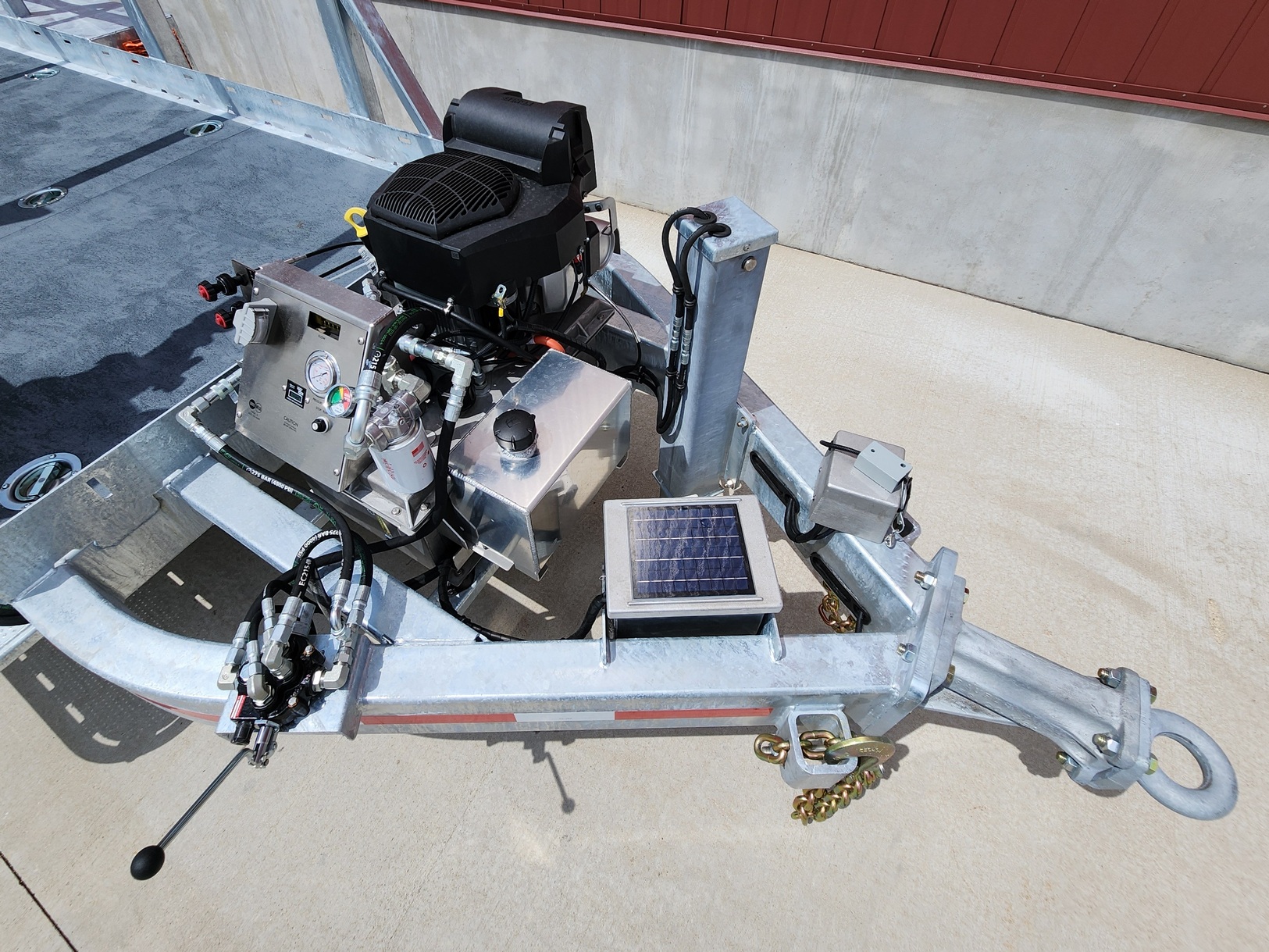

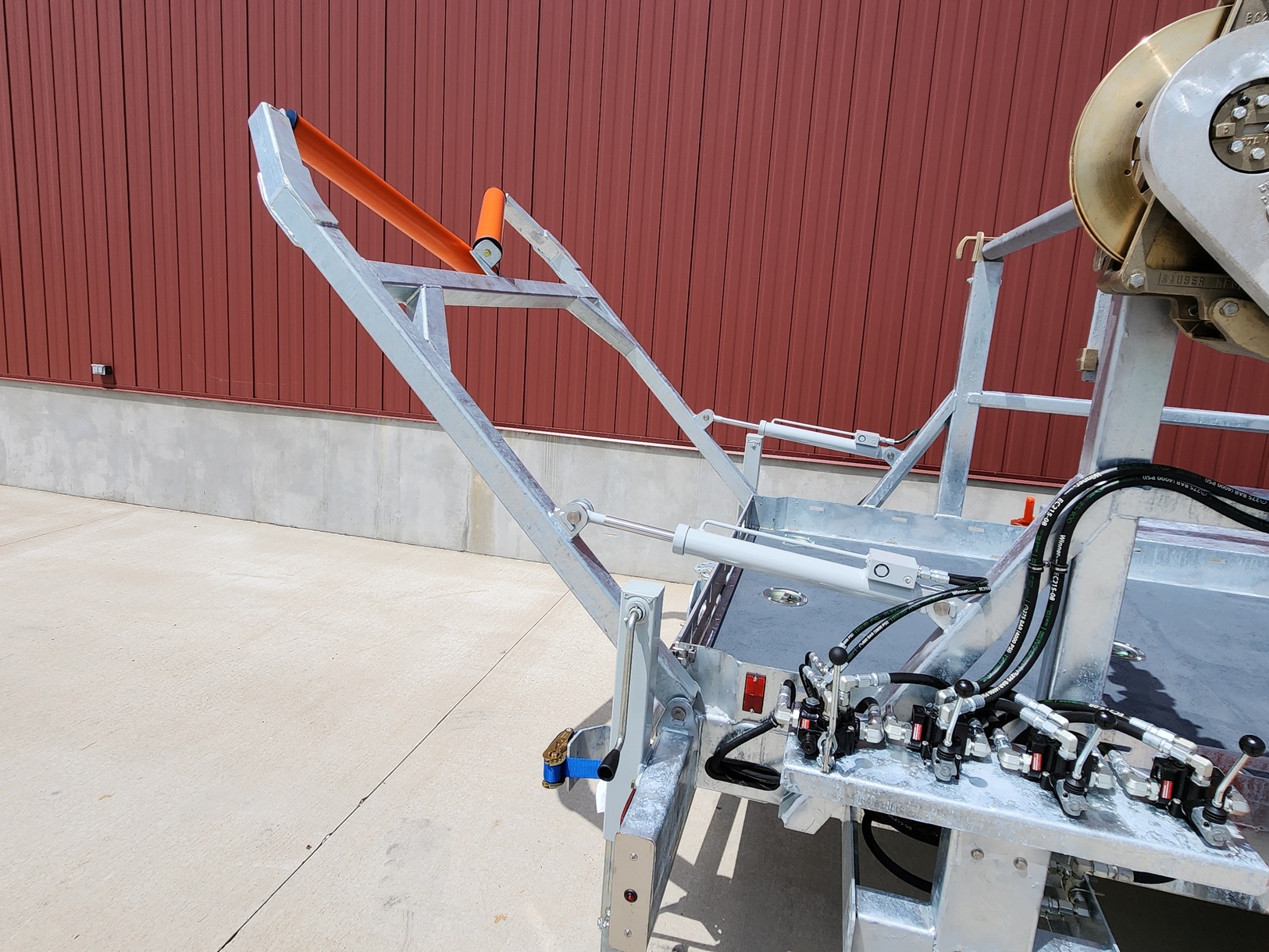

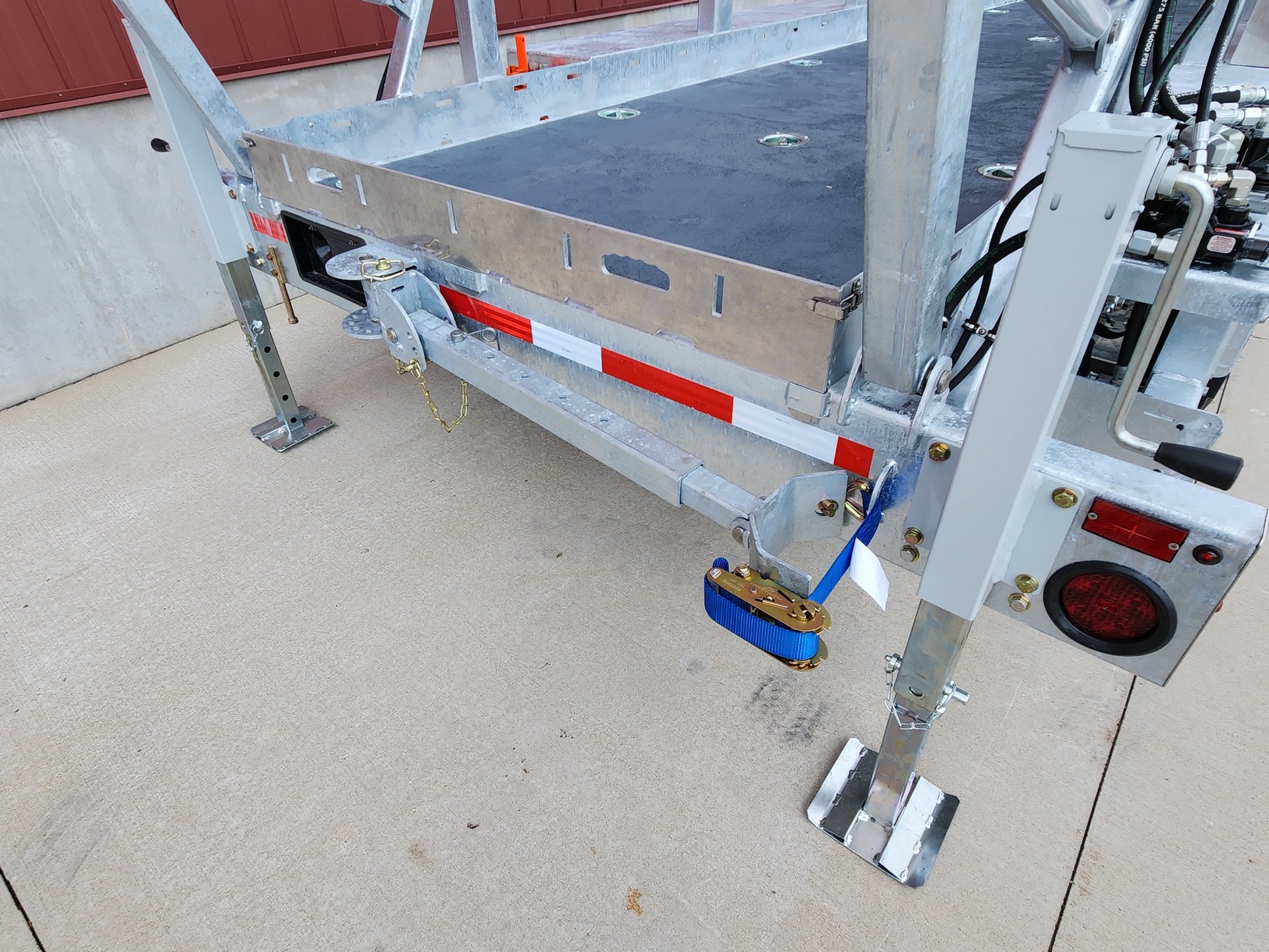

