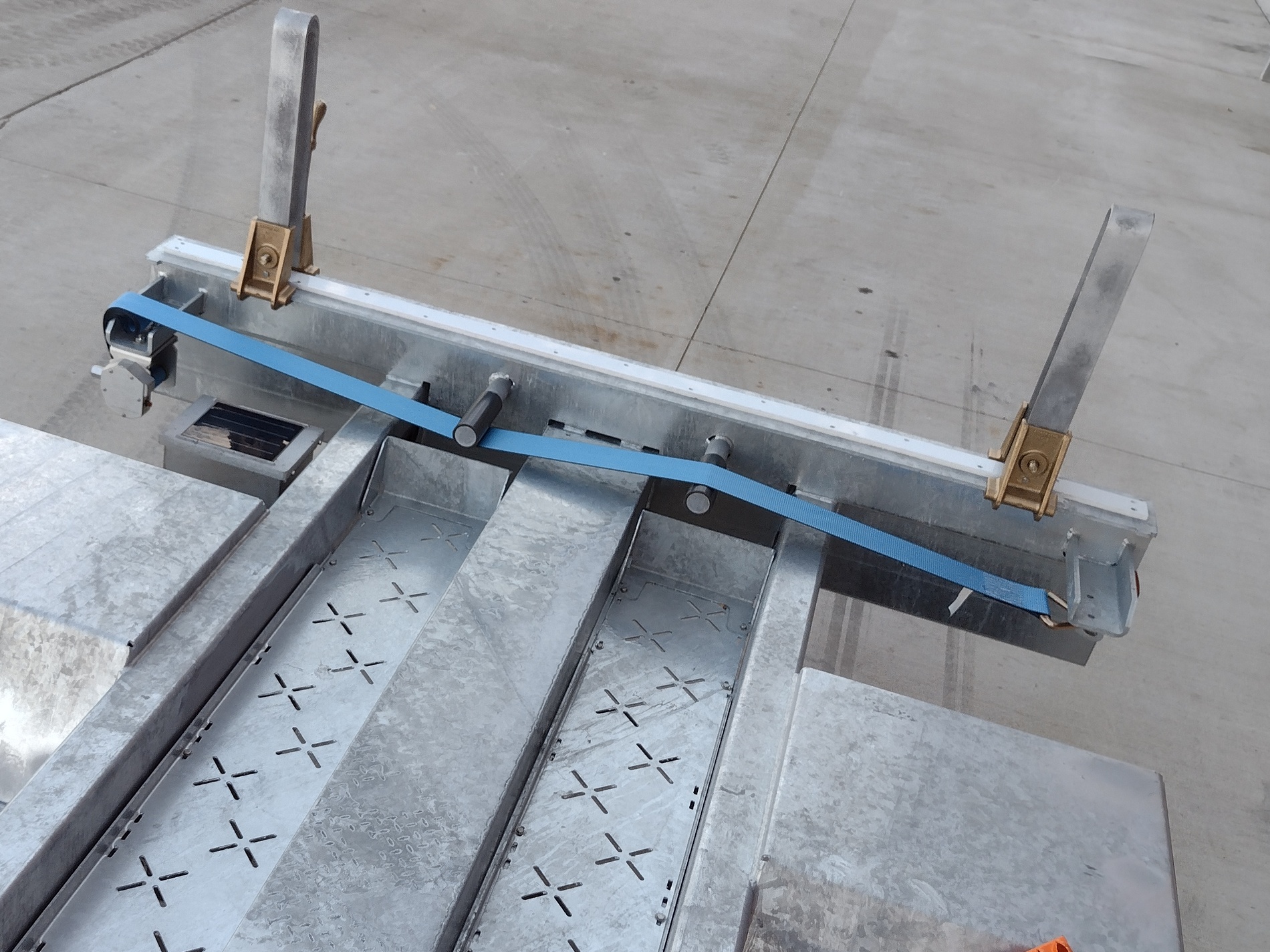

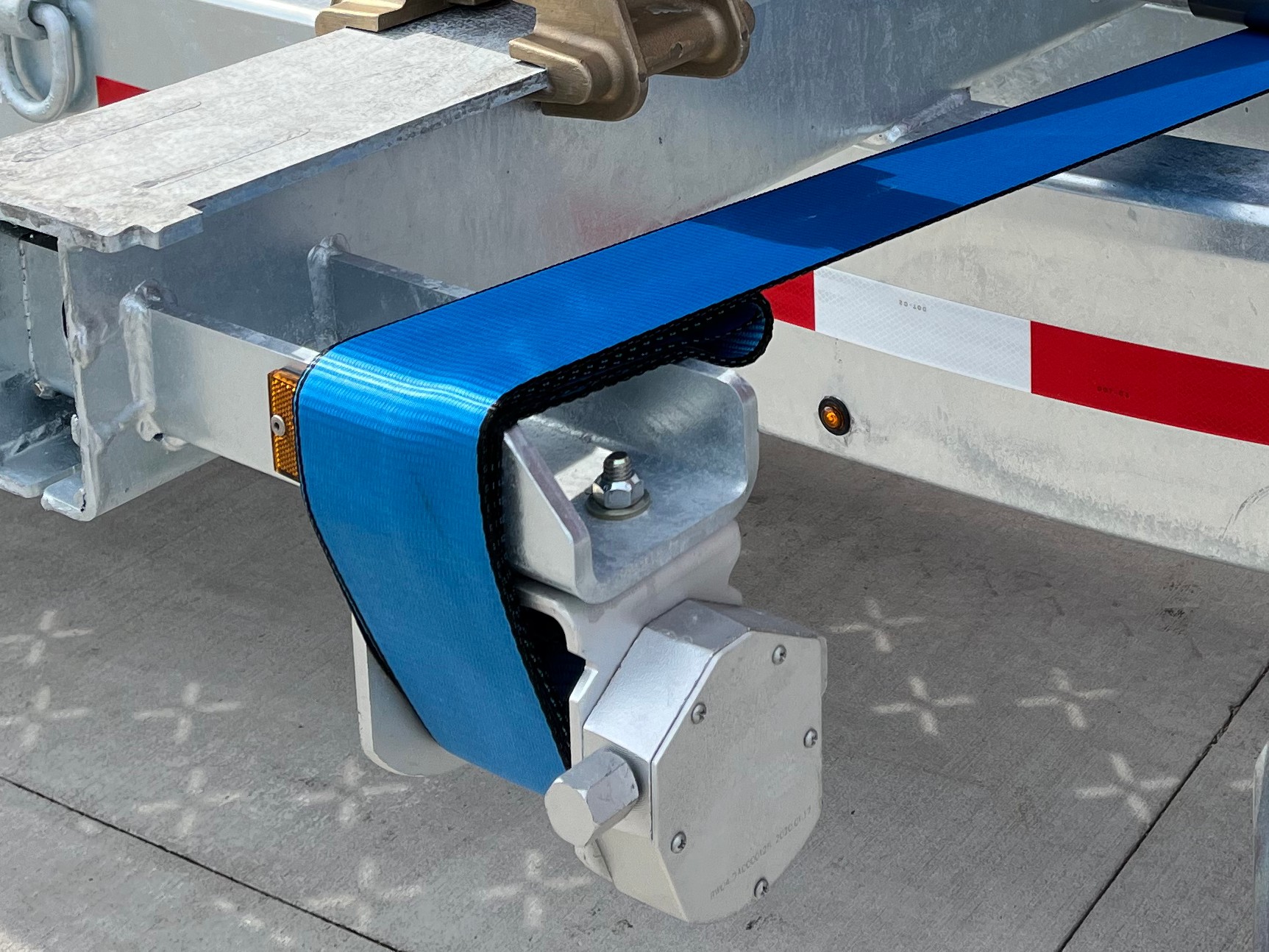

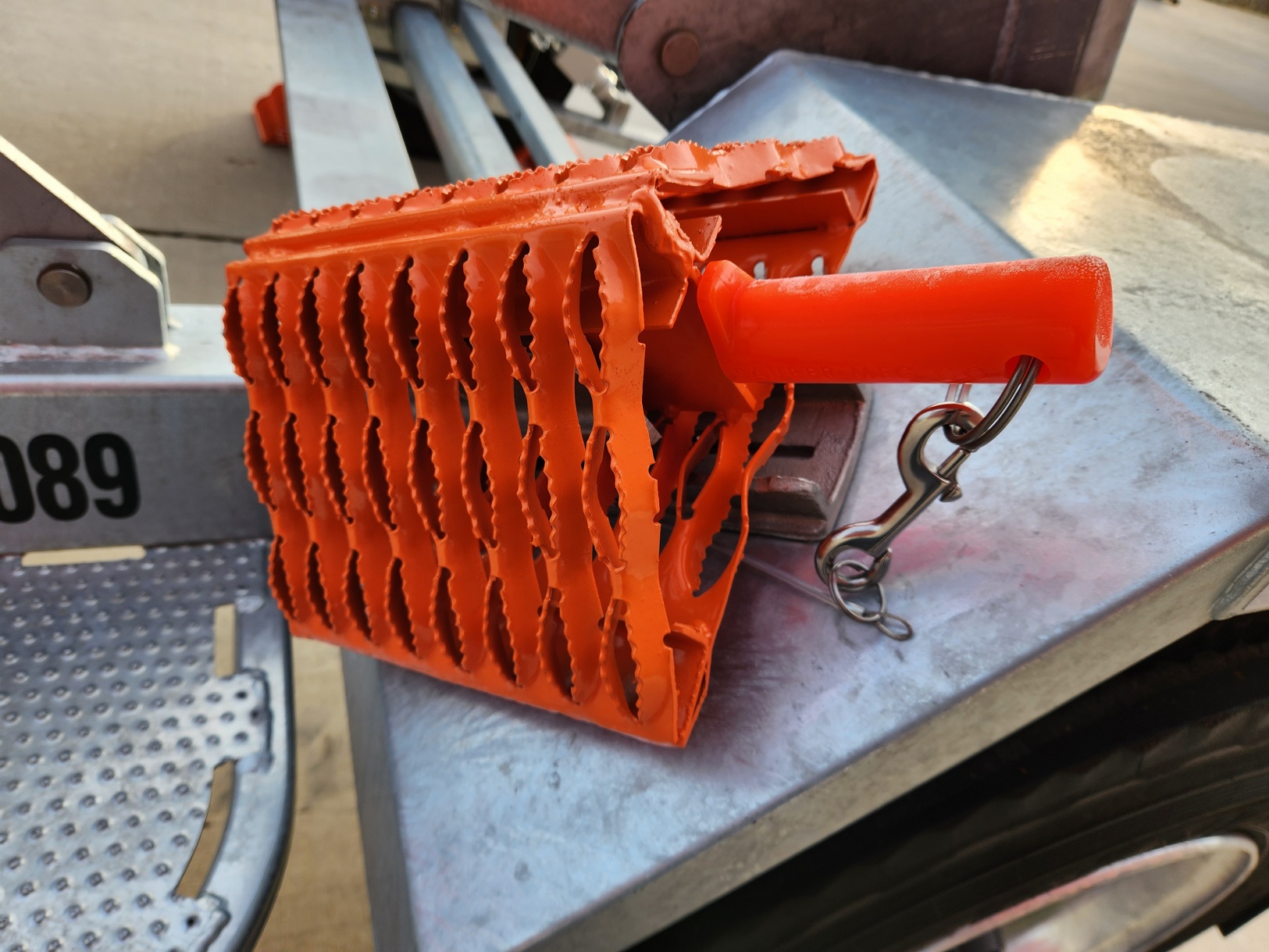

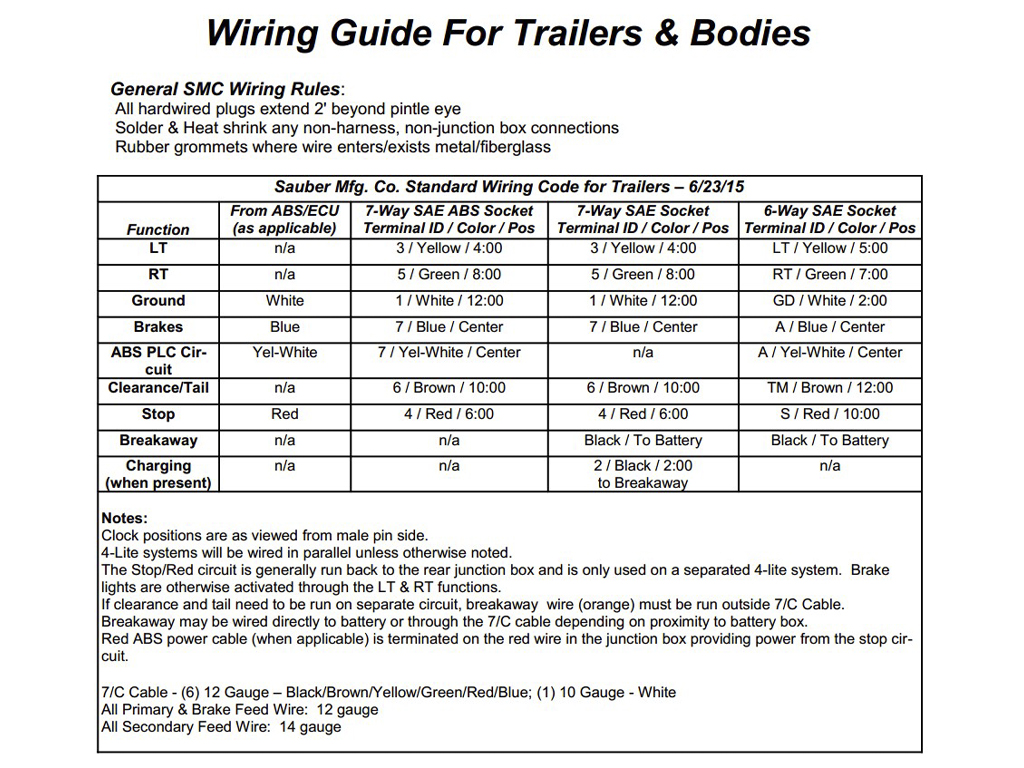

Straight forward pole transport with low tongue weight options will meaningfully improve your work efficiency. This small pole dinkey can include either deep “V” or bolster configurations, integral aluminum light bar and self-locking worm gear drive winch binders, you can make fast work of pole loading and transport. With one of our rated pole muzzles plus electric brake breakaway kits you enhance both safety and compliance. Standard hot dipped galvanized finish, galvanized undercarriage components and a protected wiring harness provide you the durability you need in a small pole dinkey.

Click here to see similar equipment.

Capacity: 3140#

GVWR: 4350#

Dimensions: 10'L x 79"W

Benefits