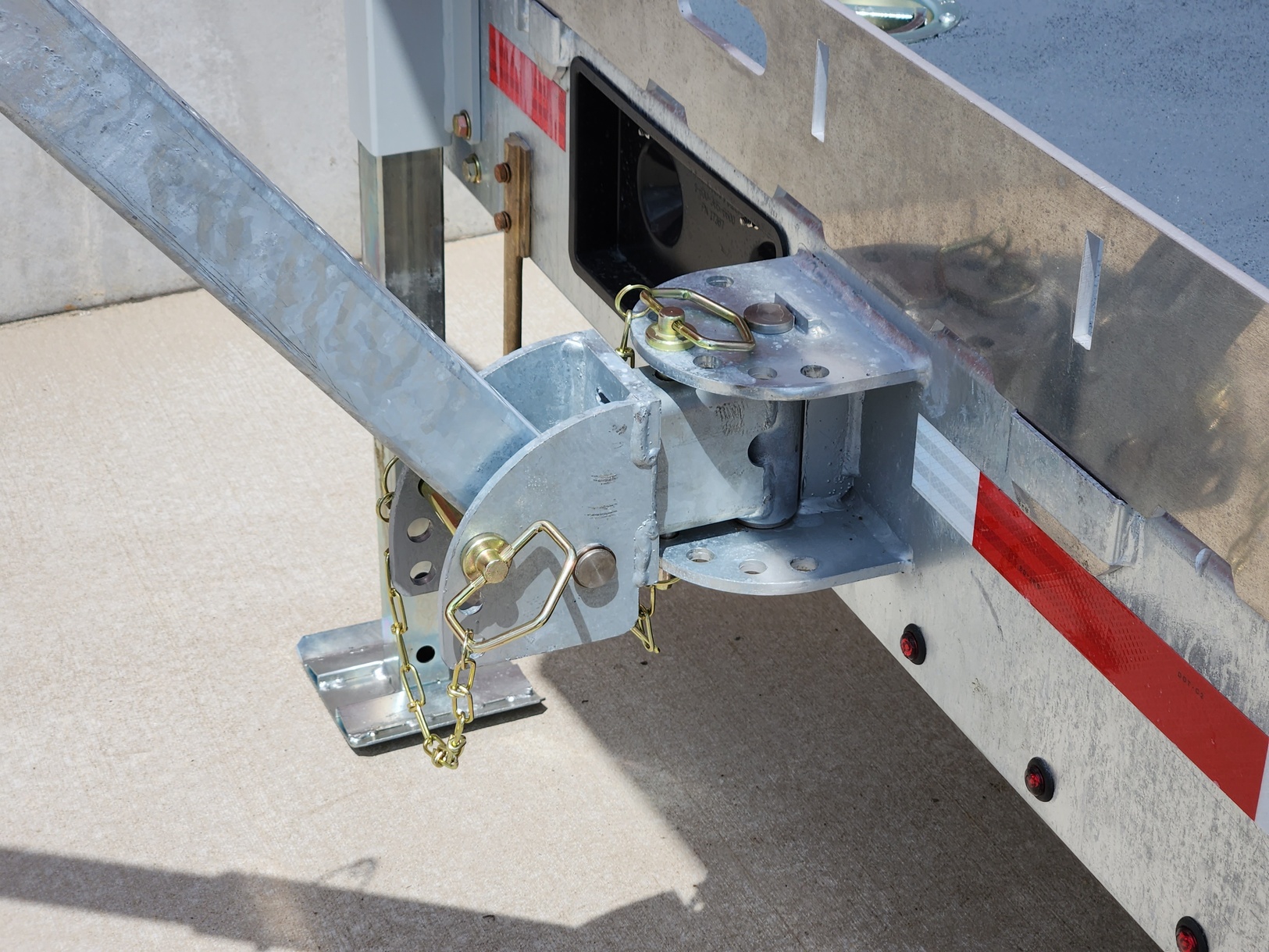

Three Reel Stringing Trailer

Model 1532

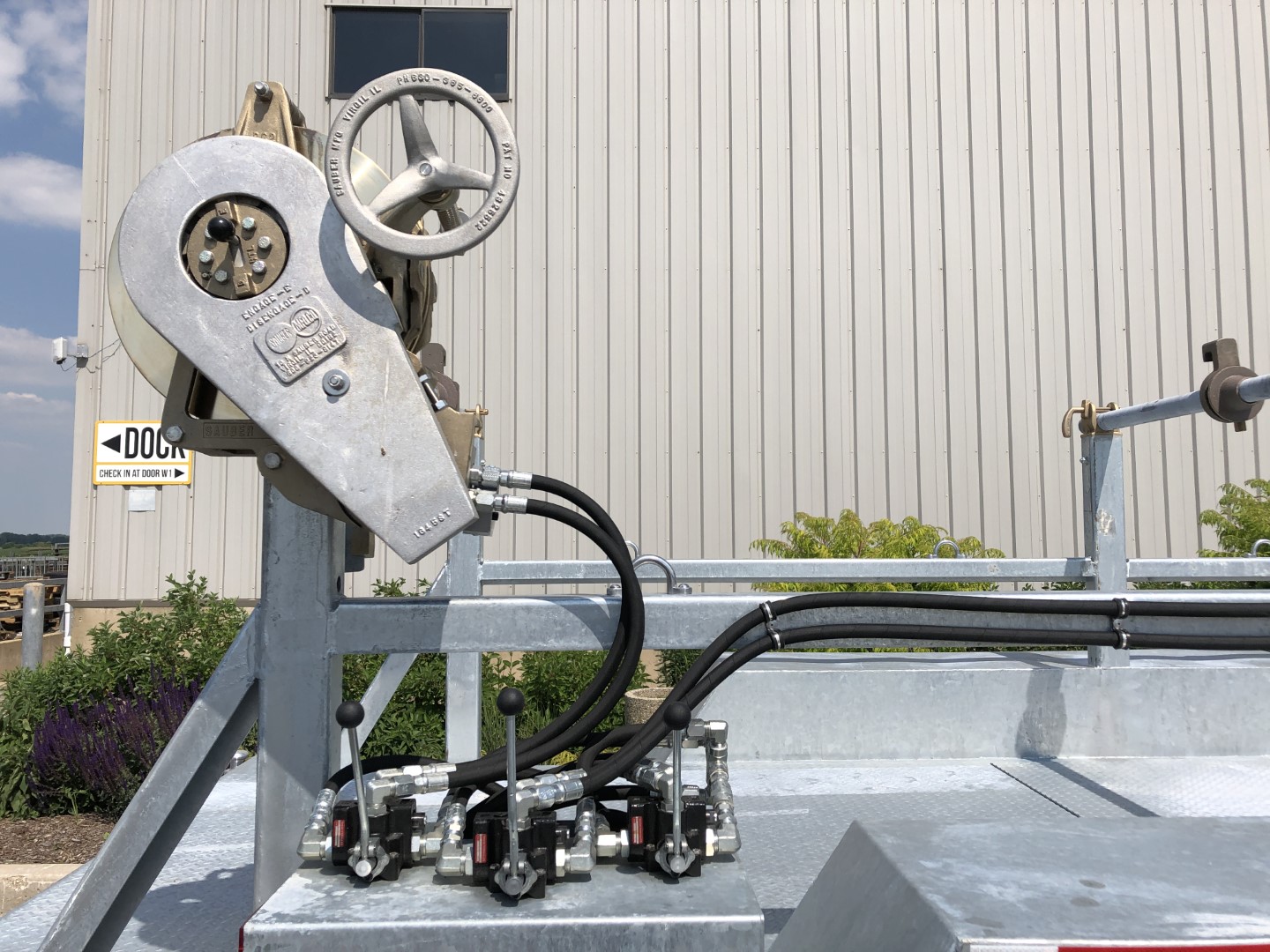

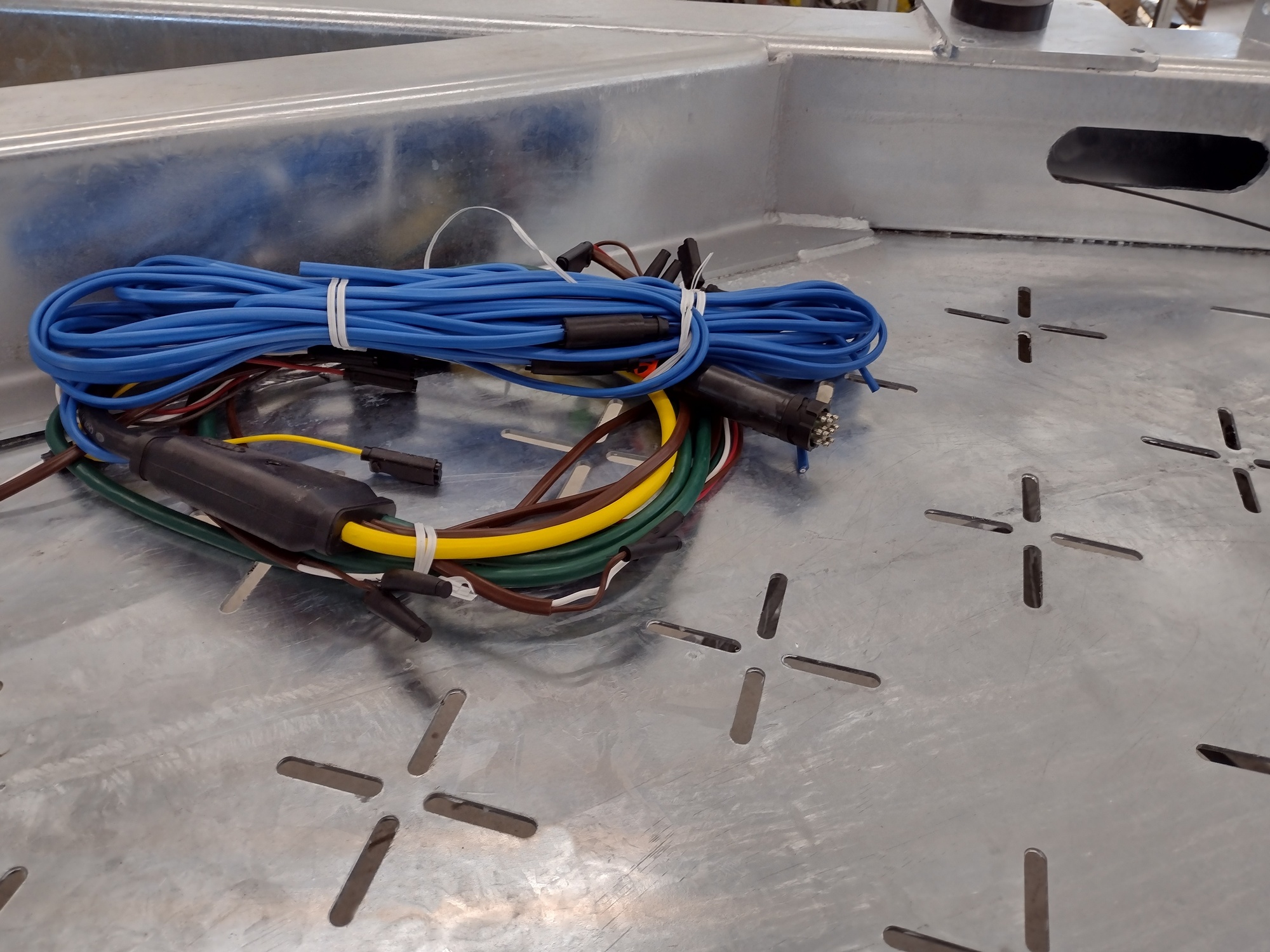

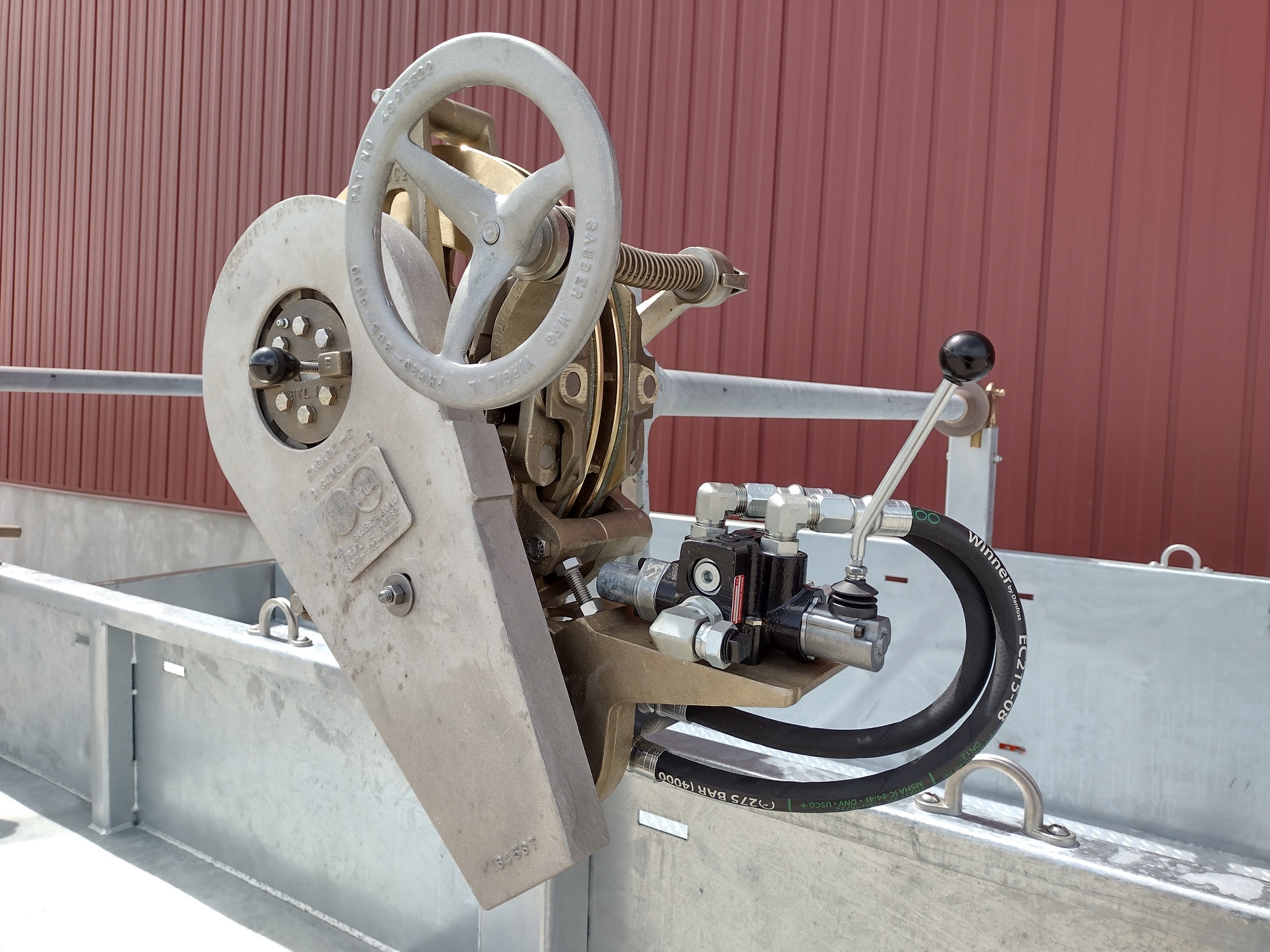

This high capacity three-reel trailer handles your larger reel sizes with ease. Suitable for overhead or underground construction work, you’ll benefit from options for easier reel payout, hydraulic reel control and enhanced onboard storage. Expect long life from your three-reel trailer with features such as bent tube construction, galvanized finish and hidden automotive wiring harness.

Click Here to review trailers with specifications related to the Model 1532 Three Reel Trailer.

Capacity: 28600#

GVWR: 35250#

Reel Size: 78"Dia x 55"W

Dimensions: 25'L x 102"W